Cleaning coolant reservoir, Hazards, Cleaning – Southbend SOUTH BEND LATHE CO.. SB1024 User Manual

Page 58

-56-

For Machines Mfg. Since 8/09

SB1024/SB1025/SB1026

M A I N T E N A N C E

The cavity in the base of the mill can be used

as a coolant reservoir if you choose to install

a recirculating coolant pump accessory. This

reservoir also catches any coolant and debris that

falls from the table and through the screens in

the base.

Hazards

As some coolant ages, it develops dangerous

microbes which eventually proliferate and create

a biological hazard. The risk of exposure to

this hazard can be greatly reduced by cleaning

out the coolant reservoir on a monthly basis or

sooner, if needed based on your daily inspection.

The important thing to keep in mind when

working with coolant is to minimize exposure

to your skin, eyes, and respiratory system

by wearing the proper personal protective

equipment, which includes splash-resistant

safety glasses, long-sleeve gloves, protective

clothing, and a NIOSH-approved respirator.

4.

Place the catch pan under the drain plug,

then remove the plug and allow the fluid to

drain into the pan.

5.

Clean away debris and grime from the

coolant drain screens on the base of the mill.

6.

Use rags, scrapers, and cleaning solvent

to thoroughly clean out the bottom of the

reservoir.

Note:

Use a cleaning solvent that is compatible

with the type of coolant. For instance, if you

are using a water-base coolant, then use a

water-base cleaning solvent.

7.

When the reservoir is clean and dry, replace

the access panel and drain plug.

BIOLOGICAL & POISON

HAZARD!

Use the correct personal

protection equipment when

handling cutting fluid.

Follow Federal, State, and

the coolant manufacturer's

requirement to safely

dispose of the used

coolant.

Cleaning

Tools Needed

Qty

Hex Wrench 3mm ................................................. 1

Hex Wrench 10mm ............................................... 1

Catch Pan .............................................................. 1

To clean out the coolant reservoir:

1.

DISCONNECT MILL FROM POWER!

2.

Put on personal protective equipment.

3.

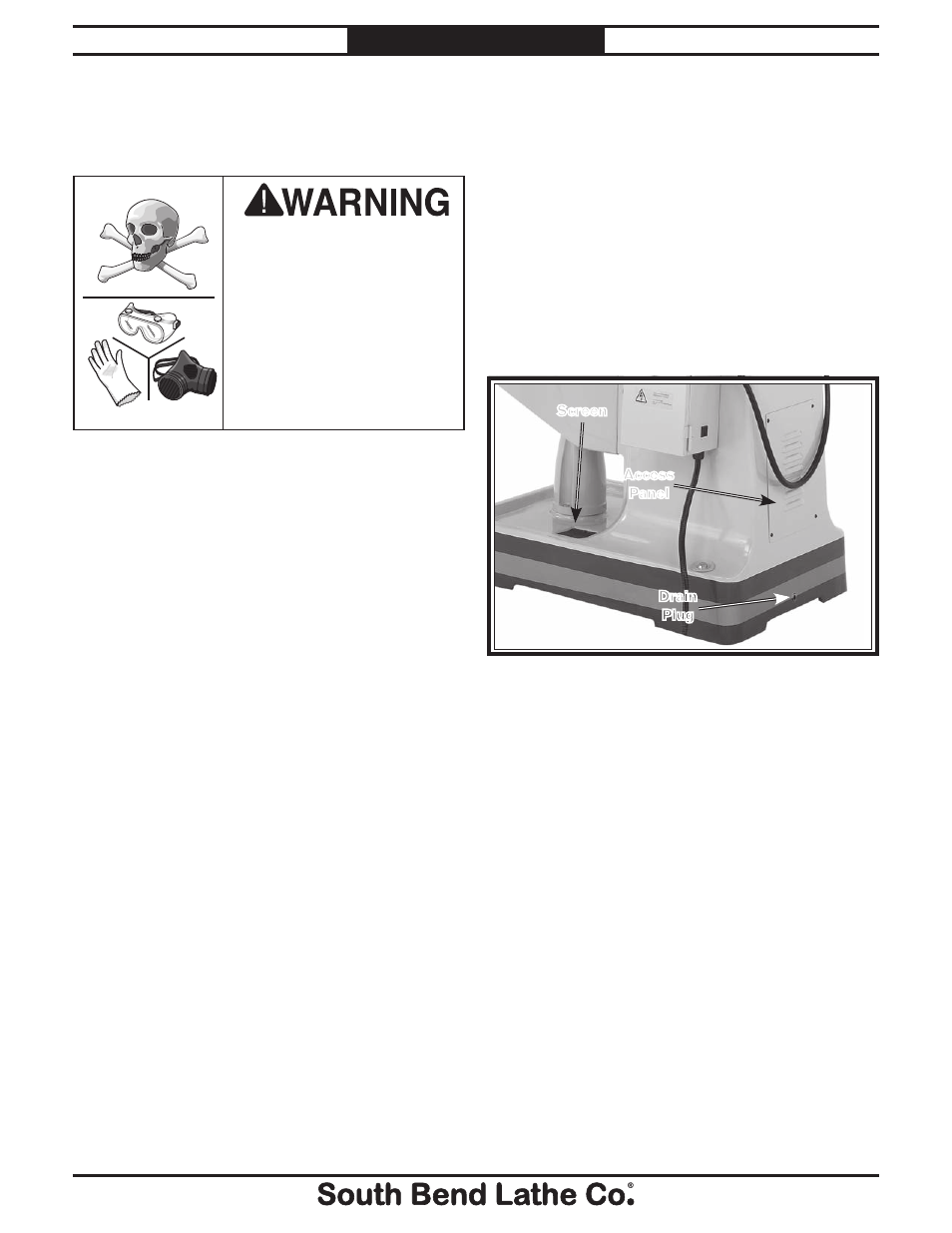

Remove the coolant reservoir access panel

from the rear of the column (see Figure 60).

Cleaning Coolant

Reservoir

Figure 60. Coolant reservoir access panel and drain

plug.

Access

Panel

Drain

Plug

Screen