Leslie Controls AEROFLOW SUPPLEMENT Special Live loaded packing User Manual

Leslie Controls Equipment

Page 1 of 1

Installation, Operating and

Maintenance Instructions

Supplement

10/2.5.1.A

Rev. 0

12501 Telecom Drive, Tampa Florida 33637

AEROFLOW SUPPLEMENT

Special “Live Loaded” Packing Arrangement

TABLE OF CONTENTS

INSTALLATION .........................................................................................................................................1

MAINTENANCE .........................................................................................................................................1

PACKING

ADJUSTMENT........................................................................................................................1

ILLUSTRATION INDEX

F

IGURE

1-

L

IVE

L

OADED

P

ACKING

A

RRANGEMENT

................................................................................................................... 1

INSTALLATION

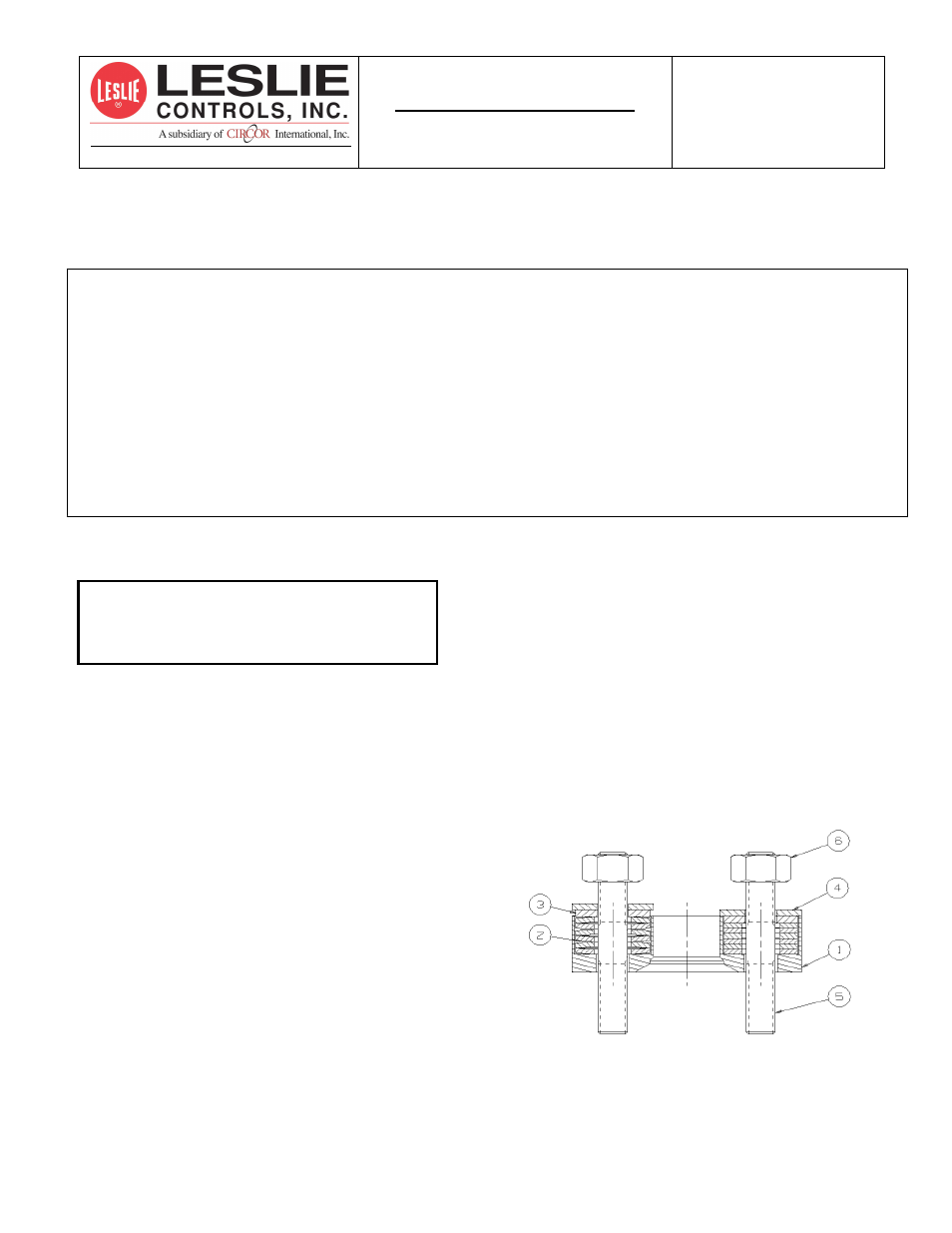

NOTE: Refer to Fig. 1 for installation.

1. Thread packing studs (5) into valve bonnet.

2. With the packing follower and packing installed

(refer to valve IOM) install packing flange (1) onto

valve as shown.

3. Install spring washer (2) as shown on the left

side of Fig. 1 in series.

4. Install spring spacer (3), washer (4) and packing

nut (6) as shown.

5. Tighten the packing nut (6) until the washer (4)

comes into contact with top of the packing flange

(1). This will set the live loaded packing to the

required thrust.

Maintenance

PACKING ADJUSTMENT

1. Once valve has been placed in service, and the

valve has been cycled to pressure/temperature,

the packing nuts (4) may need to be readjusted

(when the valve is depressurized and cools to

ambient). This is due to “new” packing taking a

set when cycled in service.

2. All other packing maintenance, inspection, and

cleaning should follow the guidelines set forth in

the valve IOM.

Figure 1- Live Loaded Packing Arrangement

CAUTION!

All warnings from valve IOM must be followed.