Installing duct collars, Exhaust air balancing baffles (eabb), Back view of the hood – Greenheck Fan Canopy Type Kitchen Hoods 452413 User Manual

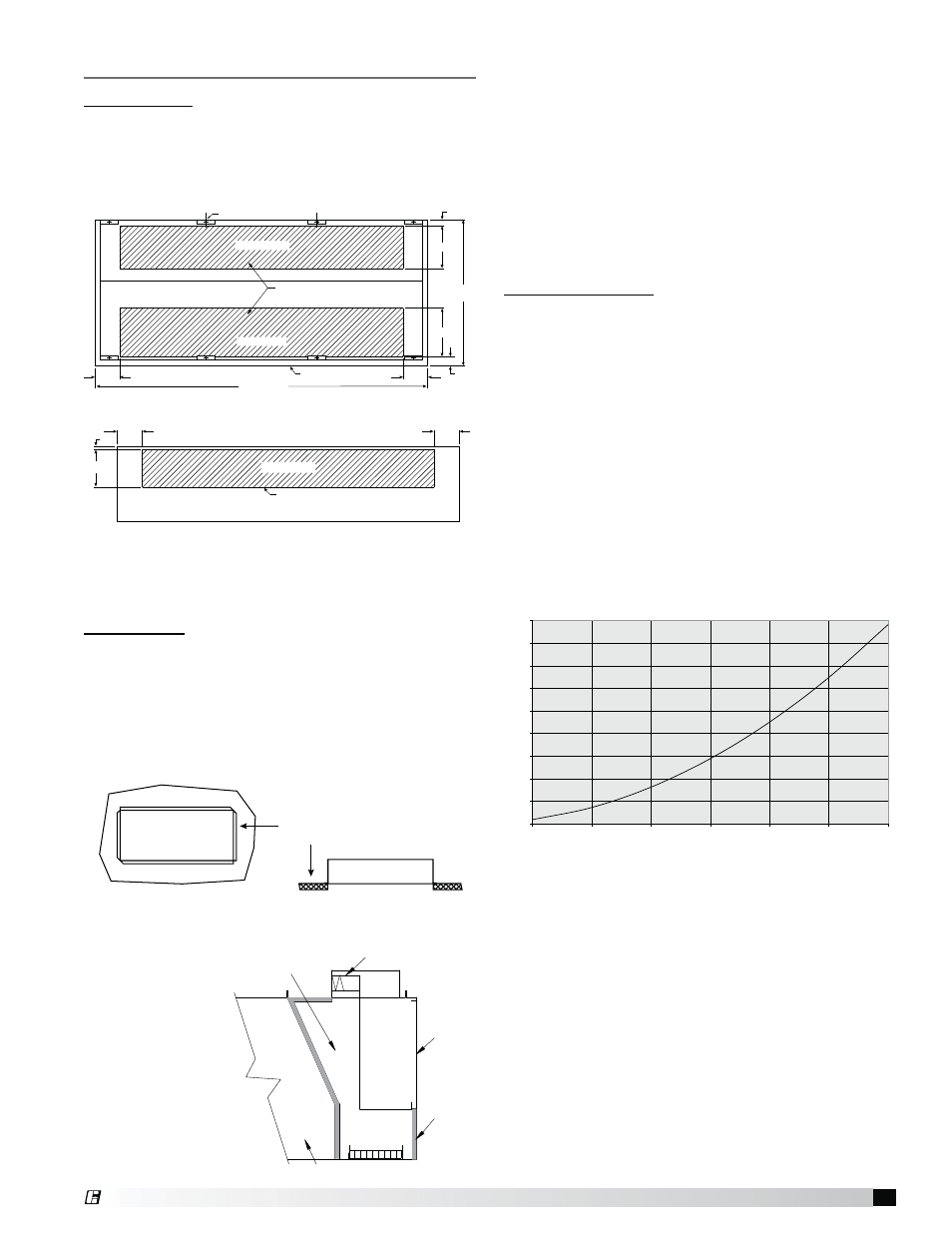

Page 11: Top view of the hood

11

Kitchen Hoods • Type I and Type II

Duct cut out area

Hood Top

Exhaust Plenum

8 in.

8 in.

1 in.

12 in.

Back View of the Hood

Hanger Bracket

Exhaust Plenum

Duct cut out area

Supply Plenum

Hood Length

Hood

Width

Front of hood

8 in.

3 in.

3 in.

16 in.

14 in.

8 in.

Top View of the Hood

Maximum Increase in Static Pressure for Exhaust Air Balancing Baffle

(Fully Closed)

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

500

1000

1500

2000

2500

3000

3500

Duct Velocity FPM

In

cr

ease i

n

Co

ll

a

r St

ai

tc

Pr

essur

e

Installing Duct Collars

Exhaust Collars

1. The exhaust duct connection needs to be located

within 48 in. (121.92 cm) from the center of the hood

length to the center of the duct connection and within

shaded area as shown.

2. The exhaust duct connection is to be a continuous

liquid-tight weld. Weld with a non-ferrous filler wire,

such as silicon bronze or stainless steel filler wire.

Protect all stainless steel areas from weld splatter.

Supply Collars

1. The supply duct connection needs to be located

within the shaded Supply Plenum area as in the

drawing above.

2. The supply duct connection is tack-welded at 1 to

2 inch (2.54 to 5.08 cm) intervals or sheet metal

screws at 3 to 6 in. (7.62 to 15.24 cm) spacing to

the hood.

3. For hoods that are insulated, the edges of the

insulation must be taped after the hole is cut. (The

insulation tape

is provided by

others).

4. On combination

hoods, make

certain the

fire damper

is located

over the

internal supply

chamber.

Supply Duct

Connection

Supply duct connection to be tack

welded with 1 to 2 inch tack or

sheet metal screws at 3 to 6 inch

spacing to hood.

Internal Supply

Chamber

Supply Fire Damper

Insulated

Supply

Plenum

Exhaust Capture

Hood

Exhaust Air Balancing Baffles (EABB)

This is a guide to assist in determining if multiple

hoods on one fan can be balanced to have equal static

pressure. For multiple hoods on one fan to achieve their

designed exhaust flow, all of the hoods must have equal

static pressure at their designed exhaust flow.

The laws of physics force the static pressure for each

branch of a duct system on one fan to always be equal.

This will happen by the flow rate increasing in low static

branches and decreasing in high static branches until

the static pressure is equal in all branches.

Checking for Balance

Every hood with exhaust air balancing baffles (EABB)

has a range for its static pressure. The low static

pressure number (when EABB is open) in this range is

given by the standard calculation for hood static and is

printed on the CAPS submittal page for that hood. The

high static pressure number (when EABB is closed) in

this range can be found by calculating the maximum

potential increase of static and adding that value to the

low static pressure number.

High static pressure number = low static pressure

number + maximum increase

The maximum potential increase in static is given in the

graph, or can be calculated from the following formula:

Maximum Increase = 0.00000036 x (Duct velocity)

2

®