Blade parallel to the miter slot, Additional blade adjustments – Jet Tools JOB SITE TABLE SAW JBTS-10MJS User Manual

Page 20

20

Blade Parallel to the Miter Slot

To avoid injury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

This adjustment was made at the factory, but it

should be rechecked and adjusted if necessary.

This adjustment must be correct to assure accurate

cuts and to prevent the possibility of kickback,

which can result in serious injury.

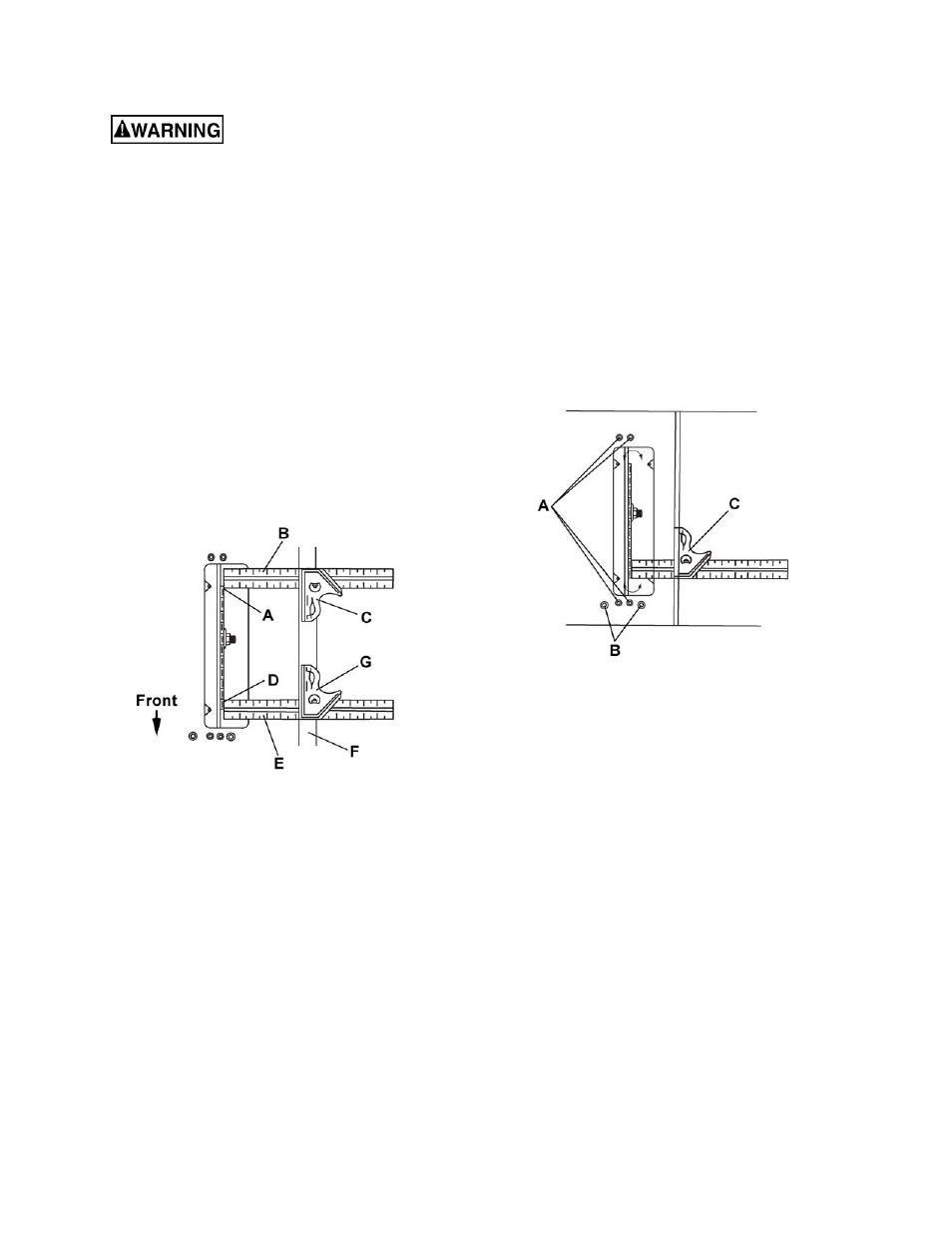

Referring to Figure 22:

1. Remove the yellow switch key and unplug the saw.

2. Remove the blade guard.

3. Raise the blade to the maximum height and set

the bevel angle at 0°

4. Select and mark with a felt tip marker, one

blade tooth with a “right set” angle and position

this tooth at the front of the saw approximately

1/2 in. above the table (D) .

Figure 22

5. Place the combination square base (G) into the

right side miter gauge slot (F) flush against the

inside of the miter gauge slot.

6. Adjust the ruler (E) so it touches the front

marked tooth (D) and lock ruler so it holds its

position in the square assembly.

7. Next rotate the blade, moving the marked tooth

(D) to its new position (A) at the rear of the

saw.

8. Carefully move the combination square from

position (G) to (C).

9. If the ruler touches the marked tooth at the

front and rear position (E at D, B at A), no

adjustment is needed. If not, perform the

adjustment procedure described in the next

section.

Additional Blade Adjustments

Refer to Figure 23.

If the front and rear measurements are not the

same:

1. Remove the combination square (C) and

loosen the four adjusting screws (A) on the top

of the table about a half turn.

2. Cover the blade with a folded piece of

cardboard to protect your hands. Move the

blade and motor mounting rod carefully to the

left or right as much as needed to align the

blade correctly.

3. Tighten the four screws (A) and remeasure, as

described in steps 4 to 9 in the previous section.

Figure 23

4. If sufficient adjustment cannot be made by the

four adjusting screws (A), then also loosen the

two adjusting screws (B) and repeat all

previous steps. Loosen these screws (B) only if

necessary as they are set for accurate 90° and

45° settings.

5. Recheck the blade clearance making sure that

the blade does not hit the table insert or other

parts when at the 90° and 45° settings.

6. Retighten all four adjusting screws (A) and

reset the 90° and 45° setting as described in

the 90° and 45° Positive Stop Adjustment

section (page 19).