Anti-kickback fingers – Grizzly G0633/G0634 User Manual

Page 54

-52-

G0633/G0634 Jointer/Planer Combo Machine

2. Adjust the tension screws counterclockwise

so that they are five to seven turns below the

top of the head casting.

— If the workpiece slips when you feed it, turn

the screws

1

⁄

2

to 1 turn counterclockwise to

increase spring tension.

— If the workpiece is abruptly grabbed when

initially fed into the planer, turn the screws

1

⁄

2

to 1 turn clockwise to decrease spring

tension.

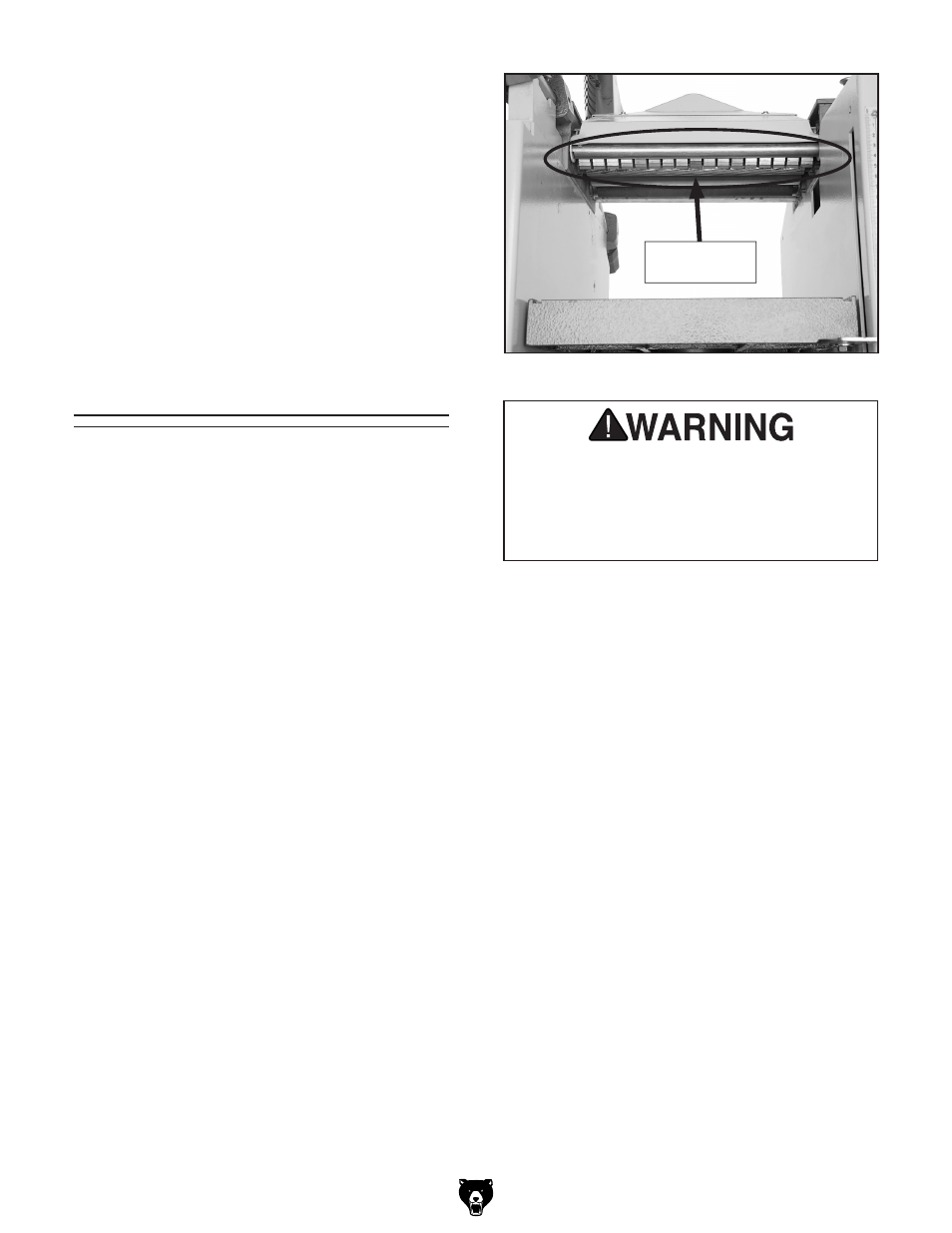

Anti-Kickback Fingers

The Model G6333/G0634 provides an anti-kick-

back system as a safety feature. The anti-kick-

back fingers hang from a rod suspended across

the cutterhead casting. The anti-kickback fingers

should be inspected regularly.

Check the fingers (

Figure 79) to ensure that they

swing freely and easily.

If the fingers do not swing

freely and easily, clean them with a wood resin

solvent.

Proper operation of the anti-kickback fin-

gers is essential for the safe operation of

this machine. Failure to ensure that they

are working properly could result in serious

operator injury.

Do not apply oil or other lubricants to the anti-

kickback fingers. Oil or grease will attract dust,

restricting the free movement of the fingers.

Figure 79. Anti-kickback fingers.

Anti-Kickback

Fingers