FloAire Compact Direct Fired Heater User Manual

Page 6

6

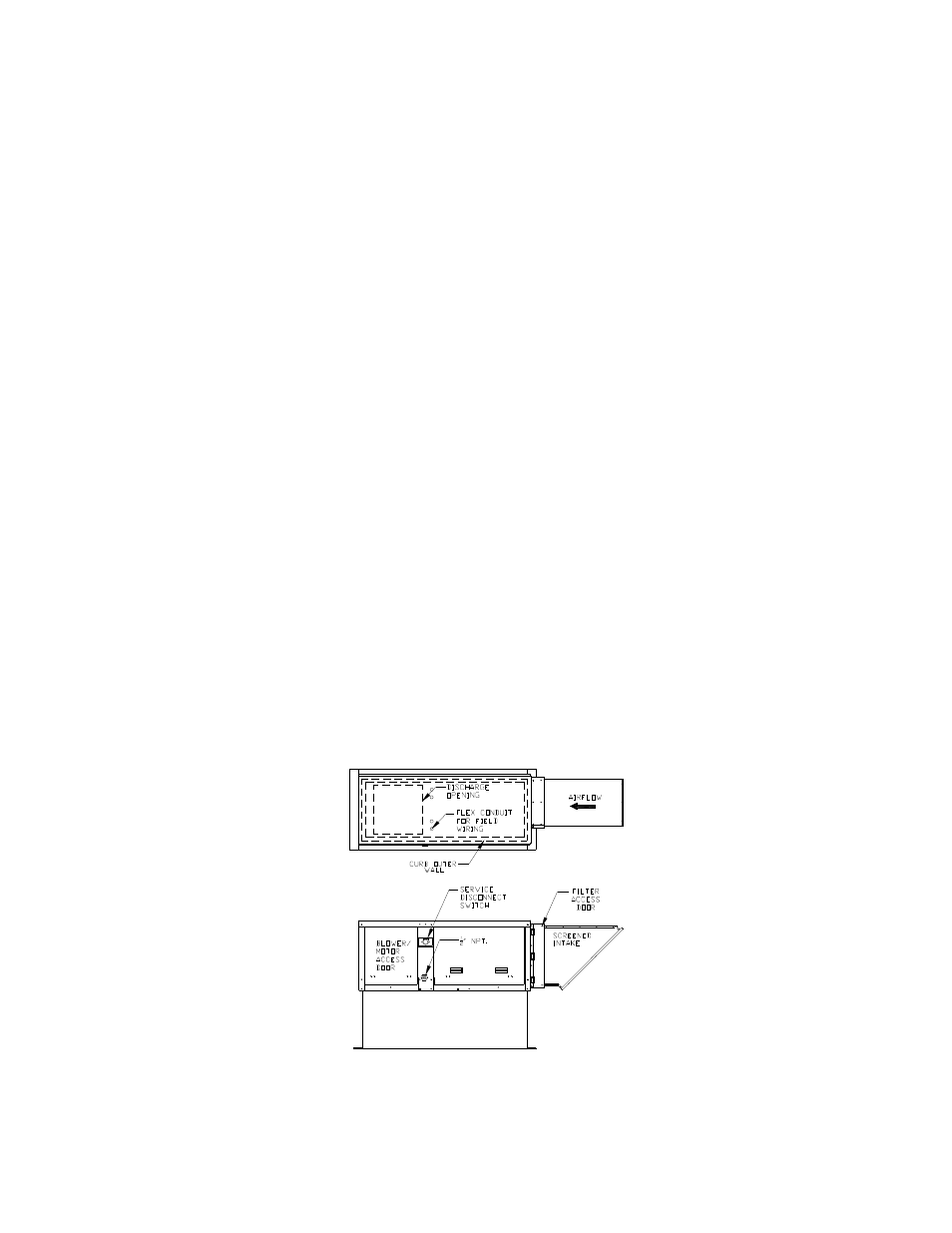

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will

significantly affect the airflow performance. Flexible ductwork and square elbows should not be used.

Also, transitions and turns in ductwork near the fan outlet will cause system effect and will drastically

increase the static pressure and reduce airflow. The minimum fan outlet duct size is 12 inches x 12

inches with a recommended minimum straight duct length of 36 inches. Follow SMACNA guides and

recommendations for the remaining duct run.

Fans designed for rooftop installation should be installed on a prefabricated or factory built roof curb.

Follow curb manufacturer’s instructions for proper curb installation. The unit should be installed on a curb

and/or rail elevated not less than 20” above any surface. Be sure duct connection and fan outlet are

properly aligned and sealed. Secure fan to curb through vertical portion of the ventilator base assembly

flange using a minimum of eight (8) lug screws, anchor bolts, or other suitable fasteners (not furnished).

Shims may be required depending upon curb installation and roofing material. Check all fasteners for

tightness. The diagrams below show different mechanical installation configurations.

Adequate building relief shall be provided so as to not over pressurize the building when the heating

system is operating at its rated capacity. This can be accomplished by taking into account, through

standard engineering methods, the structure’s designed infiltration rate; by providing properly sized relief

openings; or by interlocking a powered exhaust system; or by a combination of these methods.

Heaters installed with intake ductwork must be purged to replace at least four air changes of the volume

of the intake duct.

If the failure or malfunction of this heater creates a hazard to other fuel burning equipment in the building

(e.g. when the heater is providing make up air to a boiler room), the unit is to be interlocked to open inlet

air dampers or other such devices.

Units being installed in airplane hangars should be installed in accordance with the Standard for Aircraft

Hangars, ANSI/NFPA 409. Units being installed in public garages should be installed in accordance

with the Standard for Parking Structures, ANSI/NFPA 88A, or the Standard for Repair Garages,

ANSI/NFPA 88B, and with CAN/CGA B149 Installation Codes.

Roof Mount Installation