Setup, Warning – Graco Inc. 237-296 User Manual

Page 5

308-425

5

Setup

General Information

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing.

NOTE: Always use Genuine Graco Parts and Acces-

sories, available from your Graco distributor. Refer to

the Product Data Sheet for the pump, Form No.

305–787. If you supply your own accessories, be sure

they are adequately sized and pressure rated for your

system.

Fig. 2 is only a guide for selecting and installing sys-

tem components and accessories. Contact your Graco

distributor for assistance in designing a system to suit

your particular needs.

Prepare the Operator

All persons who operate the equipment must be

trained in the safe, efficient operation of all system

components as well as the proper handling of all fluids.

All operators must thoroughly read all instruction

manuals, tags, and labels before operating the equip-

ment.

Prepare the Site

The pump requires 150 scfm (4.2 m#/min) of com-

pressed air while operating at 90 psi (6 bar, 0.6 MPa)

air pressure and 60 cycles per minute. Ensure that you

have an adequate compressed air supply.

Refer to Fig. 2. Bring a compressed air supply line (A)

from the air compressor to the pump location. Be sure

all air hoses (A) are properly sized and pressure-rated

for your system. Use only electrically conductive

hoses. The air hose should have a 3/4 npsm(m)

thread.

Install a bleed-type shutoff valve (B) in the air line to

isolate the air line components for servicing. Install an

air line moisture trap and drain valve (C) to help re-

move moisture from the compressed air supply.

Keep the site clear of any obstacles or debris that

could interfere with the operator’s movement.

Have a grounded, metal pail available for use when

flushing the system or draining the fluid filter.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below. Also read

the section

FIRE OR EXPLOSION HAZ-

ARD on page 4.

1.

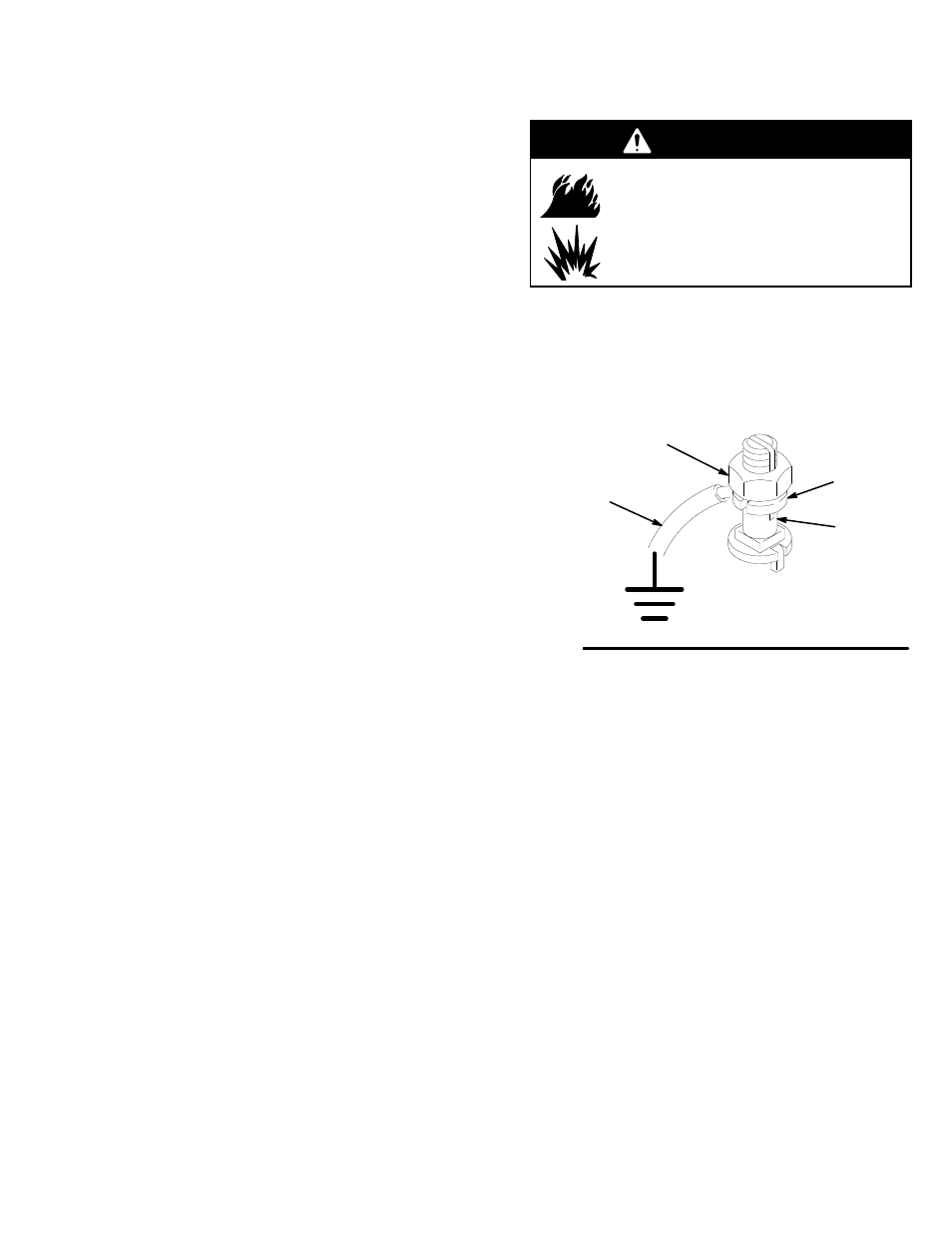

Pump: use the ground wire and clamp (supplied).

See Fig. 1. Loosen the grounding lug locknut (W)

and washer (X). Insert one end of the ground wire

(26) into the slot in lug (Z) and tighten the locknut

securely. Connect the other end of the wire to a

true earth ground.

Fig. 1

W

X

26

Z

0864

2.

Air and fluid hoses: use only electrically conductive

hoses.

3.

Air compressor: follow manufacturer’s recommen-

dations.

4.

Spray gun: ground through connection to a prop-

erly grounded fluid hose and pump.

5.

Fluid supply container: follow your local code.

6.

Object being sprayed: follow your local code.

7.

Solvent pails used when flushing: follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the

pail on a nonconductive surface, such as paper or

cardboard, which interrupts the grounding continu-

ity.

8.

To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the spray

gun firmly to the side of a grounded

metal pail,

then trigger the gun.