Troubleshooting for evaporative module, Symptom solution – Greenheck Fan HEAT RECOVERY UNIT WITH EVAPORATIVE COOLING HRE-20 User Manual

Page 15

15

Symptom Solution

Leaving Air

Entering Air

45

°

15

°

Insufficient water

volume or recirculation

pump not operating

Irregular water

distribution on cooling

media

Scale and mineral

deposit formation on

face of media

Excessive water

discharge into drain

Water Carry-Over

Poor performance

after cooling pad

replacement

Inadequate cooling

A . Check water level in base pan . The

level should be at 1 inch .

B . Check the pump filter at the inlet .

Clean the filter if clogged or dirty .

C . If pump is not operating, check

wiring for loose connections and

proper voltage .

D . Clogged or worn out pump .

E . Clogged header .

F . Water flow adjustment device

Water distribution header, orifices or media partially blocked or plugged .

Remove evaporative cooler from unit .

Disassemble and clean distribution header, orifices and media .

A . Increase bleed rate .

B . Increase water flow rate . Media is self-cleaning with flow rate of

1

1

/

2

to 2

gpm per square foot of media top area . Generally this flow rate prevents

dissolved solvents from collecting on the media . To prevent further

trouble, flush and clean the system more frequently .

C . Check water flow across the face of the media . Irregular water distribution

must be corrected (see above)

D . If this condition persists, chemicals may need to be added . Water pH

should be maintained between 6 and 8 .

A . Irregular water distribution on face of media (see above) .

B . Average face velocity exceeds 550 fpm . Decrease fan rpm and airflow .

C . Localized face velocities exceeding 550 fpm . Air filters or media face area

is partially blocked . Clean or replace air filters and media .

D . Check the overflow for blockage .

A . Irregular water distribution over face of media (see above) .

B . Check for uniform airflow .

C . Check outside wet-bulb temperature . High wet-bulb temperatures can

decrease performance .

D . Check water flow rate over media . Flow rate should be

1

1

/

2

to 2 gpm per

square foot of media top area .

A . Check the water bleed off rate and make sure that it is not excessive .

B . Check water level in base pan . The level should be at 1 inch .

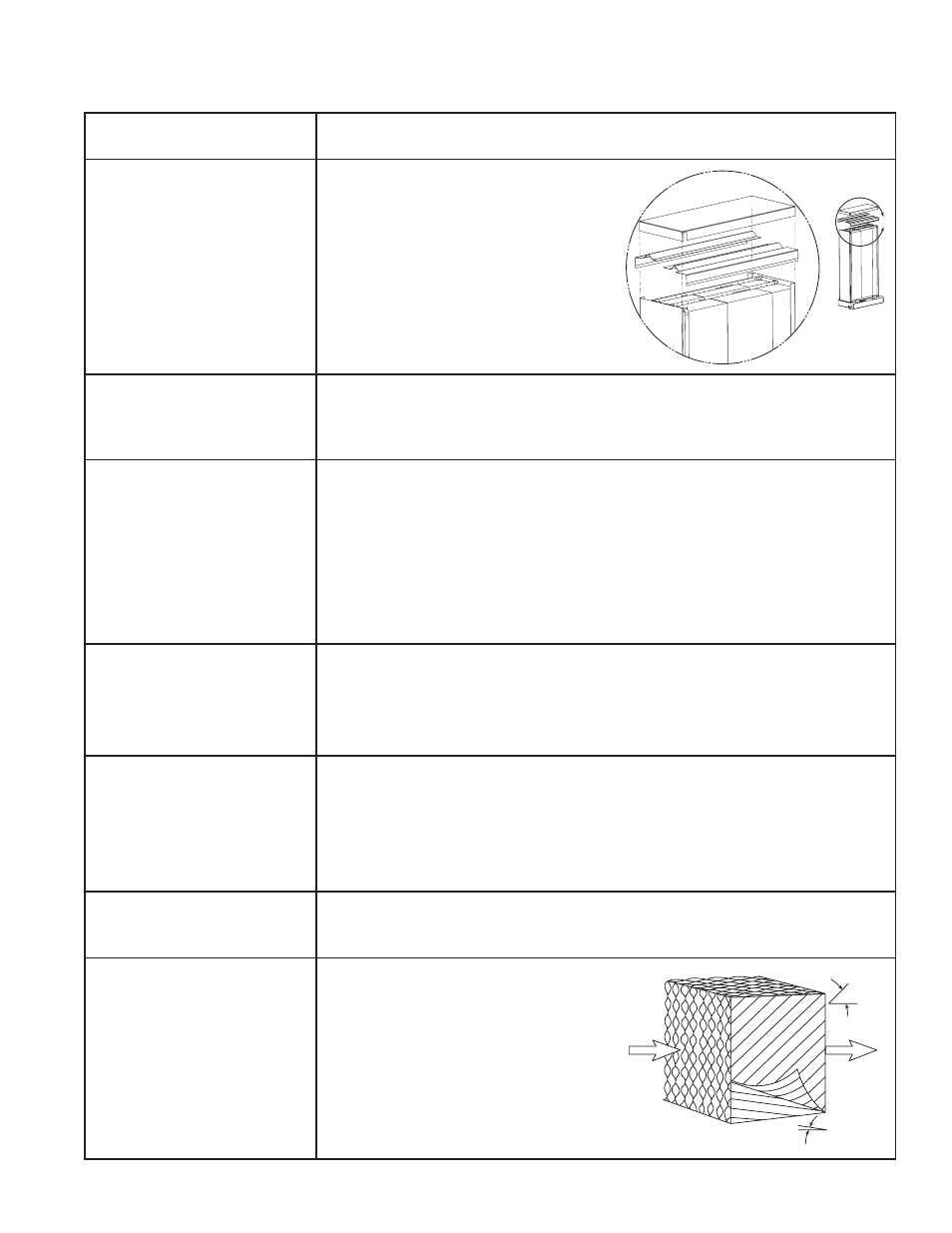

Pad installed backwards . To get the

performance from the cooling pads,

they must be installed properly . The

pads are manufactured with 15/45

degree flute angles . The pads must

always be installed with the steeper

flute angle sloping down toward the

entering air side . See figure on right .

TROUBLESHOOTING FOR EVAPORATIVE MODULE

C

Header

Detail