Maintenance – Jet Tools JOB SITE TABLE SAW JBTS-10MJS User Manual

Page 28

28

Maintenance

General Maintenance

For your own safety, turn the

switch OFF and remove the switch key. Remove

the plug from the power source outlet before

maintaining or lubricating your saw.

1. Clean out all sawdust that has accumulated

inside the saw cabinet and the motor.

2. Polish the saw table with an automotive wax to

keep it clean and to make it easier to slide the

workpiece.

3. Clean cutting blades with pitch and gum

remover.

4. A worn, cut, or damaged power cord should be

replaced immediately.

All electrical or mechanical

repairs should be attempted only by a trained

repair technician. Contact customer service for

assistance. Use only identical replacement parts.

Any other parts may create a hazard.

5. Use liquid dishwashing detergent and water to

clean all plastic parts.

Note: Certain cleaning chemicals can damage

plastic parts.

6. Avoid use of cleaning chemicals or solvents,

ammonia and household detergents containing

ammonia.

Blade Raising and Tilting Mechanism

After every five hours of operation, the blade raising

mechanism and tilting mechanism should be checked

for looseness, binding, or any other abnormalities.

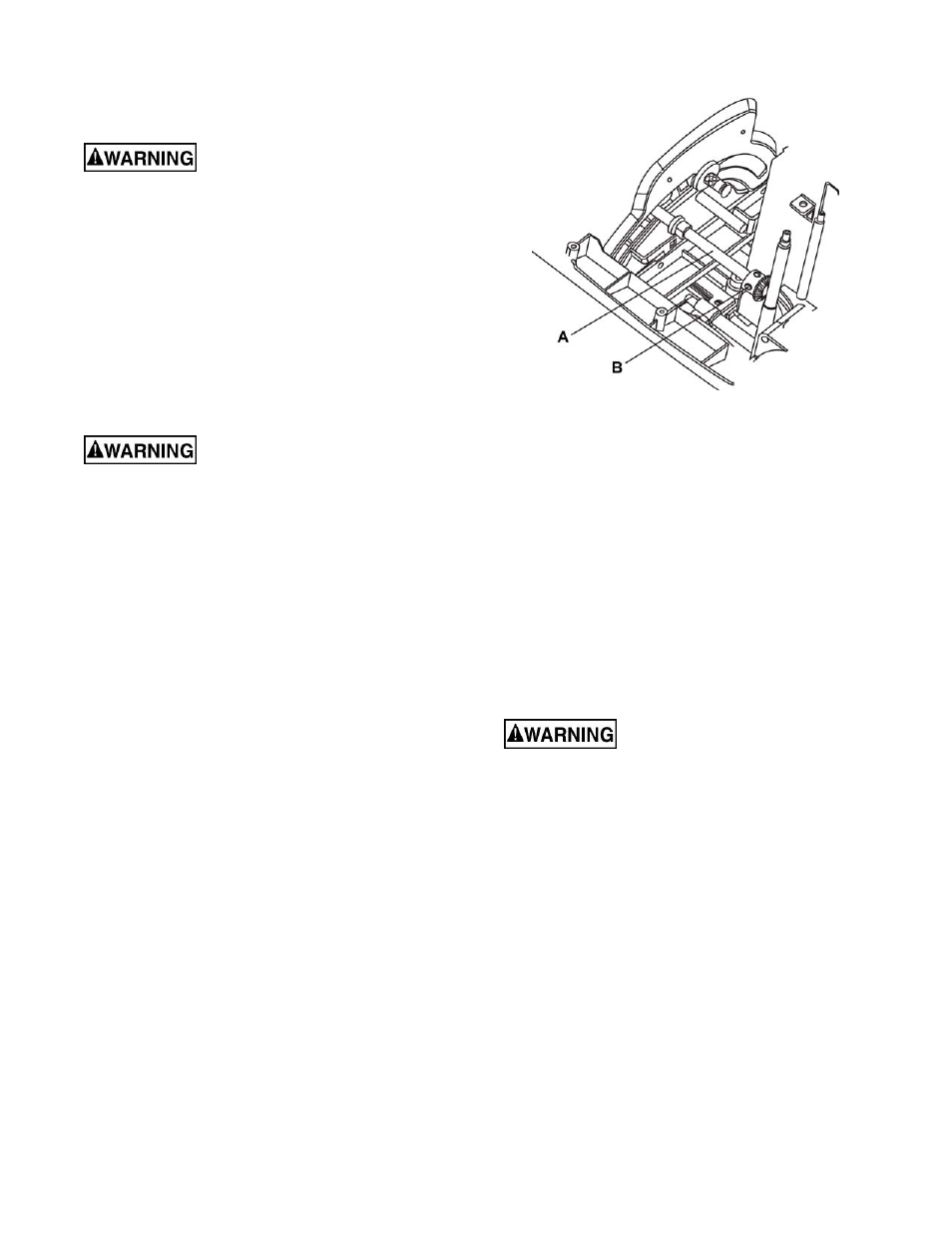

Referring Figure 43:

1. With the saw disconnected from the power

source, turn the saw upside down and pull up

and push down on the motor unit.

2. Observe any movement of the motor mounting

mechanism. Looseness or play in the blade raising

screw rod (A) should be limited to 1/8” or less.

3. If excessive looseness is observed in any other

parts of the blade raising mechanism or tilting

mechanism, take the complete unit to a Service

Center.

Place a small amount of dry lubricant on the bevel

gear (B). The screw rod (A) must be kept clean and

free of sawdust, gum, pitch, and other contaminants

for smooth operations.

Figure 43

If excessive looseness is observed in any part of the

blade raising mechanism or tilting mechanism, take

the complete unit to a Service Center.

Lubrication

All motor bearings are permanently lubricated at the

factory and require no additional lubrication.

On all mechanical parts of your table saw where a

pivot or threaded rod is present, lubricate using

graphite or silicone. These dry lubricants will not

hold sawdust as would oil or grease.

Replacing the Carbon Brushes

Always disconnect the plug from

the power source before inspecting the brushes.

The carbon brushes included with the unit will last

approximately 50 hours of running time, or 10,000 ON/

OFF cycles. Replace both carbon brushes when either

has less than 1/4 in. length of carbon remaining, or if

the spring or wire is damaged or burned.

1. Remove the blade guard, blade, rip fence, miter

gauge and stand assembly from the table saw.

2. Place cardboard or an old blanket on the floor to

protect the saw table surface.

3. Place the saw upside down on the protective

material.

4. Tilt the blade elevation/tilting handwheel (A, Fig. 44)

to the 45° position.