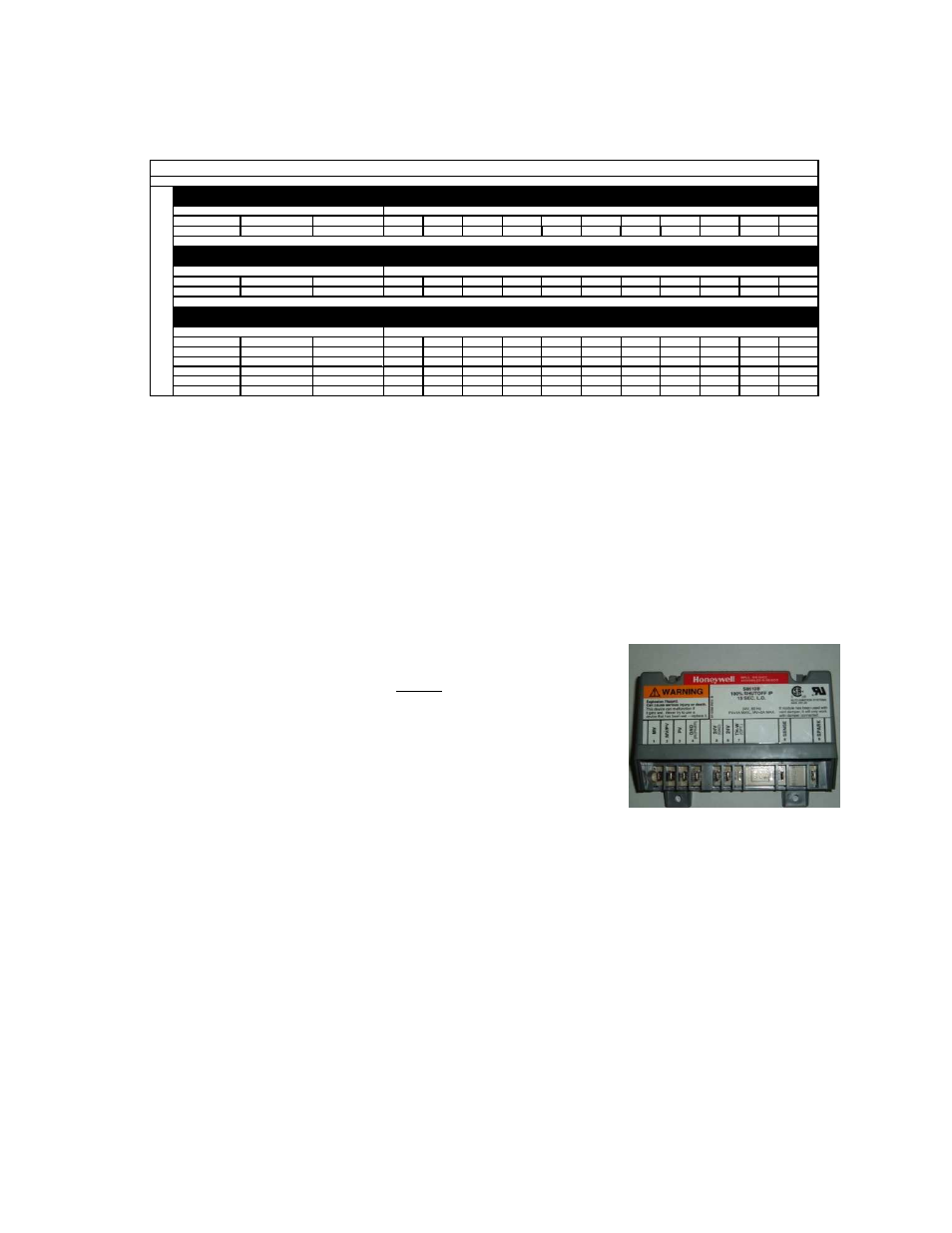

Sequence of operation, Flame safety controller pulley combination chart, Flame safety control – FloAire Compact Direct Fired Heater User Manual

Page 17: 7i n . bl ow e r, Pulley combination chart

17

Flame Safety Controller

Pulley Combination Chart

Motor RPM

1725

1/3 to 1-1/2 HP

MOTOR PULLEY

Dd1

Dd2

Pd1

Pd2

AX BELTS

1VP50

3.4

4.4

3.6

4.6

Open

Closed

BLOWER PULLEY

DATUM DIAMETER

PITCH DIAMETER

5

4 1/2

4

3 1/2

3

2 1/2

2

1 1/2

1

1/2

0

AK32H

3

3.2

1941

1995

2048

2102

2156

2210

2264

2318

2372

2426

2480

1/3 to 1-1/2 HP

MOTOR PULLEY

Dd1

Dd2

Pd1

Pd2

AX BELTS

1VL44

2.8

3.8

3

4

Open

Closed

BLOWER PULLEY

DATUM DIAMETER

PITCH DIAMETER

5

4 1/2

4

3 1/2

3

2 1/2

2

1 1/2

1

1/2

0

AK32H

3

3.2

1617

1671

1725

1779

1833

1887

1941

1995

2048

2102

2156

1/3 to 2 HP

MOTOR PULLEY

Dd1

Dd2

Pd1

Pd2

AX BELTS

1VL40

2.4

3.4

2.6

3.6

Open

Closed

BLOWER PULLEY

DATUM DIAMETER

PITCH DIAMETER

5

4 1/2

4

3 1/2

3

2 1/2

2

1 1/2

1

1/2

0

AK66

6.2

6.4

701

728

755

782

809

836

863

889

916

943

970

AK54

5

5.2

863

896

929

962

995

1028

1062

1095

1128

1161

1194

AK46

4.2

4.4

1019

1059

1098

1137

1176

1215

1255

1294

1333

1372

1411

AK39

3.5

3.7

1212

1259

1305

1352

1399

1445

1492

1539

1585

1632

1678

AK32

3

3.2

1402

1455

1509

1563

1617

1671

1725

1779

1833

1887

1941

TURNS ON MOTOR PULLEY

7

I

N

.

BL

OW

E

R

Pulley Combination Chart

TURNS ON MOTOR PULLEY

TURNS ON MOTOR PULLEY

Sequence of Operation

The direct-fired heater is most easily understood when broken down into smaller individual systems.

There are two main systems, a make-up air fan and a heater. The make-up air fan consists of a blower

and motor. The heater may be further broken down into two control systems, the Flame Safety Control

(FSC) and the Modulating Gas System (MGS). The burner mixes air with the gas (Natural or LP) which

heats the air.

Flame Safety Control

The first system to understand is the Flame Safety

Control. The FSC

is there only to monitor the flame, NOT to control temperature. The

FSC uses a flame rectification sensor mounted on the pilot assembly

to detect the presence of flame in the burner. The FSC is also wired

into an airflow switch, which tells it whether there is proper airflow

through the unit (not just any airflow, but proper airflow). Proper airflow

occurs when there is a .15 in. w.c. to .80 in. w.c. differential

pressure drop across the burner. The FSC controls the opening of

the redundant solenoid gas valves and the operation of the spark

igniter to initiate a pilot flame upon start-up.

Upon a call for heat, there is a 15 second Pilot Trial For Ignition (PTFI).

During PTFI, the FSC opens the pilot gas valve and allows gas to flow

to the pilot assembly. At the same moment, the spark igniter is started,

causing the spark to ignite the pilot gas. When the flame rod sensor detects the flame it powers the

modulating gas system. This is the normal operating mode. The FSC continues to monitor the flame and

airflow. Once this occurs, the unit is in a main flame cycle and thus powers the main gas valve and the

modulating gas system. This is the normal operating mode. The FSC continues to monitor the flame and

airflow. If the flame fails to light after 15 seconds of sparking, the FSC goes in to lock-out mode. Anytime

this occurs, the problem must be diagnosed and corrected to avoid future lockouts after resetting. To

begin troubleshooting, or to reset the FSC, shut down power to the heater and restart the heater. This

will clear the alarm from the flame safety.