8 abnormal image printing and defective roller – Muratec DIGITAL LASER F-114 User Manual

Page 81

Service Manual

Alignment & Troubleshooting

4-21

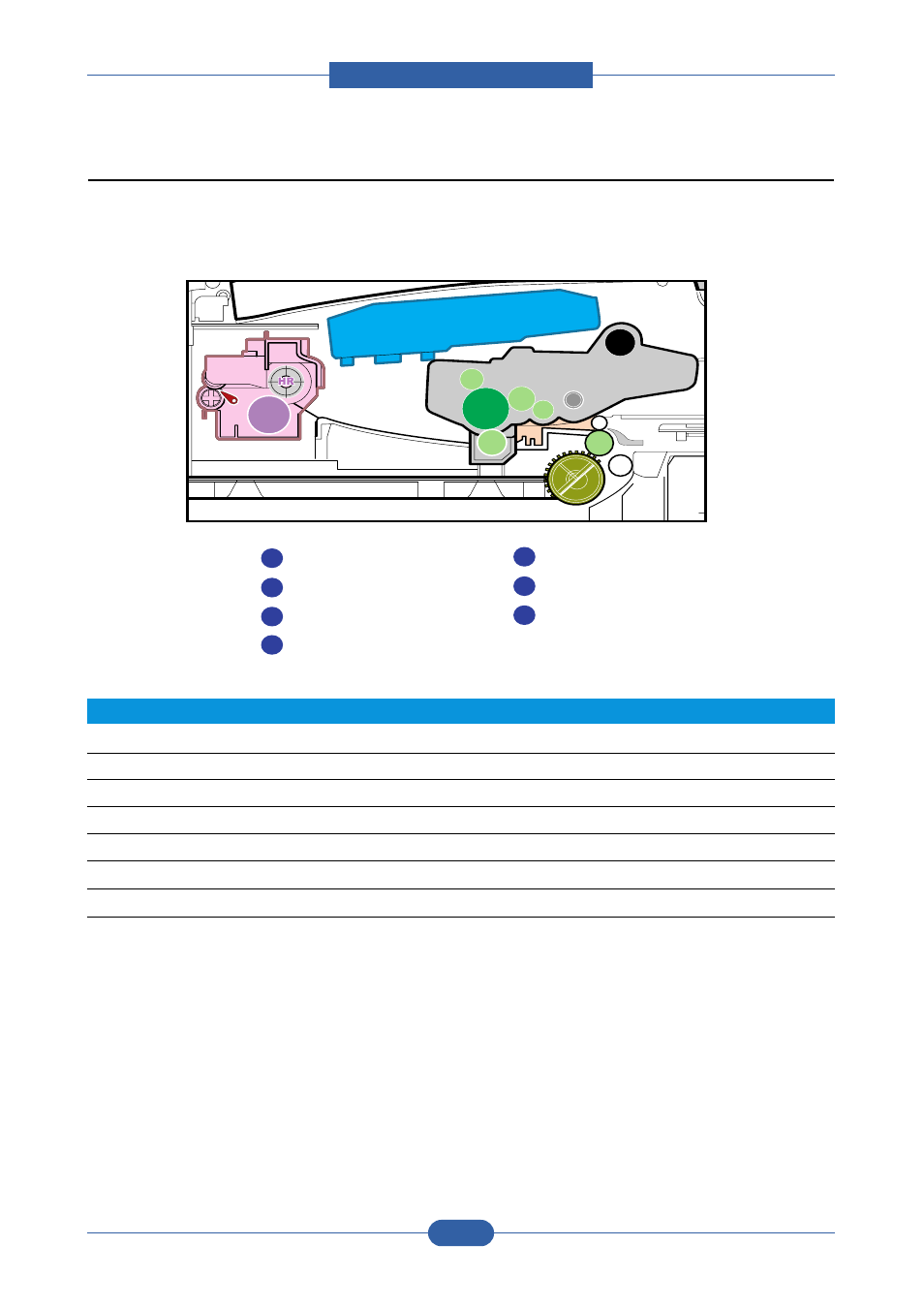

4.1.8 Abnormal Image Printing and Defective Roller

If a mark or other printing defect occurs at regular intervals down the page it may be caused by a damaged or

contaminated roller. Measure the repetition interval and refer to the table below to identify the roller concerned.

No

Roller

Abnormal image period

Kind of abnormal image

1

OPC Drum

75.5mm

White spot, Block spot

2

Charge Roller

37.7mm

Black spot

3

Supply Roller

37.0mm

Horizontal density band

4

Develop Roller

35.2mm

Horizontal density band

5

Transfer Roller

45.3mm

Black side contamination/transfer fault

6

Heat Roller

66.3mm

Black spot and fuser ghost

7

Pressure Roller

75.5mm

Black side contamination

PTL

P

IC

K

/R

PR

CR

DR

SR

TR

FR

OPC

L S U

Fuser

Toner Cartridge

MP Sensor

1

2

3

4

OPC Drum

Charge Roller

Supply Roller

Developing Roller

5

6

7

Transfer Roller

Heat Roller

Pressure Roller