Cutting (jointer and planer) – Grizzly G0633/G0634 User Manual

Page 40

-38-

G0633/G0634 Jointer/Planer Combo Machine

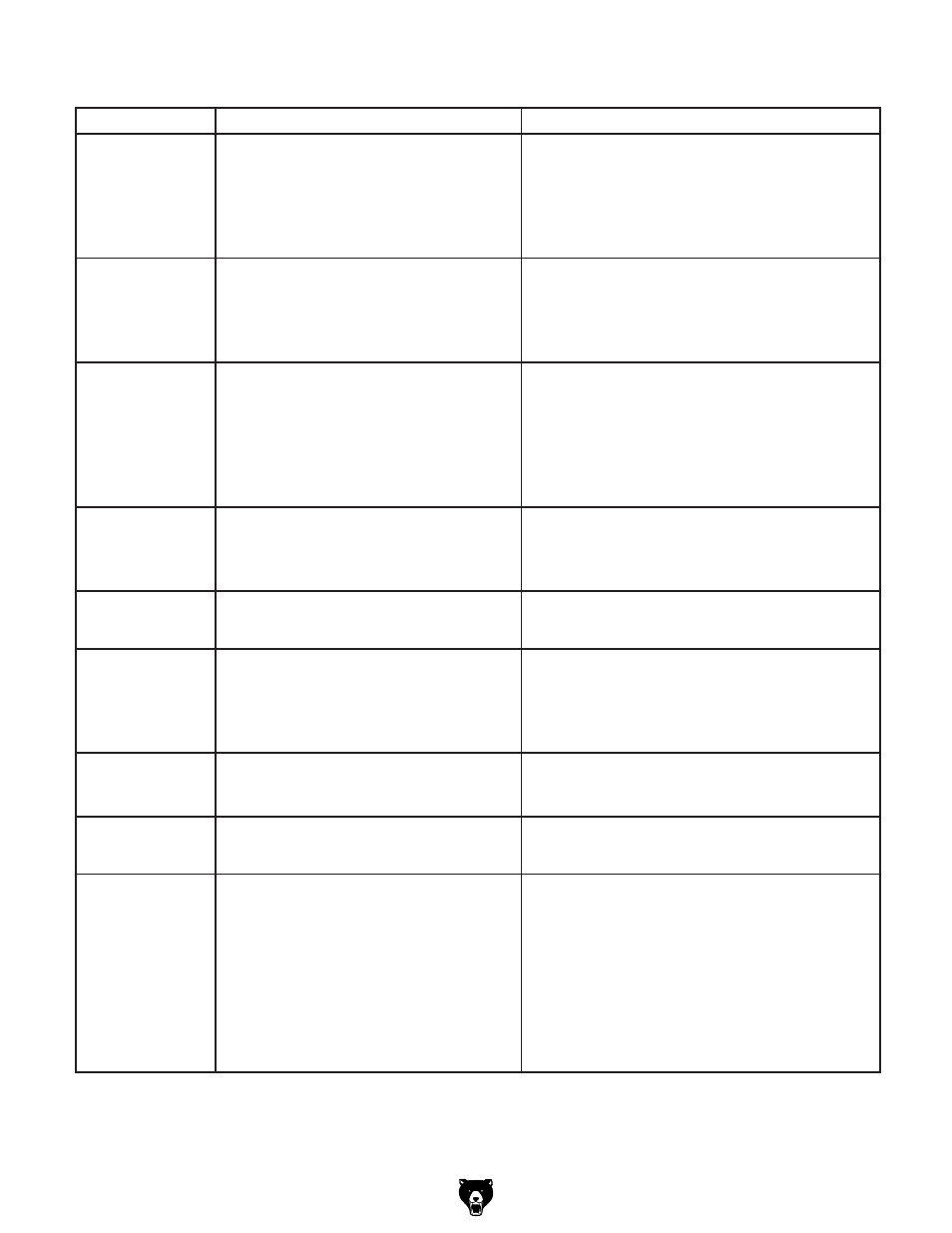

Symptom

Possible Cause

Possible Solution

Excessive

snipe

(gouge in the end

of the board that is

uneven with the rest

of the cut).

1. Outfeed table is set too low.

2. Operator pushing down on trailing end of

workpiece.

3. Workpiece is not supported as it leaves the

planer.

1. Align outfeed table with cutterhead knife at top dead

center (

Page 18).

2. Reduce/eliminate downward pressure on trailing end

of workpiece.

3. Support the workpiece as it leaves the outfeed end

of the planer.

Workpiece stops/

slows in the middle

of the cut.

1. Taking too heavy of a cut.

2. Table not parallel with head casting.

3. Pitch and glue build up on planer compo-

nents.

1. Take a lighter cut.

2. Adjust the table so it is parallel to the head casting

(

Page 50).

3. Clean the internal cutterhead components with a

pitch/resin dissolving solvent.

Chipping (consistent

pattern).

1. Knots or conflicting grain direction in wood.

2. Nicked or chipped knife or carbide insert.

3. Taking too deep of a cut.

1. Inspect workpiece for knots and grain direction; only

use clean stock.

2. Replace the knife or rotate/replace affected insert

(

Page 43 or 45).

3. Take a smaller depth of cut. (Always reduce cutting

depth when surface planing or working with hard

woods.)

Fuzzy grain.

1. Wood may have high moisture content or

surface wetness.

2. Dull knives or inserts.

1. Check moisture content and allow to dry if moisture

is too high.

2. Rotate/replace the knives or inserts (

Page 43 or

45).

Long lines or ridges

that run along the

length of the board

1. Nicked or chipped knives or inserts(s).

1. Replace or offset knives or rotate/replace inserts

(

Page 43 or 45).

Uneven knife or

insert marks, wavy

surface, or chatter

marks across the

face of the board.

1. Knives not adjusted at even heights in the

cutterhead.

2. Carbide inserts not installed evenly.

3. Worn cutterhead bearings.

1. Adjust the knives so they are set up evenly in the

cutterhead (

Page 43).

2. Make sure carbide inserts do not have debris under

them; make sure inserts are torqued down evenly.

3. Replace cutterhead bearings.

Glossy

surface.

(Planer)

1. Knives or carbide inserts are dull.

2. Cutting depth too shallow.

1. Rotate/replace the knives or inserts (

Page 43 or

45).

2. Increase the depth of cut.

Chip Marks (incon-

sistent

pattern).

(Planer)

1. Chips aren't being properly expelled from

the cutterhead.

1. Use a dust collection system

Board edge is con-

cave or convex after

jointing. (Jointer)

1. Board not held with even pressure on infeed

and outfeed table during cut.

2. Board started too uneven.

3. Board has excessive bow or twist along its

length.

4. Insufficient number of passes.

1. Hold board with even pressure as it moves over the

cutterhead.

2. Take partial cuts to remove the extreme high spots

before doing a full pass.

3. Surface plane one face so there is a good surface to

position against the fence.

4. It may take 3 to 5 passes to achieve a perfect edge,

depending on starting condition of board and depth

of cut.

Cutting (Jointer and Planer)