Unit start-up, Vibration, Direction of fan wheel rotation – Greenheck Fan HEAT RECOVERY UNIT WITH EVAPORATIVE COOLING HRE-20 User Manual

Page 33: Fan rpm

33

Vibration

Excessive vibration may be experienced during initial start-up . Left unchecked, excessive vibration can cause

a multitude of problems, including structural and/or component failure . The most common sources of vibration

are listed below .

Many of these conditions can be discovered by careful observation . Refer

to the Troubleshooting section of this manual for corrective actions . If

observation cannot locate the source of vibration, a qualified technician using

vibration analysis equipment should be consulted . If the problem is wheel

unbalance, in-place balancing can be done .

Generally, fan vibration and noise is transmitted to other parts of the building

by the ductwork . To eliminate this undesirable effect, the use of heavy canvas

connectors is recommended .

1 . Wheel Unbalance

2 . Drive Pulley Misalignment

3 . Incorrect Belt Tension

4 . Bearing Misalignment

5 . Mechanical Looseness

6 . Faulty Belts

7 . Drive Component Unbalance

8 . Poor Inlet/Outlet Conditions

9 . Foundation Stiffness

UNIT START-UP

R

o

ta

tio

n

R

o

ta

tio

n

Rotation

Rotation

Backward Inclined

Forward Curved

Airflow

Airflow

Rotation Direction

R

o

ta

tio

n

R

o

ta

tio

n

Rotation

Rotation

Backward Inclined

Forward Curved

Airflow

Airflow

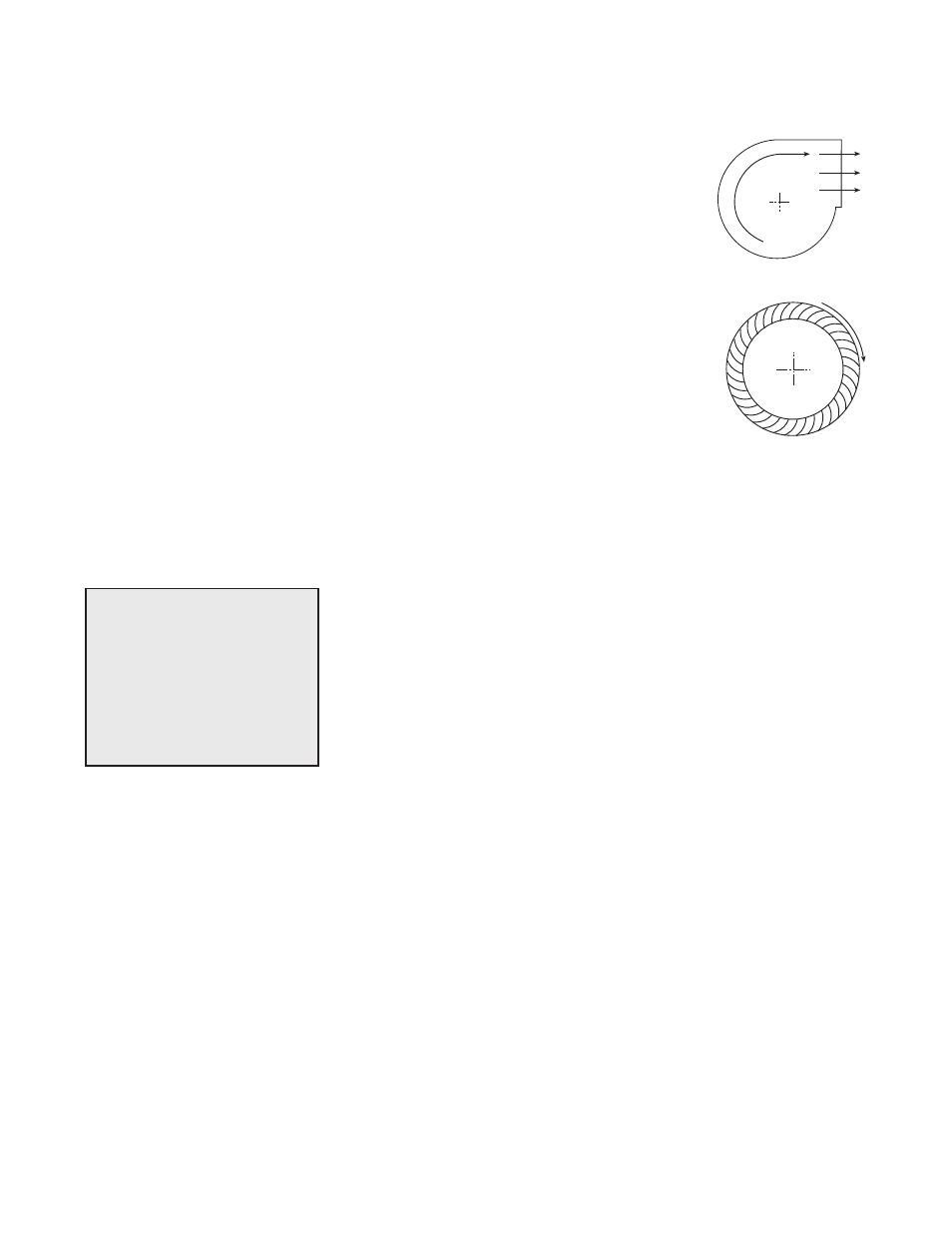

Direction of Fan Wheel Rotation

Blower access is labeled on unit . Check for proper wheel rotation by momentarily

energizing the fan . Rotation is determined by viewing the wheel from the drive

side and should match the rotation decal affixed to the fan housing (see Rotation

Direction figures) . If the wheel is rotating the wrong way, direction can be reversed

by interchanging any two of the three electrical leads .

Check for unusual noise,

vibration, or overheating of bearings . Refer to the Troubleshooting section of this

manual if a problem develops .

Fan RPM

Supply fan and exhaust fan will have an adjustable motor pulley (on 15 HP and

below) preset at the factory to the customer specified RPM . Fan speed can be

increased or decreased by adjusting the pitch diameter of the motor pulley . Multi-

groove variable pitch pulleys must be adjusted an equal number of turns open or

closed . Any increase in fan speed represents a substantial increase in load on the

motor . Always check the motor amperage reading and compare it to the amperage

rating shown on the motor nameplate when changing fan RPM . All access doors

must be installed except the control center door . Do not operate units with access

doors open or without proper ductwork in place as the fan motors will overload.