Electrical connections, Ductwork, Caution – Greenheck Fan Canopy Type Kitchen Hoods 452413 User Manual

Page 6: Double island style hoods, Installing u-channel strip, Continuous capture plenum hoods

6

Kitchen Hoods • Type I and Type II

Electrical Connections

Access for wiring the hood control panel (when

applicable) is provided by a junction box located on top

of the hood when the control panel is mounted in the

hood, or by the switch junction box when the control

panel is mounted in the fire protection cabinet. The

box is labeled “Control Voltage Wiring to Roof Top Fan

Package”. Use minimum 14 AWG copper wire. After

all the wiring is completed, install the light bulbs (light

bulbs not provided; standard light bulbs up to 100 watt

may be used).

Standard Greenheck light switches shipped on hoods

are rated for 15 amps and shall not have more than

14 lights connected to them. Higher amperage switches

are available upon special request.

Ductwork

Exhaust

As specified in NFPA 96, Ch. 7.5 (latest edition), exhaust

duct systems must be constructed in the following

manner:

Materials: Ducts shall be constructed of and supported

by carbon steel not less than 1.37 mm (0.054 in.) (No.

16 MSG) in thickness, or stainless steel not less than

1.09 mm (0.043 in.) (No. 18 MSG) in thickness.

Installation: All seams, joints, penetrations, and duct to

hood collar connections shall have a liquid-tight external

weld. If you have an automatic fire damper, please refer

to that manual for installation instructions now.

Supply

Supply ductwork (where applicable) should be

connected to the hood in a manner approved by the

local code authorities.

For proper installation of duct collars when they are

shipped unattached, see page 11.

CAUTION

For multiple hood systems that have more than 14

lights total (incandescent or fluorescent), the hood

lights must be wired to multiple circuits. Each circuit

must have less than 14 lights total.

NOTE

For hoods with fire dampers in the exhaust and

supply duct collars, an access panel for cleaning and

inspection shall be provided in the duct. This panel

shall be as close to the hood as possible but should

not exceed 18 in. (45.72 cm).

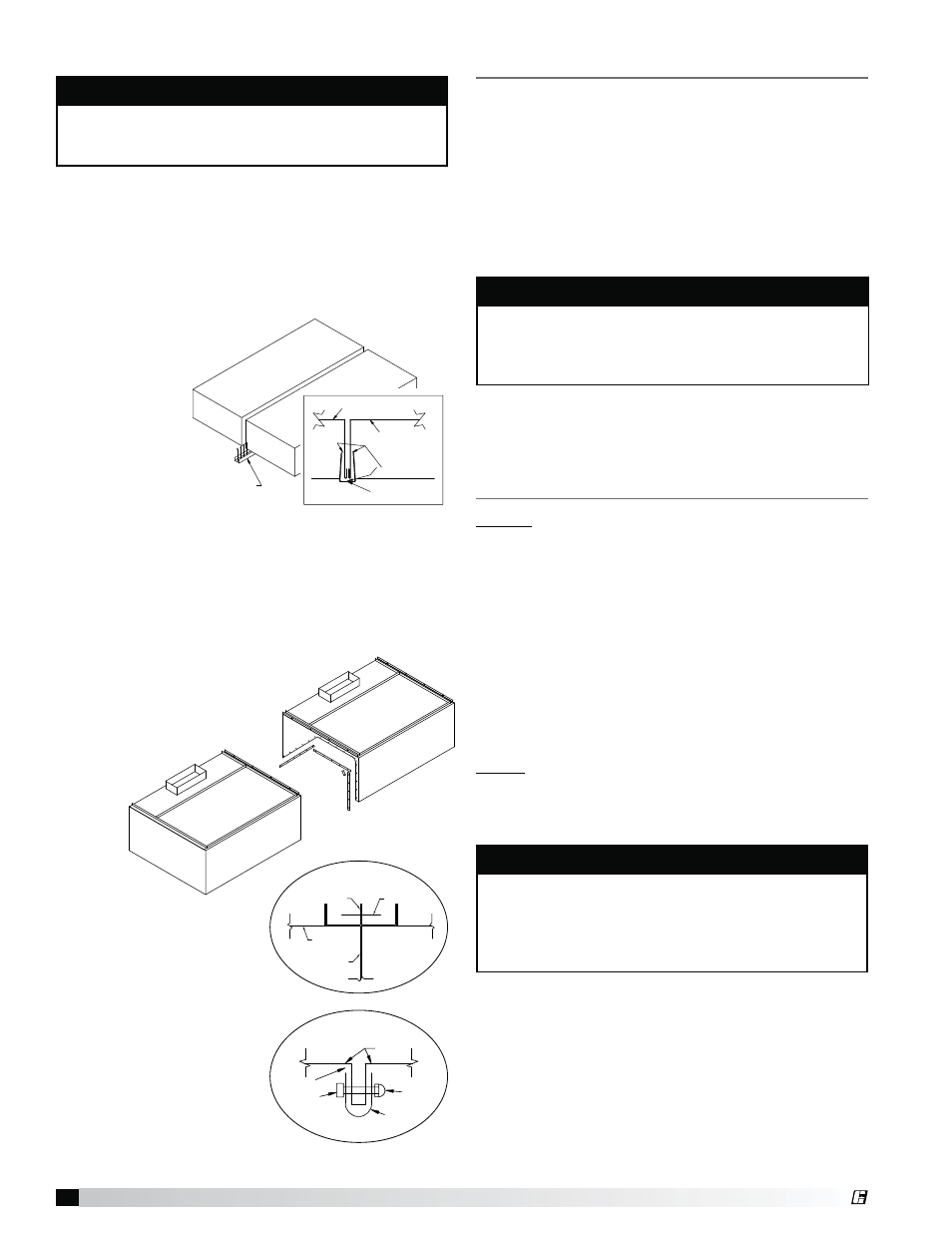

Double Island Style Hoods

A double island hood is created by installing two

wall style hoods back to back. Use the installation

procedure described on page 4 for single island hoods;

install and level both hoods. After leveling, secure the

hoods together by tack-welding and/or bolting the rear

mounting brackets together.

Installing U-Channel Strip

1. After the hood

is hung in

position and

leveled, apply

caulk to the

inside edge

of the double

island clip.

2. Position and

install the clip

by tapping

into position along clip (friction fit).

3. Caulk edges to seal out grease and allow for ease

of cleaning. Caulk with NSF Approved silicone caulk

(GE SCS1009 or its equivalent). The caulk is not

provided.

Continuous Capture Plenum Hoods

Remove the support angles provided

for support during shipping on

the open end panels. Use the

installation procedure

described on page 4

for single island

hoods;

install

and level

both

hoods.

After

leveling, secure

the hoods together by tack-

welding and/or bolting the

angles that are located at

the top of the hoods along

its width (Fig. 4).

Next, fasten the hoods

together at its inside plenum

profile using u-clips and

bolts (Fig. 5). Caulk this joint

with NSF Approved silicone

caulk (GE SCS1009 or its

equivalent). The caulk is not

provided.

After the hood is installed, remove all protective plastic.

NOTE

Before hanging the hoods, please verify the hood

marks to make sure the correct hood is hung on the

correct side.

HOOD FRONT

ITEM-1B

DOUBLE ISLAND CLIP

ITEM-1A

HOOD-1B

DOUBLE ISLAND CLIP

SILICONE CAULK

(GE SCS1009)

HOOD-1A

Fig. 4

BOLT OR WELD

HOOD TOP

HOOD END

SUPPORT ANGLES

CAULK

BOLT

U-CLIP

HOOD

ACORN

NUT

Fig. 5

2. RAISE

AND SU

3. FASTE

4. FASTE

5. CAULK

& CAP

1. REMO

HOOD FRONT

HOOD FRONT

REMOVE

SUPPORT

ANGLES ON

THE OPEN

END PANEL

®