Controls & components, Master power switch, Headstock controls – Southbend EVS Tool Room lathe w/DRO SB1059F User Manual

Page 7

For Machines Mfg. Since 3/11

EVS Toolroom Lathe w/DRO

-5-

I N T R O D U C T I O N

Refer to Figures 2–9 and the following

descriptions to become familiar with the features

and basic controls of this lathe. This knowledge

will be necessary to properly set up the lathe for

the test run and spindle break-in.

Controls &

Components

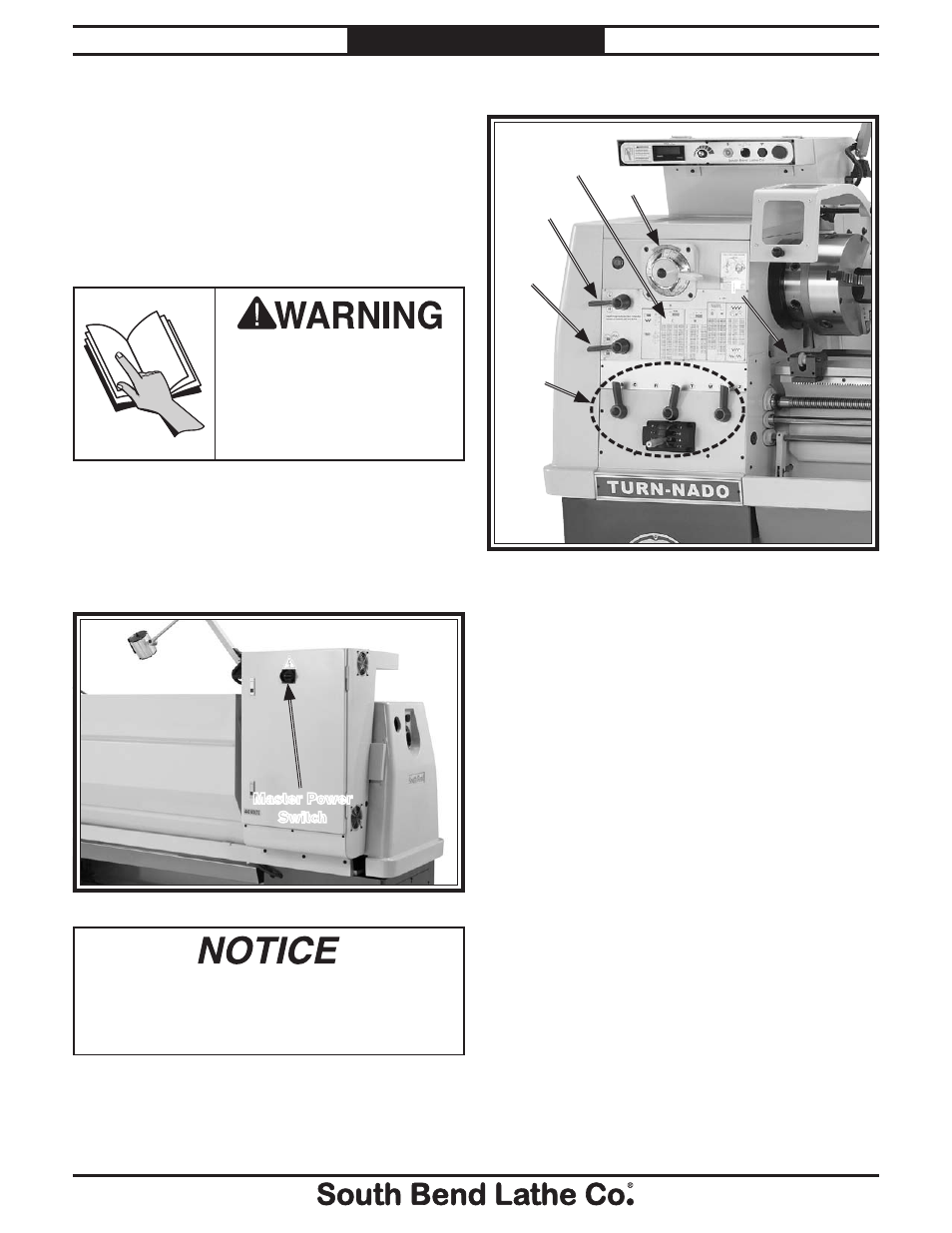

Master Power Switch

The rotary switch shown in Figure 2 toggles

incoming power ON and OFF to the lathe

controls. It also prevents the electrical cabinet

door from being opened when the switch is ON.

To reduce the risk of

serious injury when using

this machine, read and

understand this entire

manual before beginning any

lathe operations.

Figure 2. Location of the master power switch.

Master Power

Switch

Turning the master power switch to OFF is not

a safe alternative to completely disconnecting

the machine from power when wiring,

servicing, or making repairs.

Headstock Controls

A. Quick Change Gearbox Levers:

Controls the

leadscrew and feed rod speed for threading

and feed operations.

B. Headstock Feed Direction Lever:

Controls

the direction that the leadscrew and feed rod

rotate.

C. Gearbox Range Lever:

Shifts the quick-

change gearbox into low range, neutral, or

high range.

D. Threading and Feed Charts:

Displays the

necessary configuration of the gearbox levers

and end gears for different threading or

feeding options.

E. Spindle Speed Range Lever:

Selects one of

four spindle speed ranges.

F. Micrometer

Stop:

Limits carriage travel for

production runs or to make final adjustments

to the carriage position.

Figure 3. Headstock controls.

A

C

F

B

D

E