Frymaster FOOTPRINT 8195991 User Manual

Page 13

2-4

2. Single unit fryers must be stabilized by installing restraining chains on fryers equipped with

casters or anchor straps on fryers equipped with legs. Follow the instructions in the accessory

pack to install the chains or straps.

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable,

tip over, and cause injury. The appliance area must be kept free and clear of

combustible material at all times.

3. Level fryers equipped with legs by screwing out the legs approximately 1 inch then adjusting

them so that the fryer is level and at the proper height in the exhaust hood. Frymaster

recommends that the minimum distance from the flue outlet to the bottom edge of the hood be 24

in. (600 mm) when the appliance consumes more than 120,000 BTU per hour. NOTE: There

are no built-in leveling devices on fryers equipped with casters. The floor where the fryer is to

be installed must be level.

4. Test the fryer electrical system:

a. Plug the fryer electrical cord(s) into a grounded electrical receptacle.

b. Place the power switch in the ON position.

• For fryers equipped with solid-state (analog) controls, verify that the power and heat

lights are lit.

• For fryers having computer or digital displays, verify that the display indicates CYCL.

c. Place the fryer power switch in the OFF position. Verify that the power and heat lights are

out, or that the display is blank.

5. Refer to the data plate on the inside of the fryer door to determine if the fryer burner is

configured for the proper type of gas before connecting the fryer quick-disconnect device or

piping from the gas supply line.

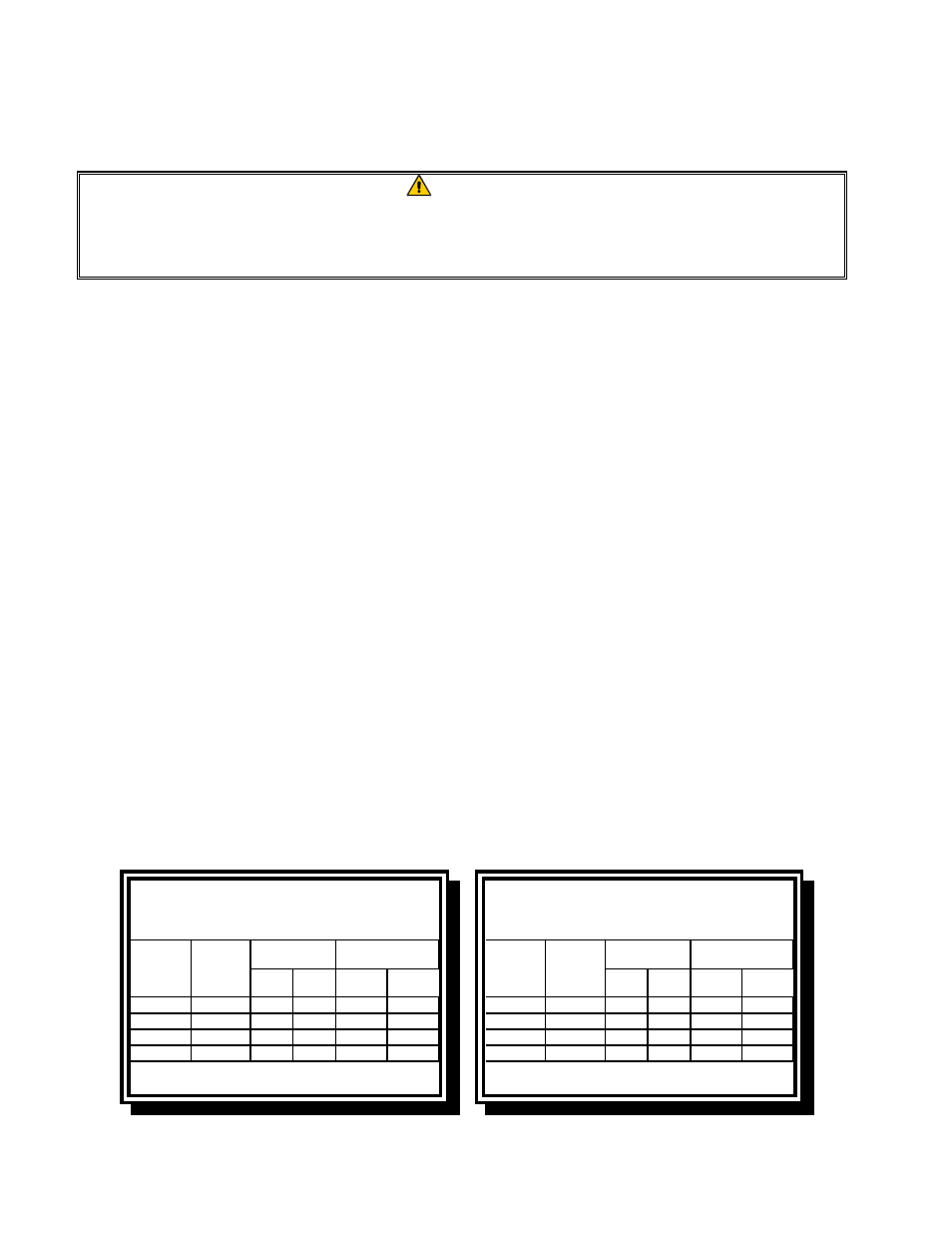

6. Verify the minimum and maximum gas supply pressures for the type of gas to be used in

accordance with the accompanying tables.

Orifice Diameter

Single

Vat

Dual

Vat

Single

Vat

Dual

Vat

G20

20

2 x 3.40 2 x 3.40

7 mbar

7 mbar

G25

20 or 25

2 x 3.40 2 x 3.40

10 mbar

10 mbar

G30

28/30 or 50

2 x 2.05 2 x 2.05

17 mbar

17 mbar

G31

37 or 50

2 x 2.05 2 x 2.05

20 mbar

20 mbar

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured After April 1999

(1) mbar = 10,2 mm H

2

O

Gas

Pressure

(mbar)

(1)

Regulator Pressure

Orifice Diameter

Single

Vat

Dual

Vat

Single

Vat

Dual

Vat

G20

20

2 x 3.40 2 x 3.40

7 mbar

7 mbar

G25

20 or 25

2 x 3.40 2 x 3.40

10 mbar

9 mbar

G30

28/30 or 50

2 x 2.05 2 x 2.05

17 mbar

16,5 mbar

G31

37 or 50

2 x 2.05 2 x 2.05 20,2 mbar 18,5 mbar

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured Through April 1999

(1) mbar = 10,2 mm H

2

O

Gas

Pressure

(mbar)

(1)

Regulator Pressure