English, Iv. maintenance - every 6 months – Middleby Marshall Model PS536 User Manual

Page 32

32

ENGLISH

SECTION 4 - MAINTENANCE

IV. MAINTENANCE - EVERY 6 MONTHS

A. Check that the oven is cool and the power is disconnected, as

described in the warning at the beginning of this Section.

B. Check for excessive wear on the conveyor drive motor

brushes. The brushes should be replaced if they have

worn to less than 6.4mm in length. Be sure to replace the

brushes in exactly the same position.

C. Check the conveyor drive shaft bushings and spacers.

Replace the components if they are worn.

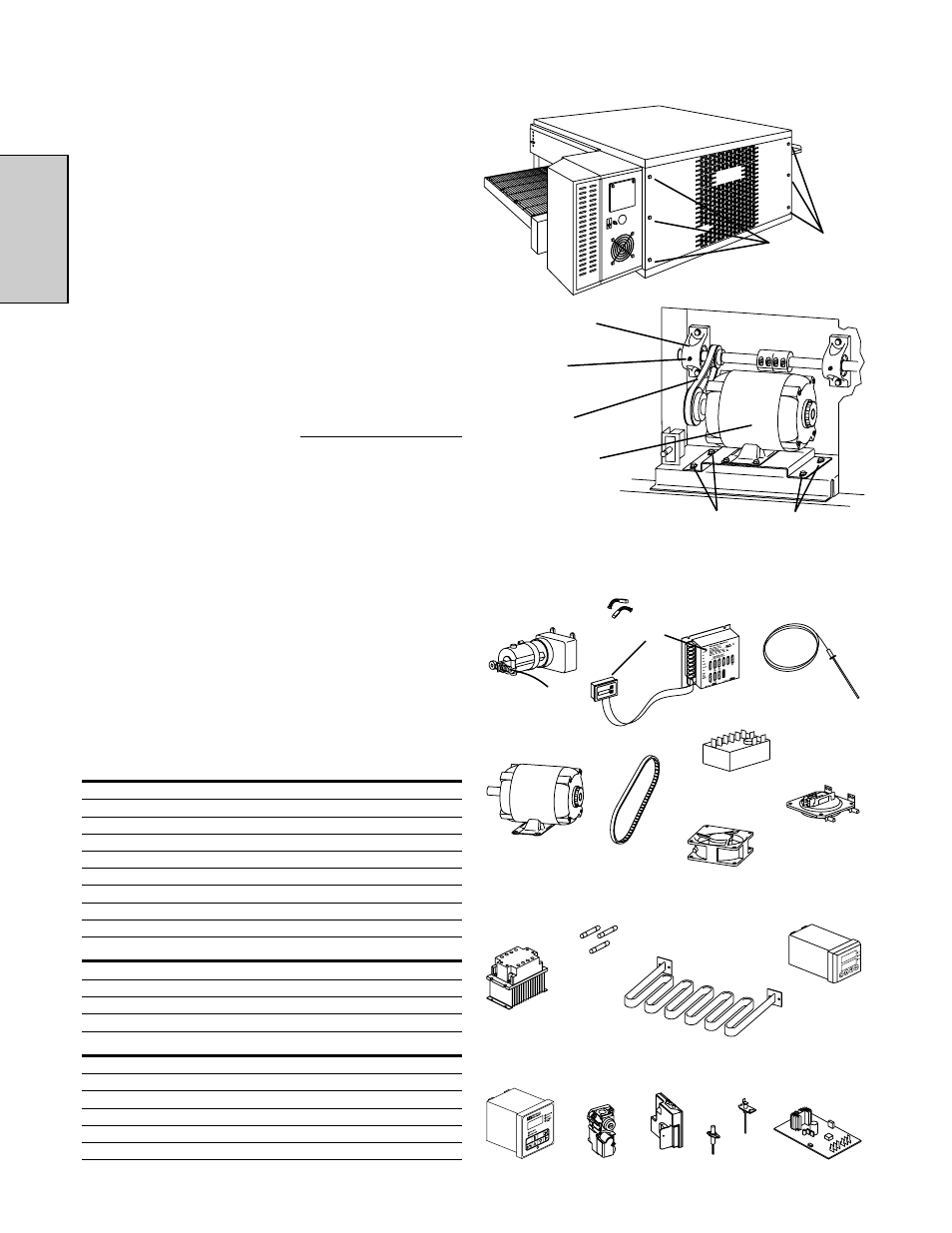

Fig. 4-12 - Key Spare Parts Kit

1

2

3

7

4

5

6

9

10

11

12

12

Remove six (6)

screws to remove

rear panel

Blower belt

Bearings

(2 total)

Blower motor

Loosen four (4) screws to adjust

motor position and belt tension

Figure 4-11 - Rear panel access

Grease fitting

(1 per

bearing)

8

V. KEY SPARE PARTS KIT - Available sepa-

rately. See Figure 4-12.

Item Qty. Part No.

Description

1

1

44695

Conveyor Drive Motor w/Pickup Assy.

2

2

30153

Drive Motor Brushes

3

1

37337

Kit, Conveyor Speed Controller

4

1

33985

Kit, Thermocouple

5

1

44687

Motor, Blower

6

1

44685

Belt, Blower

7

1

33983

High Limit Control Module, 230V

8

1

97525

Axial Cooling Fan, 230V

9

1

39530

Air Switch, 230V

ELECTRIC OVENS ONLY:

10

1

44585

Relay and Heat Sink Assembly

11

3

44701

Fuse, 60A

12

1

45281

Heating Element, 380V 8 kW

13

1

44783

Kit, Digital Temperature Controller

GAS OVENS ONLY:

14

1

36939

Kit, Digital Temperature Controller

15

1

45668

Gas Control Valve

16

1

45669

Ignition Module

17

1

45770

Ignitor

18

1

45771

Flame Probe

19

1

31651

Amplifier Board

13

14

15

16

17

Electric Ovens Only

Gas Ovens Only

E. Blower Belt

1. Remove the six screws shown in Figure 4-11. Then,

remove the rear panel from the oven.

2. Check the blower belt for the proper 6.4mm deflection

at the center, and for cracking or excessive wear. See

Figure 4-11. Overtightening the belt will cause prema-

ture bearing failure and possible vibrations. A loose

belt may also cause vibrations.

3. If necessary, adjust the tension of the belt by loosening

the four motor mounting bolts. Reposition the motor

as neccessary until the correct 6.4mm deflection is

reached, then tighten the bolts.

F. Lubricating the Blower Fan Bearings

1. Use a grease gun to lubricate the main blower fan

shaft bearings, shown in Figure 4-11.

When lubricating the bearings:

Use a high-quality NLGI #2, lithium soap grease with

petroleum oil, such as Middleby P/N 17110-0015.

Add the grease slowly until a small bead of grease

is present at the seals. AVOID OVERGREASING.

Excessive greasing may cause harm to the bearing.

2. Manually turn the blower shaft by pulling on the belt to

purge the grease. Wipe off any excess grease.

3. Replace the rear panel onto the oven.

18

19