Workpiece inspection non-through & through cuts, Non-through & through cuts, Workpiece inspection – Grizzly G0493 User Manual

Page 40

-38-

Model g0493 (Mfg. since 7/10)

non-through &

through cuts

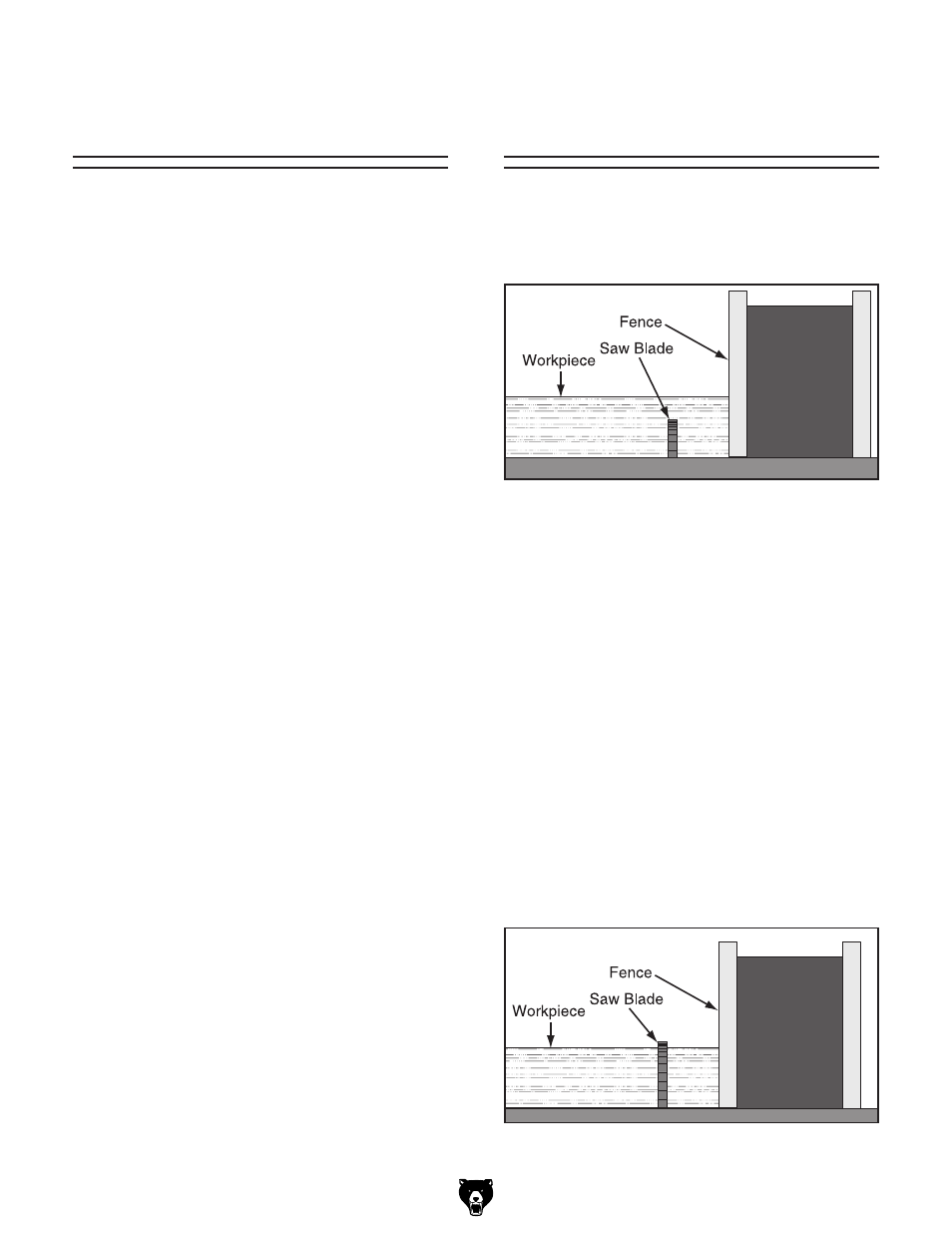

Examples of non-through cuts include dadoes

and rabbets. Non-through cuts have a higher risk

of injury from kickback because the blade guard

must be removed. However, the riving knife MUST

be installed because it still provides some protec-

tion. When making non-through cuts with a dado

blade, do not attempt to cut the full depth in one

pass. Instead, take multiple light passes to reduce

the load on the blade. A dado blade smaller than

10" will require removal of the riving knife, because

the riving knife will be higher than the blade.

non-through cuts

figure 64. example of a non-through cut.

A non-through cut is a sawing operation where

the blade does not protrude above the top face of

the wood stock, as shown in the

Figure below.

figure 65. example of a through cut (blade

guard not shown for illustrative clarity).

through cuts

A through cut is a sawing operation in which the

workpiece is completely sawn through, as shown

in the

Figure below. Examples of through cuts are

rip cuts, cross cuts, miter cuts, and beveled cuts.

The blade guard assembly MUST be used when

performing through cuts.

Workpiece

inspection

some workpieces are not safe to cut on this

machine or may need to be modified before they

can be safely cut.

before cutting, inspect all

workpieces for the following:

•

Material Type: This machine is intended for

cutting natural and man-made wood prod-

ucts, laminate covered wood products, and

some plastics. Cutting drywall or cementitious

backer board creates extremely fine dust and

may reduce the life of the motor bearings.

This machine is NOT designed to cut metal,

glass, stone, tile, etc.; cutting these materials

with a table saw greatly increases the risk of

injury and damage to the saw or blade.

•

Foreign Objects: Nails, staples, dirt, rocks

and other foreign objects are often embed-

ded in wood. While cutting, these objects

can become dislodged and hit the operator,

cause kickback, or break the blade, which

might then fly apart. Always visually inspect

your workpiece for these items. If they can’t

be removed, DO NOT cut the workpiece.

•

Large/Loose Knots: Loose knots can

become dislodged during the cutting opera-

tion. Large knots can cause kickback and

machine damage. Choose workpieces that

do not have large/loose knots or plan ahead

to avoid cutting through them.

•

Wet or “Green” Stock: Cutting wood with a

moisture content over 20% causes unneces-

sary wear on the blades, increases the risk of

kickback, and yields poor results.

•

Excessive Warping: Workpieces with exces-

sive cupping, bowing, or twisting are danger-

ous to cut because they are unstable and

may move unpredictably when being cut.

•

Minor Warping: Slightly cupped workpieces

can be safely supported with cupped side

facing the table or fence; however, work-

pieces supported on the bowed side will rock

during the cut, which could cause kickback.