Garland 200 User Manual

Page 89

Part # MCOSM06 Rev 1 (11/03/08)

Page 89

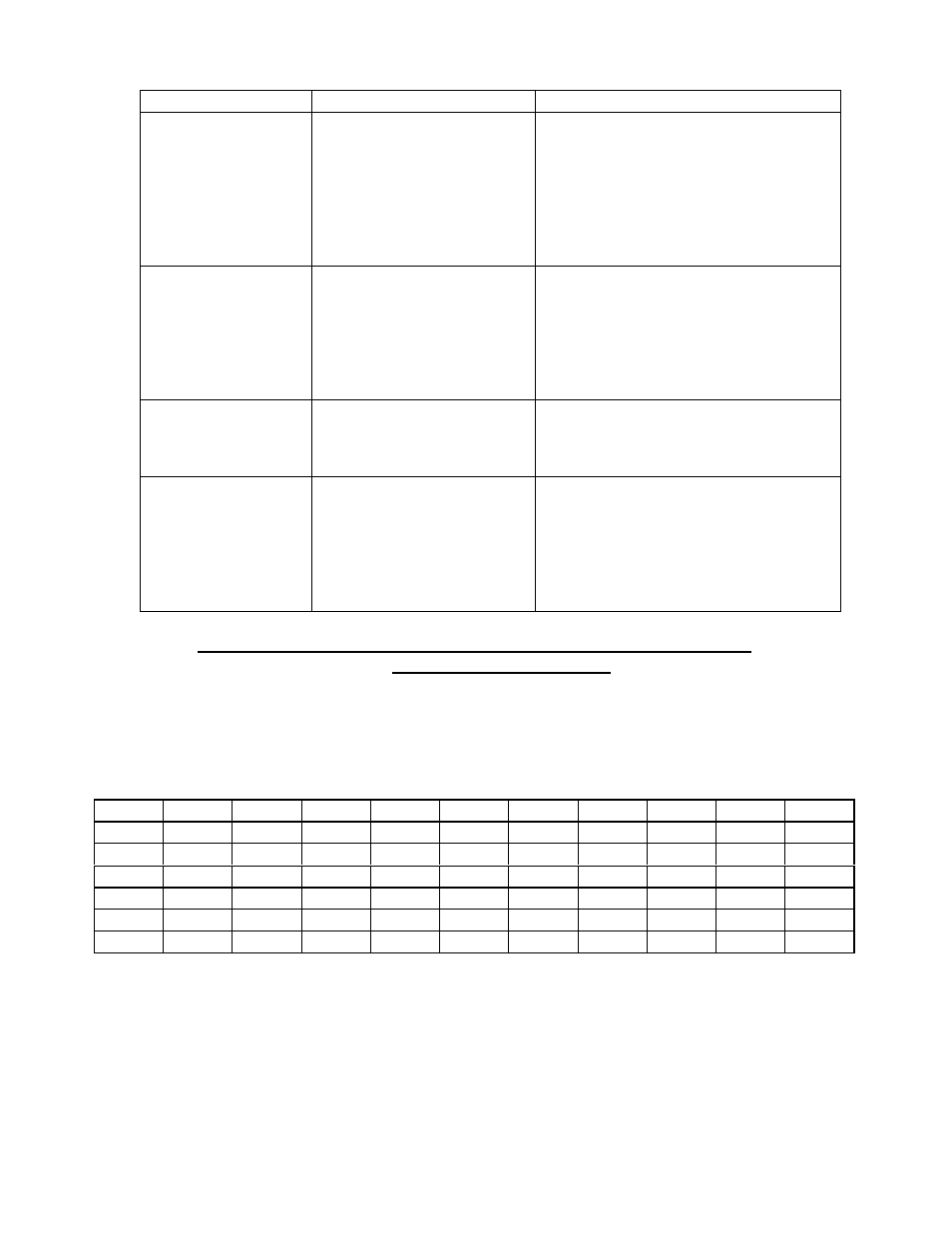

Problem

Possible Cause

Corrective Action

No display

A. No power to smart

board

B. No power to relay board

A. Check for 24VAC between pins 1

and 3 on smart board. If voltage

present check for 24VAC at pins 1

and 3 at relay board

B. Check for 24VAC into relay board

and 24VAC out of relay board

between pins 1 and 3 on relay

board

Fan runs for a period

of time, shuts down

then comes back on

after several minutes

A. motor has tripped on

internal thermal

overload

A. check for a minimum 6” clearance

at rear of unit to a wall or heat

source

B. Check air intake vents on back of

motor for obstructions

C. If problem persists and above have

been corrected replace motor assy

Timer slow counting

down

A. Timer is in hours / min

A. Refer to operations manual or

bulletin # B-19-2001 on how to

change from hour / min to min /

seconds

Temperature out of

calibration

A. 400 series controllers

B. 200 & 300 series

controllers

C. Potentiometer defective

A. Confirm oven cavity temp with

resistance chart. If out by more

than 20 Ohms replace probe

B. Calibration can be performed by

repositioning temperature dial.

C. Check for proper ‘sweep’ on

potentiometer. 0 to 10.25KOHMS

RESISTANCE vs. TEMPERATURE CHART FOR INTERNAL OVEN

TEMPERATURE SENSOR

The chart below will provide the Ohms at various temperatures. This will enable

you to determine if the temperature probe is operable.

The chart is degrees Fahrenheit.

TEMP

0°

10°

20°

30°

40°

50°

60°

70°

80°

90°

0°

932

953

974

995

1016

1038

1059

1080

1101

1122

100°

1143

1163

1184

1205

1226

1247

1267

1288

1309

1329

200°

1350

1370

1391

1411

1432

1452

1472

1493

1513

1533

300°

1553

1574

1594

1614

1634

1654

1674

1694

1714

1733

400°

1753

1773

1793

1813

1832

1852

1871

1981

1911

1930

500°

1949

1969

1988

2008

2027

2046

2065

2085

2104

2123

Page 3 of 9

1-800-427-6668 www.garland-group.com Fax: 1-800-361-7745