Checking v-belt, Tensioning v-belt – Grizzly Extreme Series Bandsaw G0514X User Manual

Page 61

G0514X/-X2/-X2B/-X3 (Mfg. Since 2/12)

-59-

checking v-Belt

to ensure optimum power transmission from the

motor to the blade, the v-belt must be in good

condition and operate under proper tension. the

belt should be checked for cracks, fraying, and

wear. Belt tension should be checked at least

every 3 months—more often if the bandsaw is

used daily.

To check the v-belt:

1. disConneCt BandsaW FroM poWer!

2. open the lower wheel cover.

3. note the condition of the v-belt. if the v-belt

is cracked, frayed, or glazed, replace it.

4. push the center of the v-belt. note the

amount of deflection (

figure 96). if deflection

is more than

3

⁄

4

", re-tension the v-belt.

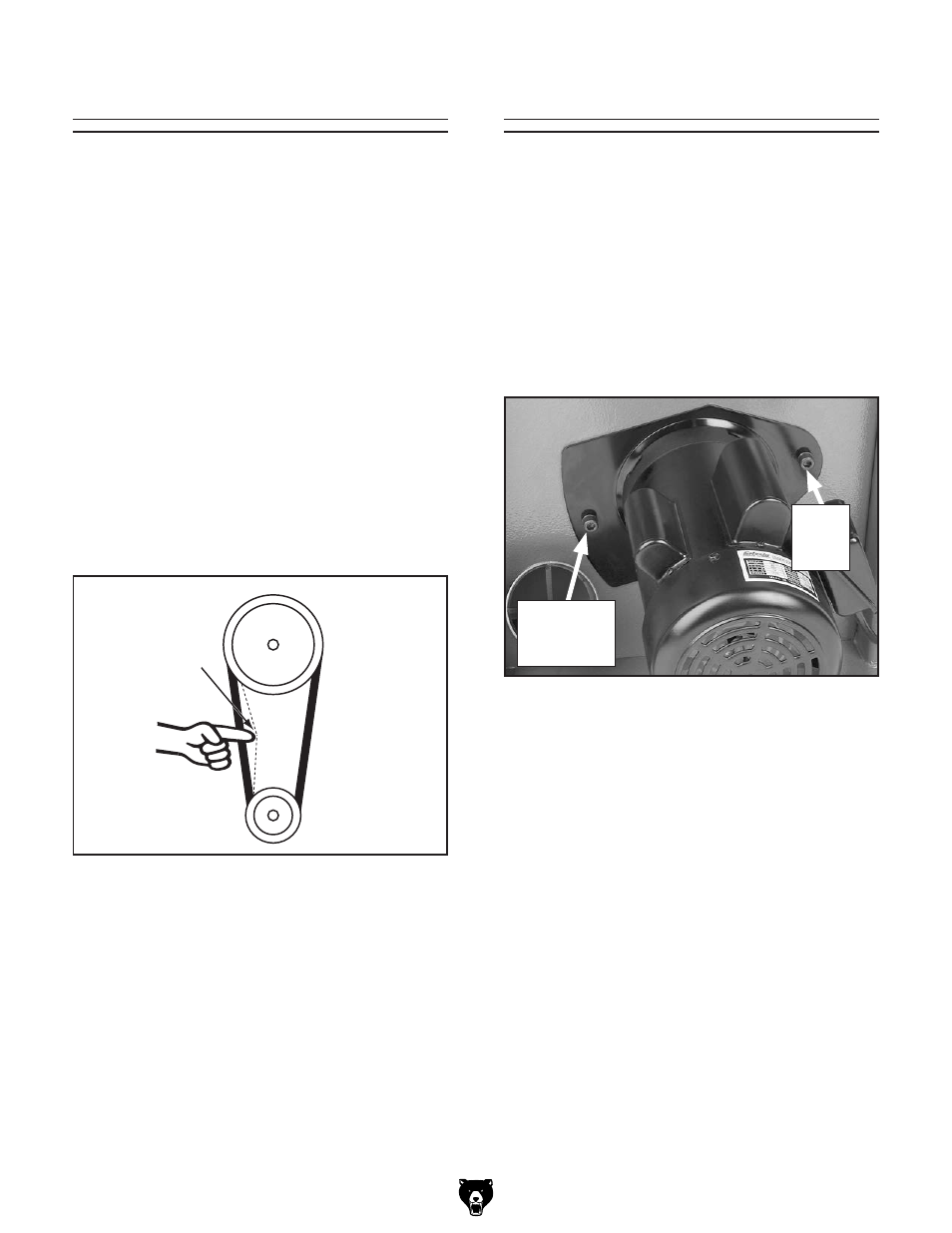

Tensioning v-Belt

Tools Needed:

Qty

hex Wrench 6mm ...............................................1

To tension the v-belt:

1. disConneCt BandsaW FroM poWer!

2. open the lower wheel cover.

3. loosen the motor mount screws shown in

figure 97.

4. rotate the motor down to tension the v-belt,

then tighten the motor adjustment screw.

5. push the center of the v-belt. if deflection

is approximately

3

⁄

4

" with moderate pressure

from your thumb or finger, then the tension

is correct. if the deflection is more than

3

⁄

4

",

repeat

Steps 3 & 4.

6. When the v-belt tension is correct, tighten

the motor hinge screw and close the lower

wheel cover.

Bandsaw

Wheel

Deflection

Motor

Wheel

figure 96. v-belt deflection.

figure 97. Motor mount screws.

Motor

adjustment

screw

Motor

hinge

screw