Troubleshooting, Instruction manual – Fisher D500243X012 User Manual

Page 12

Instruction Manual

D500243X012

1035/El-O-Matic Actuator

August 2012

12

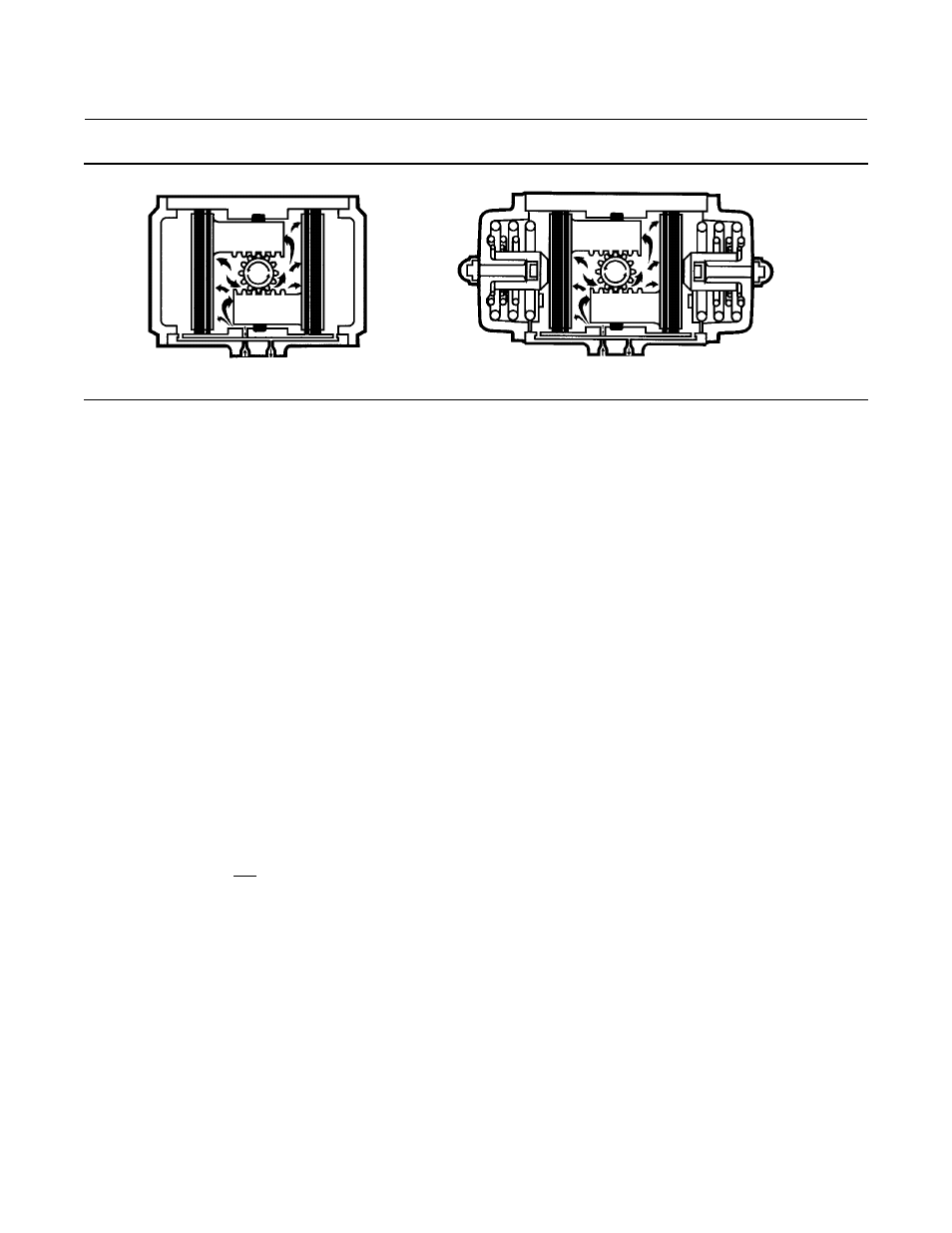

Figure 5 . Code A Assemblies

A

B

A

B

DOUBLE ACTING

SPRING RETURN

A7047

Troubleshooting

If the actuator does not function, make the following checks:

1. Check for worn teeth on piston racks, if the actuator exhibits excessive amounts of backlash. If worn, replace

piston/gear rack assembly.

2. Check supply pressure to ensure the air supply is reaching the actuator. Place a gauge in the line at the inlet of the

actuator. Monitor the gauge for unexpected pressure drops when operating pressure is applied to the actuator.

3. Check piston seal leakage. For spring return actuators, piston seal leakage will show at port B when port A is

pressurized. For double acting actuators, piston seal leakage will show at port B when port A is pressurized, or vice

versa.

4. Check actuator movement. Remove the actuator from the valve. Apply reduced air pressure [0.7 to 1.0 bar (10 to

15 psi) for double acting, or 1.4 to 2.0 bar (20 to 30 psi) for spring return] to see if the actuator will cycle under a

no-load condition.

D

If the actuator cycles under a no-load condition, please refer to the valve instruction manual for valve

troubleshooting or contact your Emerson Process Management sales office.

D

If the spring set number is 5 or 6, it may not cycle with the reduced air pressure amounts listed above and may

require retesting with up to 5.5 bar (80 psi) to stroke a full 90 degrees.

D

If the actuator does not cycle, disassemble the actuator using the Actuator Disassembly procedures. Inspect and

replace parts as necessary.

If the actuator and valve are moving freely, reassemble the valve/actuator assembly and re-test. If unit still fails to

operate, consult your Emerson Process Management sales office for assistance.