State Industries GS675YRVIT User Manual

Page 15

15

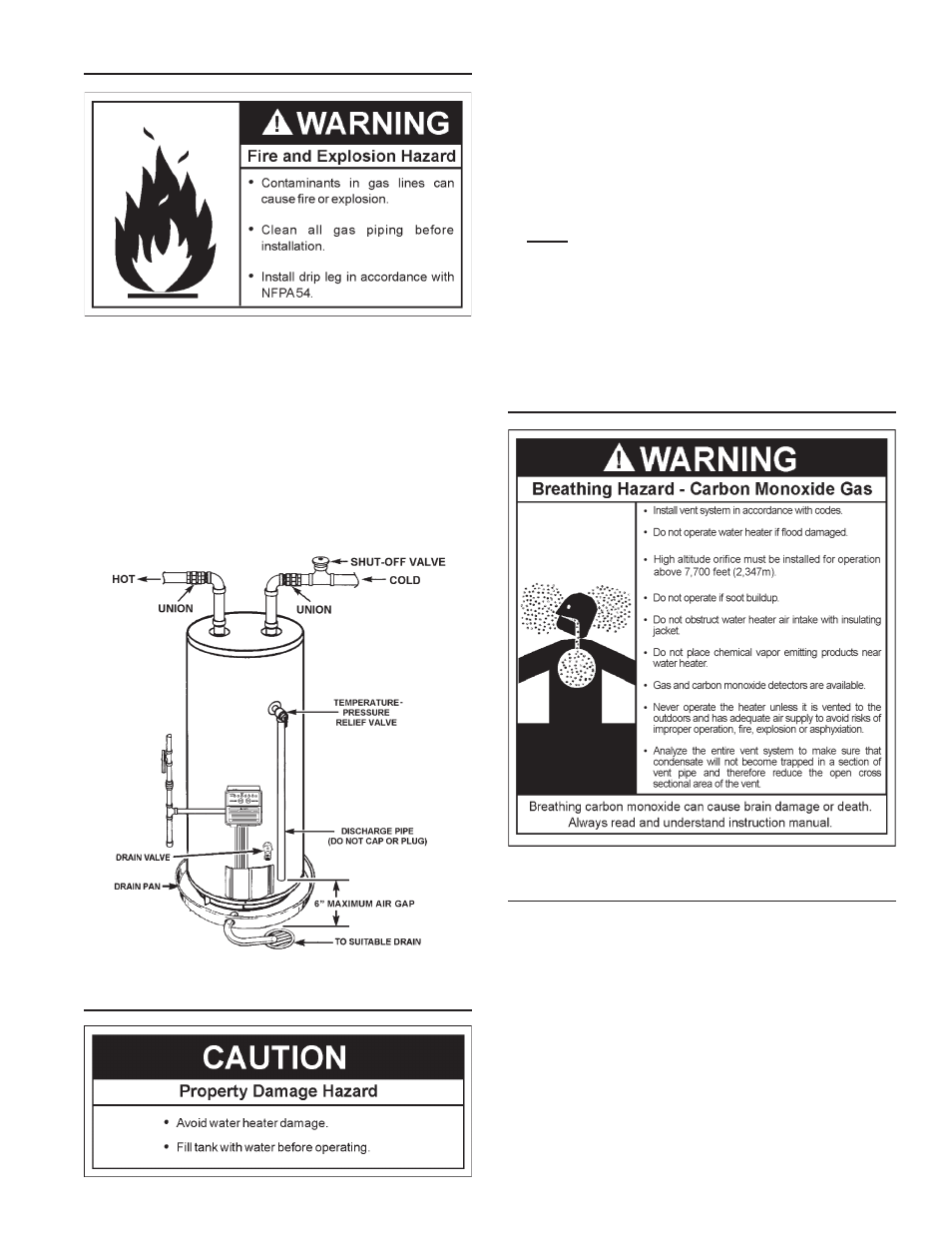

sedIMent traps (drIp leGs)

A sediment trap (drip leg) should be installed as close to the inlet of

the water heater as practical at the time of water heater installation.

The sediment trap should be either a tee fitting with a capped nipple in

the bottom outlet or other device recognized as an effective sediment

trap. If a tee fitting is used, it should be installed in conformance

with one of the methods of installation shown in Figures 12 and 13.

Contaminants in the gas lines may cause improper operation of the

gas control valve that may result in fire or explosion. Before attaching

the gas line be sure that all gas pipe is clean on the inside. To trap

any dirt or foreign material in the gas supply line, a sediment trap

(sometimes called a drip leg) must be incorporated in the piping.

The drip leg must be readily accessible. Install in accordance with

the “Gas Piping” section. Refer to the current edition of the National

Fuel Gas Code (ANSI Z223.1/NFPA 54).

fIGure 14.

fIllInG the water heater

Never use this water heater unless it is completely full of water.

To prevent damage to the tank, the tank must be filled with water.

Water must flow from the hot water faucet before turning “ON” gas

to the water heater.

To fill the water heater with water:

1. Close the water heater drain valve by turning the handle to the

right (clockwise). The drain valve is on the lower front of the

water heater.

2. Open the cold water supply valve to the water heater.

note: the cold water supply valve must be left open when

the water heater is in use.

3. To insure complete filling of the tank, allow air to exit by opening the

nearest hot water faucet. Allow water to run until a constant flow is

obtained. This will let air out of the water heater and the piping.

4. Check all water piping and connections for leaks. Repair as

needed.

ventInG

vent pIpe terMInatIon

The first step is to determine where the vent pipe will terminate, see

Figures 15, 19 and 20. The vent may terminate through the roof as

shown in Figure 20 or through a sidewall as shown in Figure 19.

IMportant

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current edition of the

National Fuel Gas Code, ANSI Z223.1.

For your convenience instructions on proper installation through a

sidewall are provided in Figure 15 and the numbered points below:

1. The exit terminals of a mechanical vent system should be not

less than 7 feet above grade when located adjacent to public

walkways.