Clearance reduction methods – Greenheck Fan Canopy Type Kitchen Hoods 452413 User Manual

Page 8

8

Kitchen Hoods • Type I and Type II

Clearance Reduction Methods

Clearance reduction methods have been evaluated and

tested and are listed by UL (Underwriters Laboratory).

The method of test was derived from the UL 710 test

standard.

The hood may be installed with zero clearance to

combustible materials if constructed in the following

manner.

1. One inch (2.54 cm) thick layer of insulation of Owens

Corning® Type 475, Johns Manville Type 475, IIG®

MinWool-1200® Flexible Batt, or Knauf Insulation

Type EI 475.

2. Insulation must be held securely in place. Pins that

are welded or secured with an adhesive may be

used.

3. A backsplash panel must be attached to the wall

(insulated or uninsulated).

To comply with the UL listing, the cooking appliances

must be as follows:

• Maximum surface temperature is 700°F (371°C)

• Appliances are located at least 3 in. (7.62 cm) from

the rear wall

• Appliances are at least 40 in. (101.6 cm) below the

bottom front edge of the hood

The hood may be installed with 3 in. (7.62 cm) clearance

to limited combustible materials per NFPA 96 if

constructed in one of the following methods:

• 3 in. (7.62 cm) rear uninsulated stand-off

• 3 in. (7.62 cm) top enclosure panel system

• 3 in. (7.62 cm) end uninsulated stand-off

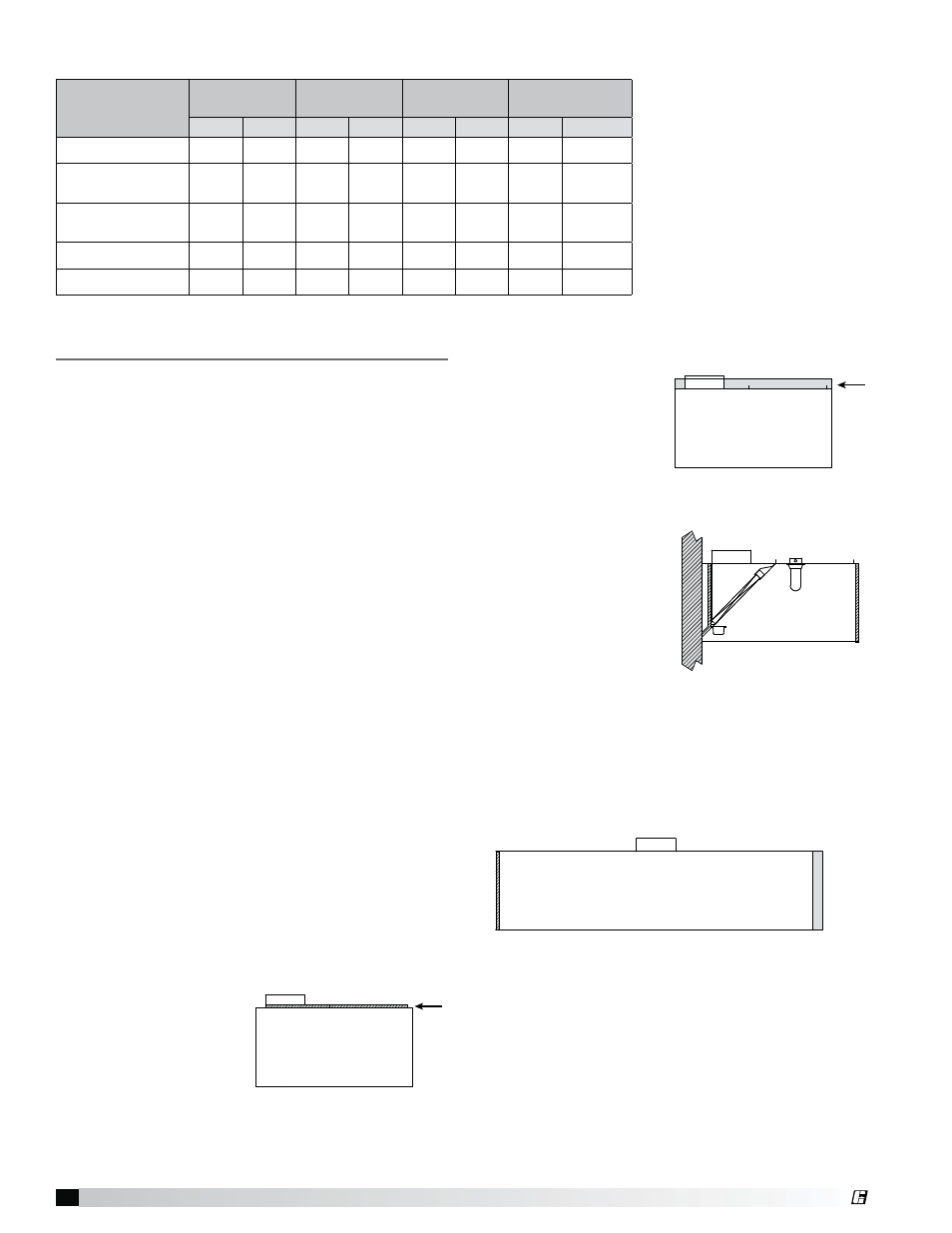

Top Clearance Reduction Options

One inch (2.54 cm) layer

of insulation installed

on top of the hood

(optional) meets zero

inch requirements for

clearance to combustible

surfaces as outlined under

the clearance reductions methods.

Three inches (7.62 cm)

insulated airspace

installed on top of hood

(optional) meets NFPA 96

requirements for clearance

to limited combustible

surfaces.

Back and Front Clearance Reduction Options

One inch (2.54 cm) layer

of insulation in 3 in. (7.62

cm) back stand-off meets

zero inch requirements for

clearance to combustible

surfaces as outlined under

the clearance reduction

methods.

Three inches (7.62 cm) uninsulated back stand-off

meets NFPA 96 requirements for clearance to limited

combustible surfaces.

One inch (2.54 cm) layer of insulation factory-installed

on the front of the hood (optional) meets zero inch

requirements for clearance to combustible surfaces.

End Clearance Reduction Options

One inch (2.54 cm) layer of insulation factory-installed

on the end of the hood (optional) meets zero inch

requirements for clearance to combustible surfaces

under the clearance reduction methods.

Three inches (7.62 cm) uninsulated airspace installed on

end of hood (optional). Meets NFPA 96 requirements for

clearance to limited combustible surfaces.

External Supply

Plenum Type

Weight

Width

Height

Length

per section

(lbs/ft)

(kg/m)

(in)

(mm)

(in)

(mm)

(ft)

(m)

Back Supply

35.0

52.09

6

152.4

Variable

Variable

3 to 16

.91 to 4.88

Air Curtain Supply

• 14 inch

9.5

14.14

14

355.6

10

254

3 to 16

.91 to 4.88

Air Curtain Supply

• 24 inch

12.5

18.60

24

609.6

10

254

3 to 16

.91 to 4.88

Variable Supply

16.0

23.81

12

304.8

18

457.20

3 to 16

.91 to 4.88

Horizontal Supply

14.0

20.83

12

304.8

18

457.20

3 to 16

.91 to 4.88

Weights and Dimensions

®