GE E4H Series User Manual

Page 26

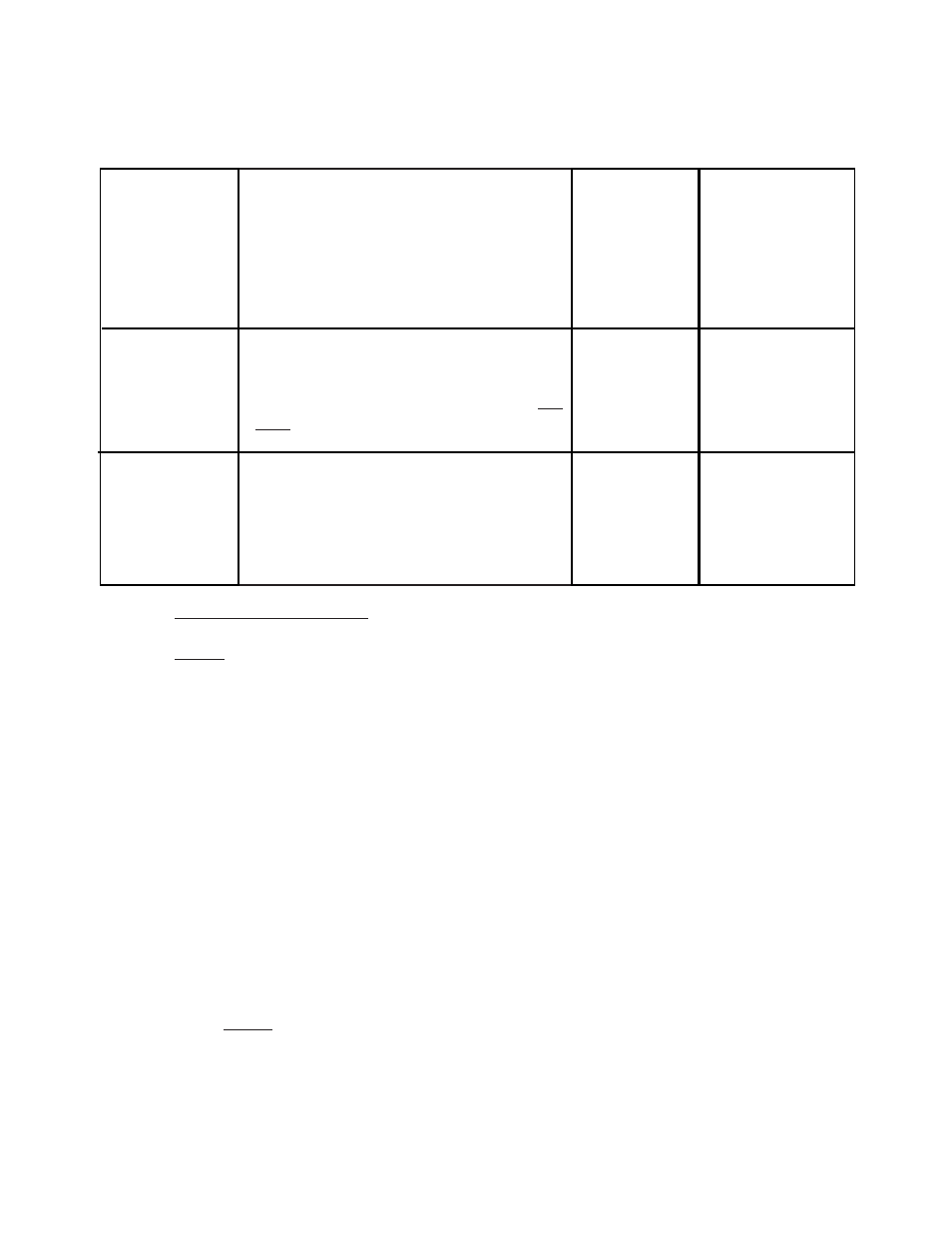

Table 4.4

Dry Chemical Cleaners

CLEANING PROCEDURE

STEPS

1.

With the RO machine running, open the Clean-In-Place (CIP) permeate valve. After this

valve has been opened, close the permeate service valve. Permeate water will flow into

the CIP tank. Allow the water to run through the CIP tank and the CIP tank drain valve

for a few minutes to ensure the tank is rinsed thoroughly. After a minute or so, close the

CIP tank drain valve. The CIP tank should begin to fill with RO permeate. When the CIP

tank has filled to the indicated full line, turn the ON/OFF switch on the RO machine to the

OFF position.

2.

While the machine is OFF, open the CIP inlet valve. Divert the permeate and concentrate

streams to the cleaning container for recirculation. Ensure that the pre-filter is clean. A

CIP pump (supplied with DLX models only) is recommended to supply feed pressure into

the machine.

3.

To circulate the cleaning solution through the machine with suction, remove the CIP plug.

Use a non-collapsible suction hose or pipe to feed the machine.

NOTE: Do not allow the machine pump to operate without concentrate flow. If pump

prime is lost while cleaning on suction, positive inlet pressure is required to

reprime. No air should be sucked into the inlet line during suction cleaning.

20

Description

Dry acid-surfactant for cleaning TLC, PA

and CA membrane elements.

High pH alkaline cleaner for PA membrane

elements. Recommended for situations

where microbial fouling is a problem. DO

NOT use on CA membrane elements.

Cleaner intended to deal with sulfate

or iron precipitation fouling. Recommended

for CA and PA membrane elements.

Cleaner

Osmo AD-20

Osmo AK-110

Osmo ET-70

Part Number

1155420

1155421

1155422

1155423

1155416

1155417

1155418

1155419

1155424

1155425

1155426

1155427

Quantity

8 x 4 lb. pkgs/case

45 lb. pail

100 lb. key

300 lb. drum

8 x 4 lb. pkgs/case

45 lb. pail

100 lb. key

300 lb. drum

8 x 4 lb. pkgs/case

45 lb. pail

100 lb. key

300 lb. drum