English – Middleby Marshall Model PS536 User Manual

Page 4

4

ENGLISH

Ovens with

Ovens with

Ovens with

Ovens with

1422mm-long

1524mm-long

1524mm-long

1930mm-long

Type 1 conveyor*

Type 1 conveyor*

Type 2 conveyor*

Type 2 conveyor*

(custom)

(standard)

(standard)

(custom)

Overall Height: single oven w/standard 446mm legs

1105mm

1105mm

1105mm

--

single oven w/custom 597mm legs

--

1256mm

1256mm

--

double oven w/standard 446mm legs 1549mm

1549mm

1549mm

--

double oven w/custom 521mm legs

--

1624mm

1624mm

1624mm

triple oven w/standard 152mm legs

1702mm

1702mm

1702mm

--

Overall Depth:

without optional front window

1010mm

1010mm

1010mm

1010mm

with optional front window

1092mm

1092mm

1092mm

1092mm

Overall Length: without exit tray installed

1422mm

1524mm

1537mm

1943mm

with exit tray installed

--

1734mm

1734mm

2140mm

Baking Chamber Length

< - - - - - - - - - - - - - - - - - - 914mm - - - - - - - - - - - - - - - - - - >

Conveyor Width: Single Belt

< - - - - - - - - - - - - - - - - - - 508mm - - - - - - - - - - - - - - - - - - >

Split Belt

< - - - - - - - - - - - - - - - - - 2 x 241mm - - - - - - - - - - - - - - - - - >

Conveyor Length

1422mm

1524mm

1524mm

1930mm

Recommended Minimum Clearances:

Rear of oven to wall

< - - - - - - - - - - - - - - - - - - 76mm - - - - - - - - - - - - - - - - - - >

Control end of conveyor to wall

< - - - - - - - - - - - - - - - - - - 457mm - - - - - - - - - - - - - - - - - - >

Non-control end of conveyor to wall

< - - - - - - - - - - - - - - - - - - 76mm - - - - - - - - - - - - - - - - - - >

* Refer to Figures 2-9 and 2-10 in the Installation section for illustrations of Type 1 and Type 2 conveyors.

SECTION 1 - DESCRIPTION

I. OVEN USES

PS536 Ovens can be used to bake and/or cook a wide

variety of food products, such as pizza, pizza-type products,

cookies, sandwiches and others.

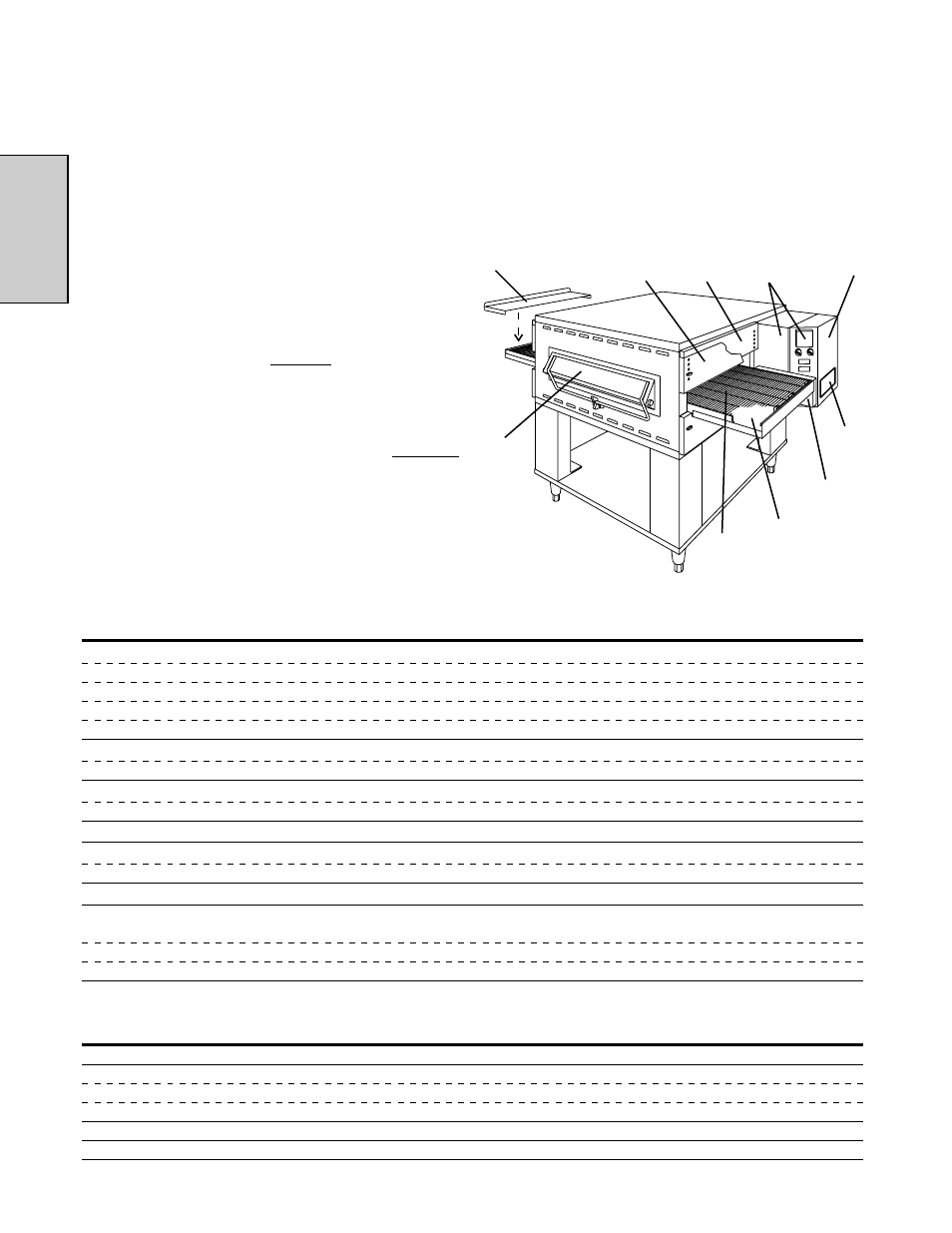

II. OVEN COMPONENTS - see Figure 1-1.

A. Window (on ovens so equipped): Allows the user to see

and access food products inside the baking chamber.

B. Conveyor Exit Tray: Prevents food products from falling off

the end of the moving conveyor.

C. Eyebrows (on ovens so equipped): Can be adjusted to

various heights to prevent heat loss into the environment.

D. End Plugs: Allow access to the oven's interior.

E. Control Panel: Location of the operating controls for the

oven. Refer to Section 3, Operation, for details.

F. Machinery Compartment Access Panel: Allows access

to the oven's interior components. No user-servicable

parts are located inside the machinery compartment.

G. Serial Plate: Provides specifications for the oven that affect

installation and operation. Refer to Section 2, Installation,

for details.

H. Conveyor Drive Motor: Moves the conveyor.

I.

Crumb Pans: Catch crumbs and other material that drop

through the conveyor belt. One crumb pan is located

underneath each end of the conveyor.

J. Conveyor: Moves the food product through the oven.

Fig. 1-1 - Oven Components

A

Table 1-2: General specifications (per oven cavity)

Weight

182kg

Rated Heat Input: Gas Ovens, Natural Gas

14.6kW-hr.

Gas Ovens, Propane

13.2kW-hr.

Electric Ovens

17kW

Operating Temperature

93-316°C

Warmup Time

25 minutes

B

J

G

E

D

C

I

F

Not Shown:

K. Gas Burner (gas ovens) or Heating Elements (electric

ovens): Heat air, which is then projected to the air fingers

by the blowers.

L. Blowers: Fans that project hot air from the burner or

heating elements to the air fingers.

M. Air Fingers: Project streams of hot air onto the food

product.

H

III. OVEN SPECIFICATIONS

Table 1-1: Dimensions