Grizzly G0459P User Manual

Page 36

-34-

Model G0459/G0459P (Mfg. 7/11+)

5. raise the table until the gauge blocks just

touch the bottom of the sanding drum.

Note: A good way to know when they are

touching is to rock the sanding drum back

and forth while raising the table until you hear

or feel contact with the gauge blocks.

6. lower the table one full turn of the crank han-

dle. Wait until the chain starts moving before

starting to count the crank handle rotation.

7. starting at one end, place a 0.002" feeler

gauge between the sanding drum and the

gauge block. (the feeler gauge should slide

with moderate resistance, without forcing the

drum to roll.)

8. repeat Step 7 at the other end of the drum.

—if the difference between the two sides is

0.002" or less, skip to the subsection that

covers how to adjust the sanding drum

perpendicular to the feed direction

on this

page.

— if the difference between the two sides is

more than 0.002", then one side must be

adjusted to within 0.002" of the other (with

the ultimate goal of making them dead

even). Continue to the next step.

to adjust the sanding drum perpendicular to

the feed direction:

1.

disConneCt poWer to the sander!

2.

First measure the distance between the out-

side of the drum and the inside of the dust

scoop (

figure 33). the distances should be

within

1

⁄

8

" of each other at each end of the

drum.

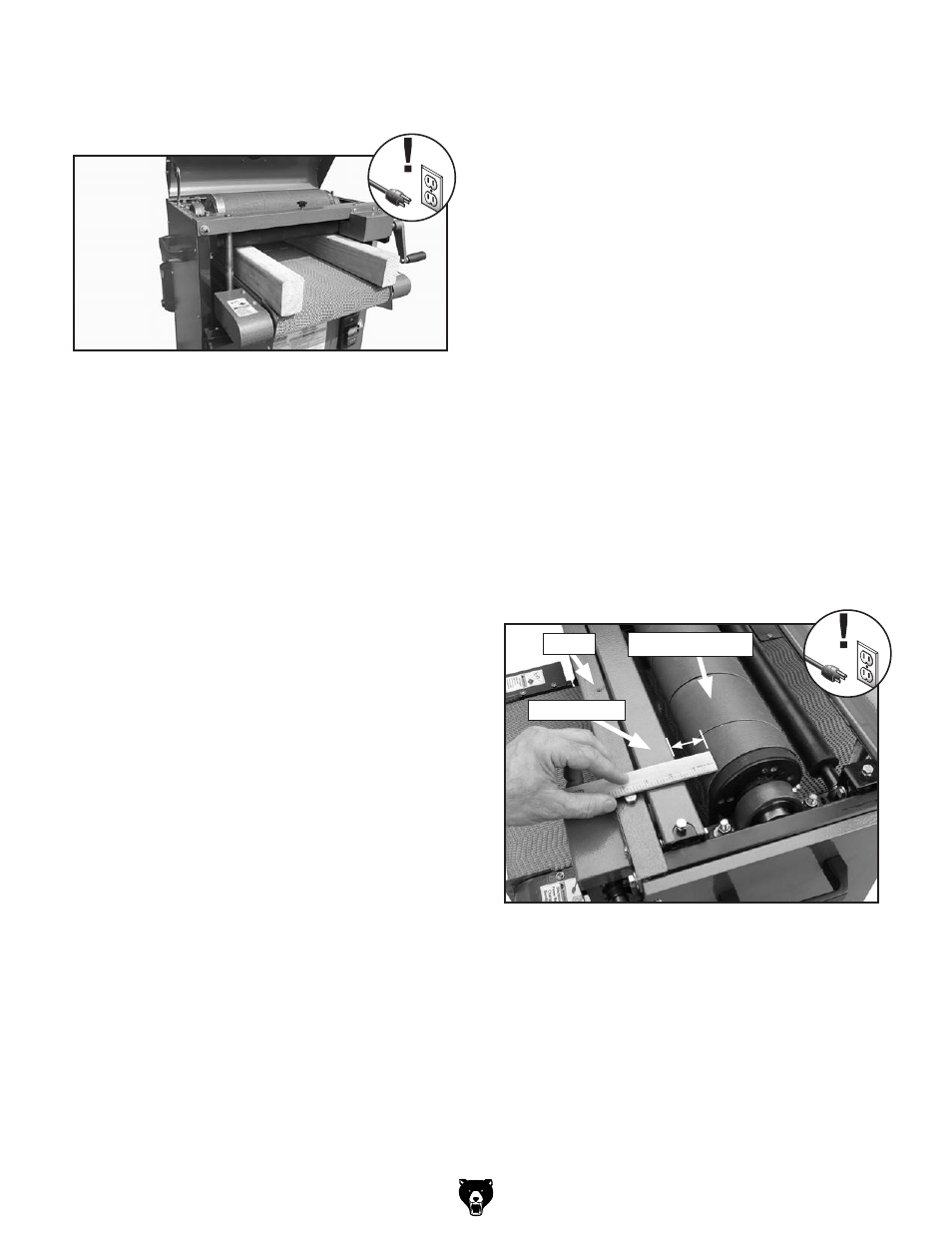

figure 33. Measuring distance between drum

and dust scoop.

3.

if the measurements are not within

1

⁄

8

", the

drum can be moved by loosening the lock

nuts on the pillow block bearings and moving

one end of the drum forward or backward as

necessary in the slotted holes.

Note: After you have adjusted the drum, do

not forget to tighten the lock nuts and recheck

the alignment by repeating

Steps 1–3.

dust scoop

sanding drum

brace

4. place the gauge blocks on the conveyor table

and position them under the pressure rollers,

as shown in

figure 32.

figure 32. gauge blocks positioned under

pressure rollers and sanding drum.

to adjust the pillow block bearings:

1. loosen the lock nuts (see figure 31) on

one of the pillow block bearings that requires

adjustment.

2. rotate the setscrews

1

⁄

8

of a turn

clockwise to

raise the pillow block bearings (see

figure

31).

Note: Turn all setscrew sets an equal

amount.

3. tighten the lock nuts and recheck the align-

ment using the gauge blocks, repeating

Steps

1–8 from the previous subsection. tightening

the lock nuts will pull the drum downward

slightly. be sure to adjust to compensate

for this movement.

Do not over tighten the

lock nuts. the pillow block bearings can

break if over tightened.