Leslie Controls CONTROL VALVES DLOS-2 & DDLOS-2 (150/300) User Manual

Page 4

4

SECTION III –

MAINTENANCE

To reduce maintenance time refer to proper

drawing and follow steps shown below for

applicable operation.

RENEWING

VALVE

PLUG

STEM

PACKING

(See Fig. 3, Fig. 4 and 5)

Renew valve plug stem packing if control valve

has been in service beyond normal maintenance

and packing shows signs of wear. Wear will be

indicated by leakage at the packing gland. Minor

leakage of graphite packing can be corrected by

tightening the packing flange.

Where

LESLIE

(BRAIDED

TEFLON

GRAPHITE) packing is in use, additional

packing rings can be installed to overcome minor

leakage without dismantling the control valve or

breaking valve plug connection.

Shut down inlet and outlet stop valves and check

that valve body is not under pressure. Remove

nuts and lift packing flange and packing bearing

a sufficient height on valve plug stem to apply a

split packing ring around diameter of valve plug

stem. Lower packing bearing over the new ring,

lower packing flange and tighten sufficiently

with nuts to stop leakage.

To replace LESLIE “TEFLON” packing set or a

complete GRAPHITE 11 packing set, the control

valve must be dismantled.

Installation of Stem Packing

Stuffing box interior and valve plug stem must

be clean, smooth and free from imperfections

that may cause new packing to leak.

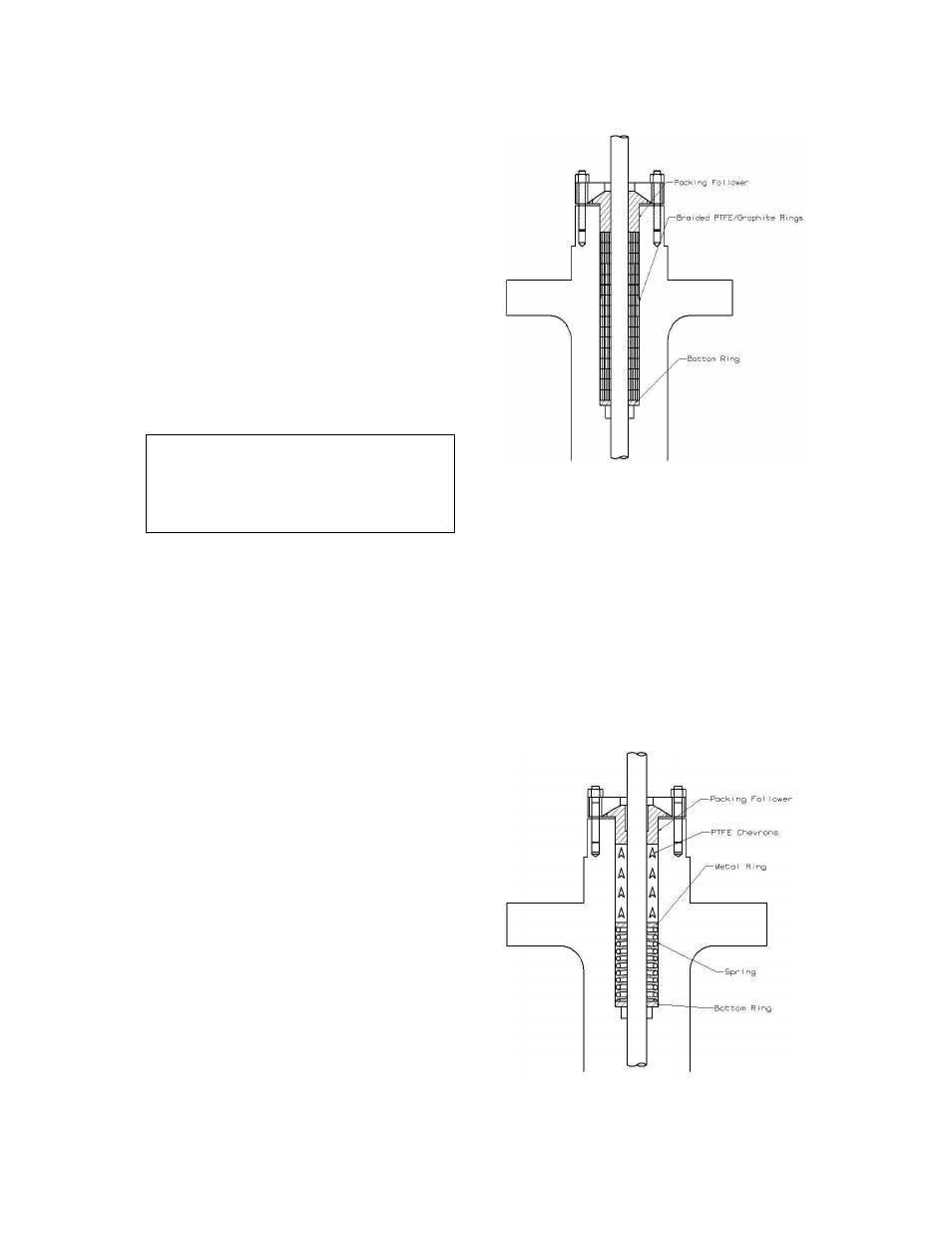

BRAIDED PTFE/GRAPHITE TYPE

PACKING

Figure 4 - Installation Sequence

1.

Place metal ring in stuffing box making sure

it bottoms in box followed by spring and

second metal ring. Install bottom Teflon

adaptor chevron, four Teflon packing

chevrons and top Teflon adaptor chevron in

accordance with Fig. 6.

2.

Install packing follower, packing flange and

nuts. Tighten stuffing box nuts until

follower bottoms on bonnet.

PTFE CHEVRON TYPE PACKING

Figure 5 - Installation Sequence

CAUTION!

Over-tightening of the packing flange

adjustments can cause erratic operation of

the valve.