Garland 200 User Manual

Page 31

Part # MCOSM06 Rev 1 (11/03/08)

Page 31

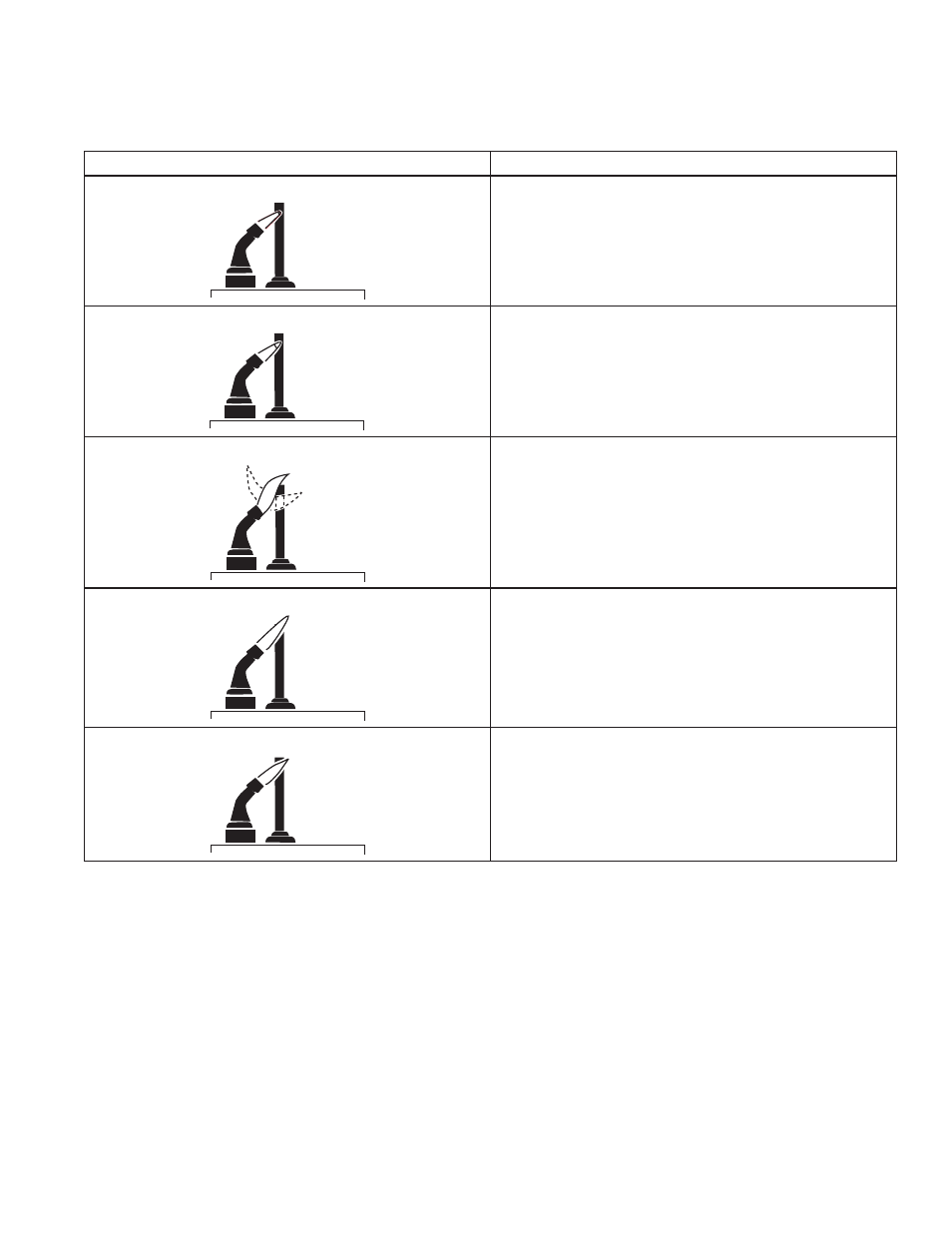

Examples Of Unsatisfactory Pilot Flames.

APPEARANCE

CAUSE

SMALL BLUE FLAME

Check for lack of gas from:

• Clogged orifice filter

• Clogged pilot filter

• Low gas supply pressure

• Pilot adjusted at the minimum

LAZY YELLOW FLAME

Check for lack of air from:

• Large orifice

• Dirty lint screen, if used

• Dirty primary air opening, if there is one

• Pilot adjusted at minimum

WAVING BLUE FLAME

Check for:

• Excessive draft at pilot locations

• Recirculating products of combustion

NOISY LIFTING BLOWING FLAME

Check for:

• High gas pressure

HARD SHARP FLAME

This flame is characteristic of manufactured gas

Check for:

• High gas pressure

• Orifice too small

Control Module Flame Sensor Circuit.

The control module provides AC power to theigniter/sensor

that the pilot burner flame rectifies to a direct current. If the

flame signal back the control module is not at least 1.0 μA

DC, the system will lockout. The output of the flame sensing

circuit cannot be checked directly, so check the flame sensing

circuit indirectly by checking the flame sensing current from

the igniter/sensor to the control module as follows:

1. Connect a meter (DC micrometer scale) in a series with

the flame signal ground wire (Burner Ground Terminal).

Disconnect the ground wire at the control module. Connect

the red (positive) lead of the meter to the free end of the

ground wire. Connect the black (negative) meter lead to the

quick-connect ground terminal on the control module.

2. Restart the system and read the meter. The flame sensor

currant must be at least 1.0 μA, and the reading must be

steady. If the reading is below the value designated or the

reading is unsteady, check the pilot flame and electrical

connection. Also, replace the igniter/sensor if the ceramic

insulator is cracked.