Leslie Controls CONTROL VALVES DLOS-2 & DDLOS-2 (150/300) User Manual

Page 5

5

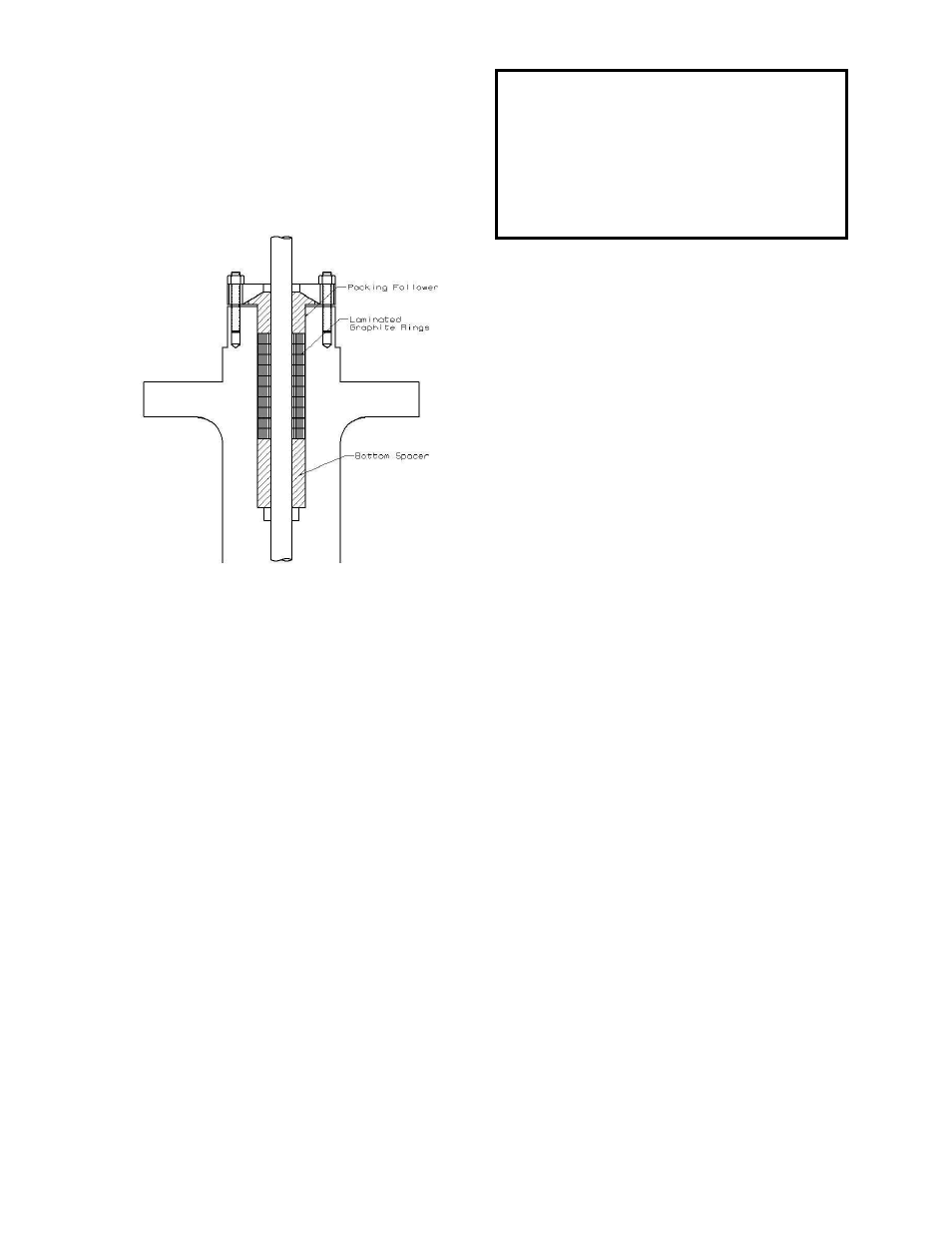

LAMINATED GRAPHITE PACKING

Packing tools are available from Leslie Controls

and should be used to insure proper installation

of packing. Packing tool reference numbers are

shown on Dwg. 10/0.5.9, which also shows how

to make the tools.

Figure 6 - Installation Sequence

INSTALLATION

Place spacers and packing rings over stem and

into packing box in order shown on drawing, one

at a time, seating each firmly and using care not

to tear rings on the stem threads. Adjust packing

gland nuts equally-finger tight plus 1/6 turn (one

flat of nut).

ADJUSTMENT

During start-up some leakage may be observed.

Do not readjust packing-allow at least 15

minutes for pressure/temperature stabilization to

occur. If leakage continues adjust a maximum of

1/6 turn at a time. If pressure is raised

considerably, the packing may leak slightly. Do

not readjust-leakage will stop when new

pressure/temperature stabilization is reached.

BREAK-IN

For best results it is recommended that after

packing installation and adjustment the valve be

fully stroked approximately 20 times to break-in

the packing and reduce stem friction.

DISASSEMBLY OF ACTUATOR FROM

VALVE BODY ASSEMBLY

(See Fig. 6, 6A, 7 and 9 in Appendix)

1.

Close inlet and outlet stop valve and relieve

all pressure from piping involved. Remove

all compression from adjusting spring(s).

2.

NORMALLY OPEN VALVES-DLO(S)-2.

Relieve air pressure from diaphragm of

actuator. Remove the tubing from upper

diaphragm case.

3.

NORMALLY

CLOSED

VALVES-

DDLO(S)-2. Supply sufficient air to the

actuator diaphragm to keep valve plug from

touching seat while disengaging valve plug

stem from actuator stem.

4.

Loosen valve stem nut. Use wrench on plug

stem flats and turn valve plug out of actuator

stem until stems separate. Remove the

tubing from lower diaphragm case.

5.

Remove cap screws holding actuator to

bonnet and lift off actuator.

DISASSEMBLY

VALVE

BODY

SUBASSEMBLY (VBSA)

(See Fig. 6 and 6A in Appendix)

1.

Remove actuator from VBSA as previously

described in Disassembly of Actuator from

Valve Body Subassembly.

2.

Remove bonnet nuts (10). Also bolts (11)

for DLOS only.

3.

Lift bonnet assembly including valve plug

(2) from valve body (1).

4.

Remove valve plug (2), packing bearing

(12) and old packing set (17). Include

spring (15) for Teflon packing set.

WARNING

Injury or death can occur due to failure to

completely isolate valve from all sources of

pressure before beginning disassembly. Do not

proceed until valve has been completely isolated

from the process and vented to atmosphere.