Filler panel installation, Installing the back supply plenum, Hood hanging height – Greenheck Fan Canopy Type Kitchen Hoods 452413 User Manual

Page 5

5

Kitchen Hoods • Type I and Type II

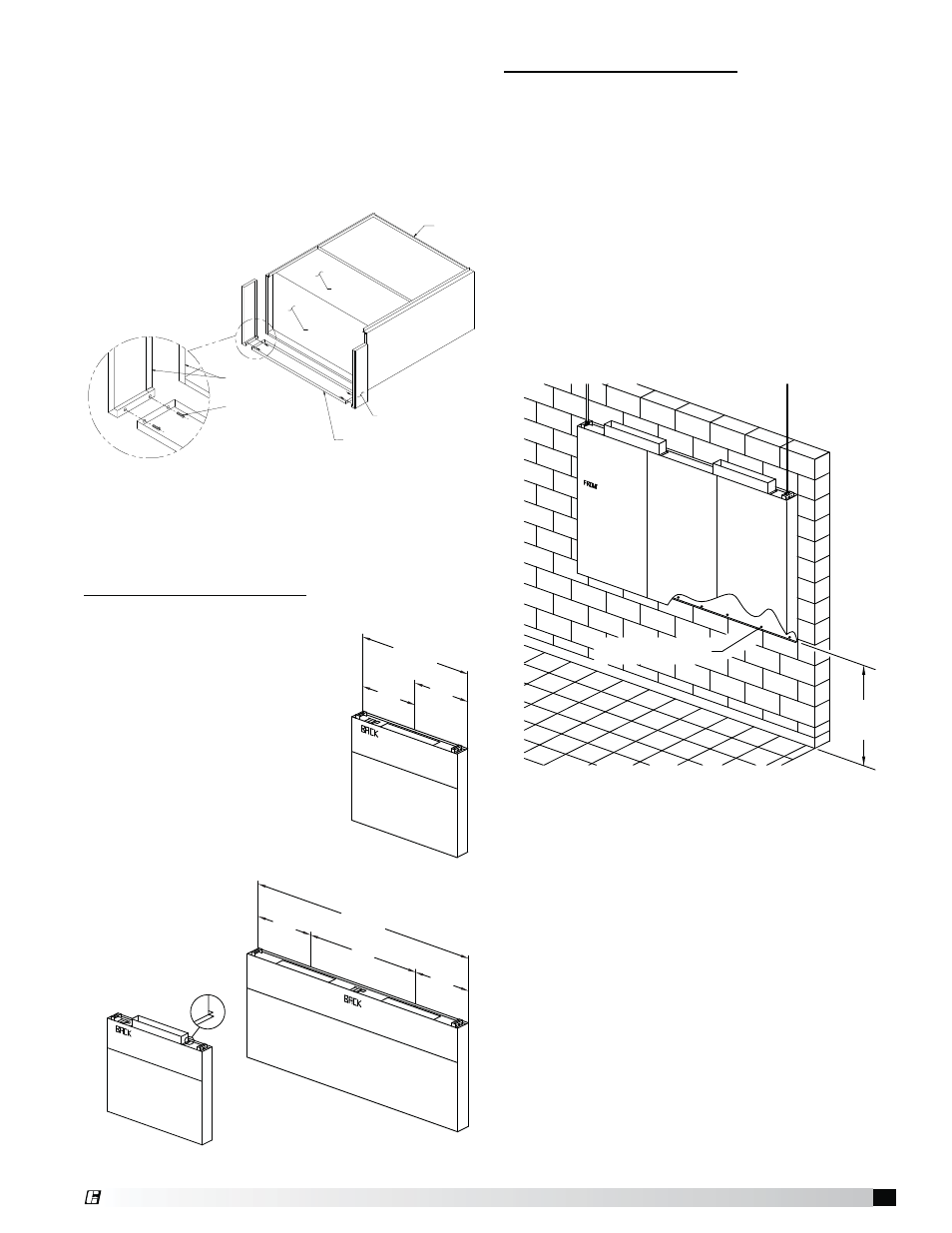

Filler Panel Installation

1. Uncrate the hood and lay it on the floor with

protective material between the hood and the floor.

2. Bolt the filler panels together with 5/16 in. bolts

provided in the hardware package.

3. Position the filler panels to the hood back, and tack-

weld them into place.

4. To allow for ease of cleaning, caulk the external

seams with NSF Approved silicone caulk (GE

SCS1009, or its equivalent). The caulk is not

provided.

Installing the Back Supply Plenum

Installing the Supply Duct Collar

1. Find the center of the back supply plenum.

2. If the back supply plenum is

to have one opening, cut the

opening such that it is centered

at L /2 from the plenum end.

(Fig. 1)

3. If the back supply plenum is to

have two openings, cut openings

such that they are centered

at L /4 from each end of the

plenum. (Fig. 2)

4. Place the duct collar(s) over the

opening(s), fastening with screws

or tack-welds

every 4 to 6 in.

(10.16 to 15.24

cm). (Fig. 3)

Hanging the Back Supply Plenum

5. Hang the back supply plenum from the ceiling.

• The back supply plenum needs to be mounted

31.25 in. (79.375 cm) above the finished floor. This

is measured from the lowest rear edge of the back

supply plenum to the finished floor.

•

Hang using threaded rod placed through the hanger

brackets.

6. Fasten the back supply to the wall, going through the

lower back supply wall.

•

These fasteners are to help maintain the location of

the back supply, and are not intended to hold the

weight of the back supply unit.

•

The fasteners should not interfere with the

removable air diffusers

Hood Hanging Height

The hood hanging height is critical. Hanging the hood at

the incorrect height may significantly reduce the ability

of the hood to function properly and may be in violation

of codes. The hood hanging height, typically 78 in.

(198.12 cm) above the finished floor, is given on the

UL label located on the end panel on the inside of the

hood. The hood must be hung level to operate properly.

The grease trough is pitched to drain into the grease

container.

HOOD

HOOD

HOOD

RIGHT FILLER PANEL

BOTTOM FILLER PANEL

TACK-WELDED TO

HOOD BACK

5/16 IN. X 3/4 IN. BOLTS

WITH WASHERS & NUTS

FASTENERS HOLDING THE

BACKSUPPLY TO THE WALL

31.25 INCH

CRITICAL

DIMENSION

L/2

L/2

L (MODULE LENGTH)

Fig. 1

L (MODULE LENGTH)

L/2

L/4

L/4

Fig. 2

Fig. 3

®