English – Middleby Cooking Systems Group PS536 User Manual

Page 23

23

ENGLISH

SECTION 4 - MAINTENANCE

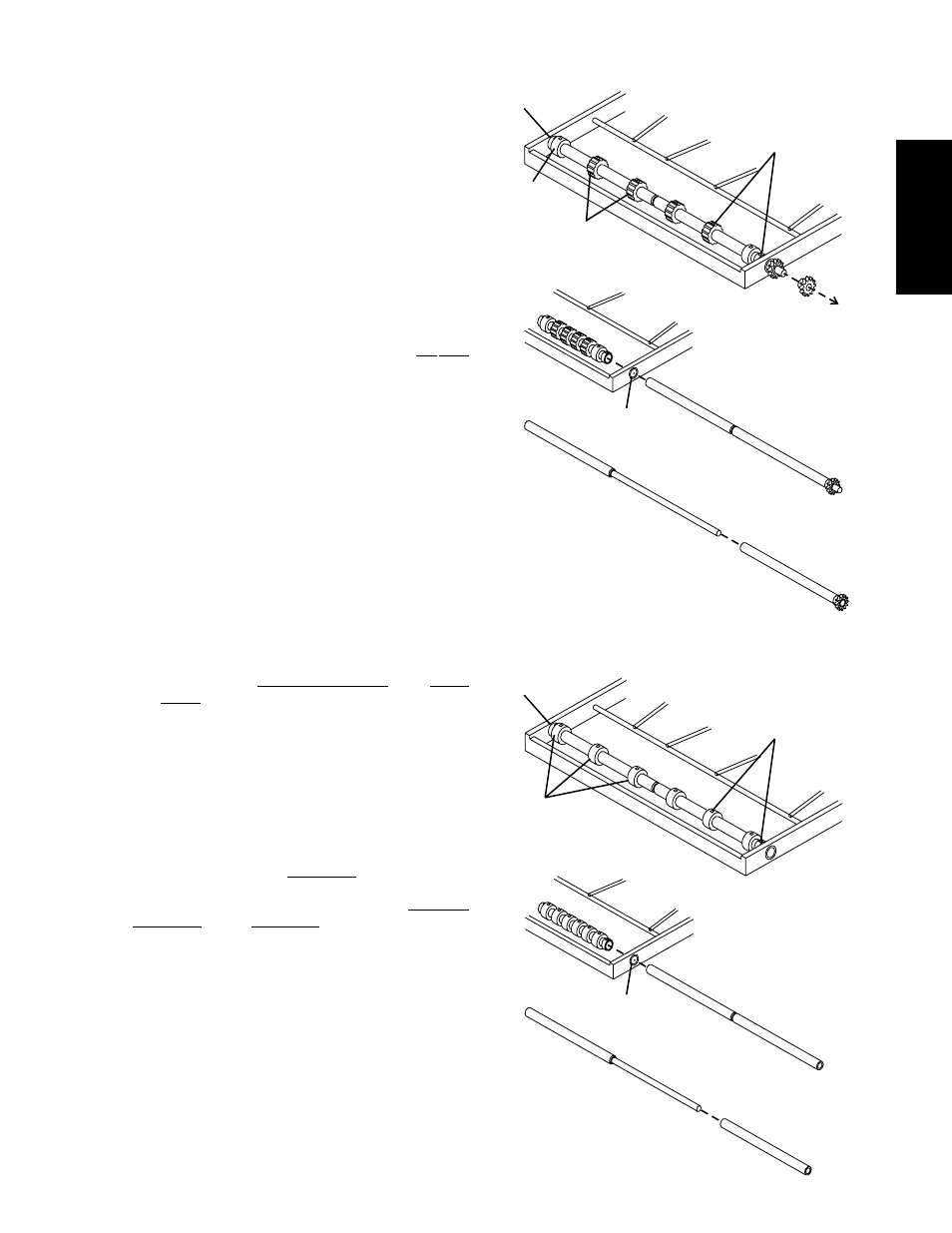

3. Disassemble and clean the drive and idler shafts

using the following procedure.

a. Loosen (DO NOT REMOVE) the set screw on the

outer drive sprocket. Then, slide the drive sprocket

off the end of the drive shaft. See Figure 4-4.

b. Loosen (DO NOT REMOVE) the set screws on all

four steel spacers (2 per shaft), AND on all twelve

conveyor belt sprockets (6 per shaft).

c. Gently work the shaft sections out of the conveyor

frame, removing the conveyor belt sprockets as

necessary. See Figures 4-4 and 4-5.

d. Slide the two sections of each shaft apart.

e. Clean all of the shaft components thoroughly

using a rag. Then, lubricate each solid inner shaft,

AND the interiors of each hollow shaft, using an

FDA-approved light food-grade lubricant. DO NOT

lubricate the shafts using WD40 or a similar

product. This can cause the shafts to wear rapidly.

f.

Slide the hollow shaft sections over the solid inner

shafts. Check that the hollow section that has a

drive sprocket attached is placed at the end of the

the drive shaft.

g. Slide the reassembled shafts into the conveyor

frame. As the shafts are replaced, slide the steel

spacers and conveyor belt sprockets onto the

shafts. Refer to Figures 4-4 and 4-5.

h. After the shafts are properly aligned, position the

steel spacers against the ends of the bushings

on the conveyor frame. Tighten the set screws on

the spacers to hold them in place. Leave the

conveyor belt sprockets loose at this time.

i.

Replace the outer drive sprocket. Tighten its set

screw to hold it in place.

j.

Refer to Part D, Conveyor Installation, in the Instal-

lation section of this Manual to replace the con-

veyor belt. As you replace the belt, position the

conveyor belt sprockets.

k. After the belt is in place and the sprockets are

correctly positioned, tighten the set screws to hold

the sprockets in place.

4. Reinstall the end plugs and conveyor onto the oven.

5. Reattach the drive chains. Replace the chain cover.

7. Check the tension of the conveyor belt as shown in

Figure 2-9 (in Section 2, Installation). The belt should

lift between 1-2" (25-50mm). If necessary, adjust the

belt tension using the procedure in Part D (Conveyor

Installation) in the Installation section of this Manual.

8. Replace the crumb trays and exit tray onto the oven.

Figure 4-5 - Disassembling the idler shaft

1. Remove outer

drive sprocket

Figure 4-5 - Disassembling the drive shaft

2. Loosen set

screws on belt

sprockets and

spacers (8)

3. Slide shafts out

of frame

Bushing

4. Disassemble,

clean, and

lubricate shafts

Smooth

sprocket (2)

Sprockets

w/teeth (4)

Spacer (2)

1. Loosen set

screws on belt

sprockets and

spacers (8)

2. Slide shafts out

of frame

Bushing

3. Disassemble,

clean, and

lubricate shafts

Smooth

sprockets (6)

Spacer (2)