Leslie Controls CONTROL VALVES DLOS-2 & DDLOS-2 (150/300) User Manual

Page 2

2

SECTION I – INSTALLATION

1.

VALVE POSITION

Install control valve in the highest horizontal line

of piping in an accessible location and with

arrow on side of valve body in direction of fluid

flow. Control valve may be placed in any

position, but upright is preferable for ease of

maintenance.

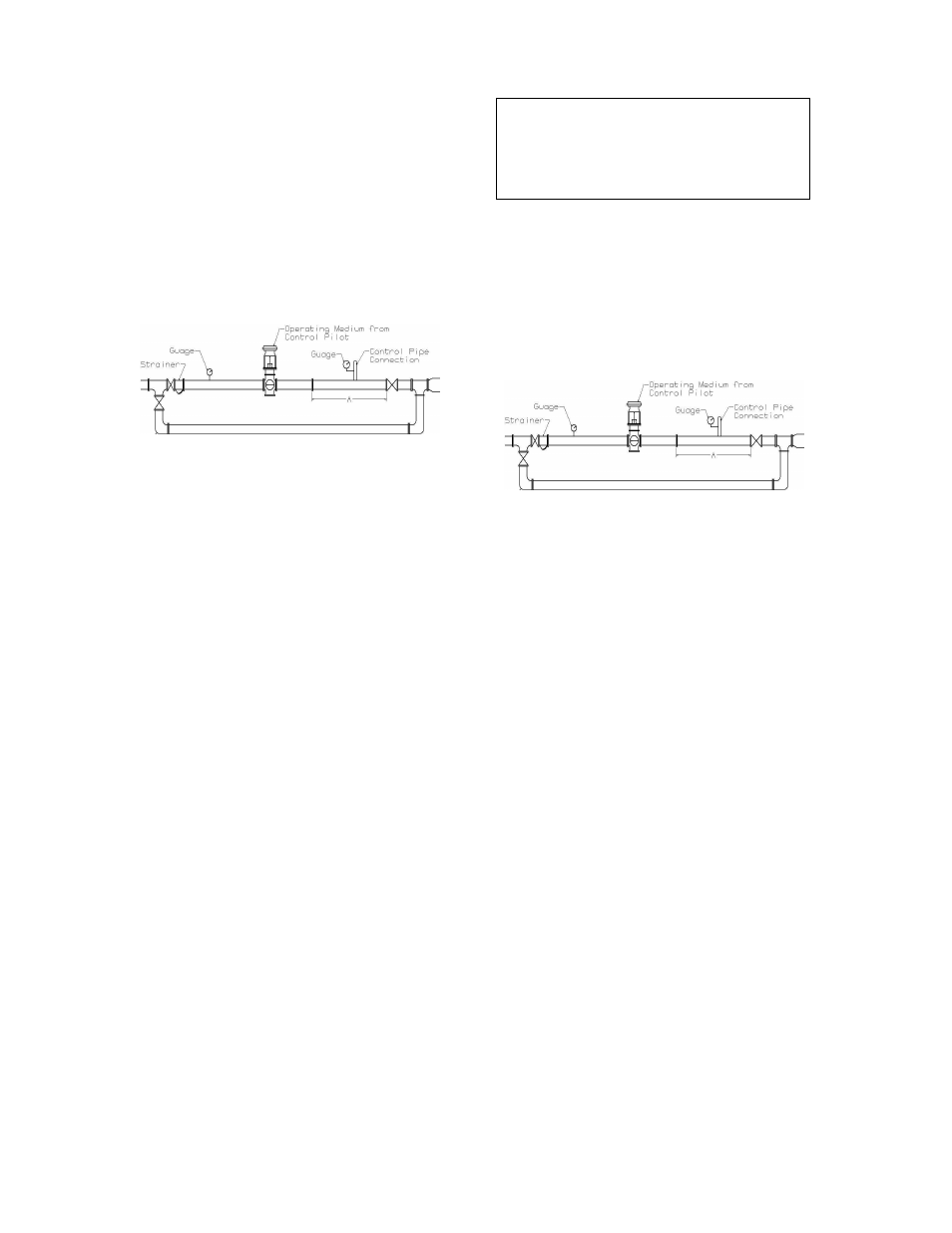

Figure 1 - Typical Installation Expand as

required for fluid flow

2.

PROBLEM PREVENTING

PROCEDURES

•

Provide removal space above, below and

around control valve for easy removal of

parts during maintenance. See Dwg.

10/9.4.1 or 10/9.4.3 for dimensions.

•

Blow or flush out pipelines thoroughly

before installing control valve.

•

Protect control valve and following

equipment with a SELF-CLEANING

STRAINER.

•

Install stop valves and gauges in inlet and

outlet lines to provide means for checking

adjustment and operation of equipment.

•

Provide proper inlet and outlet drainage in

steam service to prevent water hammer or

possible erosion in equipment.

•

Adhere to good piping practice. Install a

bypass around the control valve.

3.

Connect operating medium tubing from

control pilot, instrument or loading device to

diaphragm chamber connection of control

valve or to valve positioner, if one is in use.

Maximum allowable operating pressure for

diaphragm actuators is 60 psig.

4.

Recommended Piping for Control of

Compressible Fluids at Values of 25% or

Less of Inlet Pressure.

Expand outlet pipe to twice control valve inlet

pipe size. Use tapered expander.

•

Connect control pipe for control pilot ahead

of outlet stop valve and at least 2’ to 3’

downstream from end of expander.

•

Make control pipe connection at least 18” to

2’ from outlet stop valve, any elbow or other

flow direction changing fitting.

Figure 2 - Typical Control Valve Station for

Control of Compressible Fluids at 25% or

Less of Inlet Pressure. Expand further as

required for fluid flow.

NOTE: Where sensing impulse is taken 2’ to 3’

downstream from control valve (expander),

dimension “A” minimum of 6’ to 10’ will

provide lowest noise and velocity factors,

accurate pressure sensing and reasonable

bypass length.

SECTION II – OPERATION

1.

Close inlet and outlet stop valves.

2.

Check that control valve responds properly

through rated travel in relation to changes in

operating pressure on the diaphragm. Rated

travel is shown by position of travel

indicator on valve stem relative to travel

indicator scale on yoke.

3.

Manually operate control valves fitted with

manual operating devices through rated

travel to check freedom of movement.

Return manual operating device to its

standby position.

4.

Place control valve in operation in

accordance with instructions furnished with

control pilot or operating device.

CAUTION!

The piping system must be adequately

designed and supported to prevent

extraordinary loads to the pressure