State Industries GS675YRVIT User Manual

Page 17

17

note: This unit can be vented using only the following

materials: PVC (Cellular Core; ASTM-F891), PVC (DWV; ASTM

D2665 or CSA B181.2), PVC (Sch 40, 80, 120; ASTM D1785 or

CSA B137.3), PVC (SDR Series; ASTM-D2241 or CSA B137.3),

CPVC (CPVC 41; ASTM-D2846 or CSA B137.6), CPVC

(Sch 40, 80; ASTM-F441 or CSA B137.6), CPVC (SDR Series;

ASTM-F442), ABS (Sch 40 DWV; ASTM D2661 or CSA B181.1),

ABS (Sch 40 DWV cellular core; ASTM-F628). The fittings, other

than the TERMINATION should be equivalent to PVC-DWV

fittings meeting ASTM D-2665 (Use CPVC fittings, ASTM F-438

for CPVC pipe and ABS fittings, ASTM D-2661/3311 for ABS

pipe). If CPVC or ABS pipe and fittings are used, then the proper

cement must be used for all joints, including joining the pipe to

the Termination (PVC Material). If local codes do not allow the

use of the PVC termination when a material other than PVC is

used for venting, then an equivalent fitting of that material may

be substituted if the screen in the PVC terminal is removed and

inserted into the new fitting.

PVC Materials should use ASTM D-2564 Grade Cement; CPVC

Materials should use ASTM F-493 Grade Cement and ABS

Materials should use ASTM D-2235 Grade Cement.

If the water heater is being installed as a replacement for an

existing power vented heater in pre-existing venting, a thorough

inspection of the existing venting system must be performed prior

to any installation work. Verify that the correct material as detailed

above has been used, and that the minimum or maximum vent

lengths and terminal location as detailed in this manual have been

met. Carefully inspect the entire venting system for any signs of

cracks or fractures, particularly at the joints between elbows and

other fittings and the straight runs of vent pipe. Check the system

for signs of sagging or other stresses in the joints as a result of

misalignment of any components in the system. If any of these

conditions are found, they must be corrected in accordance with

the venting instructions in this manual before completing the

installation and putting the water heater into service.

note: a. For water heaters in locations with high ambient

temperatures (above 100°F) it is recommended that CPVC or

ABS pipe and fittings be used.

B. A 22.5 degree elbow (2” vent

pipe) or a 45 degree elbow (3” and 4” vent pipe) with an installed

screen VENT TERMINAL must be used in all cases.

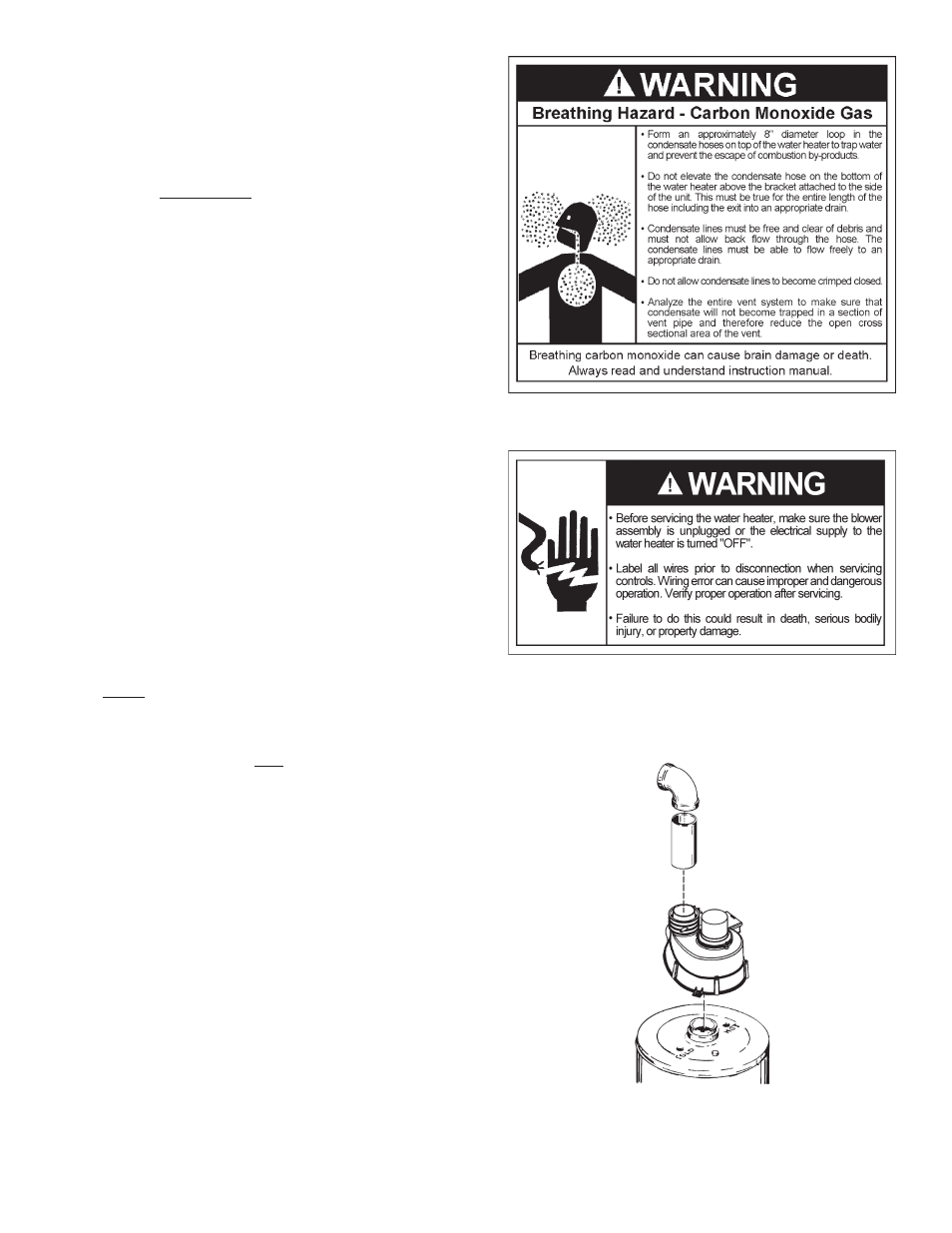

condensate

Condensate formation does not occur in all installations of power

vented water heaters, but should be protected against on installations

where it can form in the venting system. Condensation in the venting

system of power vented water heaters is dependent upon installation

conditions including, but not limited to ambient temperature and

humidity of installation location, ambient temperature and humidity

of venting space, vent discharge and slope, and product usage. In

certain conditions, installations in unconditioned space or having

long horizontal or vertical vent runs may accumulate condensate.

In these conditions, the vent pipe should be sloped downward

away from the blower assembly (not less than 1/8” (3.2 mm) nor

greater than 1/2” (12.7 mm) per foot maximum). If the vent piping

is vented level or sloped upwards away from the blower assembly,

then adequate means for draining and disposing of the condensate

needs to be made by the installer (if condensate is detected). If you

have condensate, then a 3/8” drain hose can be connected to the

built-in drain port of the rubber boot on the blower assembly. For

your convenience, the rubber boot is supplied with a removable cap

on the built-in drain port. Prior to operating the water heater, make

sure the removable cap is installed on the drain port (if a drain hose

is not needed).

Blower asseMBlY InstallatIon

1. Check to make sure that the wire harness is attached to the gas

valve and blower control box.

2. Make sure no material is still attached to the outside or inside

of blower assembly.

fIGure 16. Blower asseMBlY

3. Make sure that plastic tubing is still attached to the pressure

switch and fan housing. Also make sure that wiring connector

from motor to control box is securely attached.