Main burner adjustment – FloAire Compact Direct Fired Heater User Manual

Page 14

14

Maxitrol M411 Low Fire

Bypass Screw

Mod Valve Voltage Summary

Volts DC

Firing Mode

0 to 5 VDC

Low Fire

5 to 15 VDC

Modulation

15 to 20 VDC

High Fire

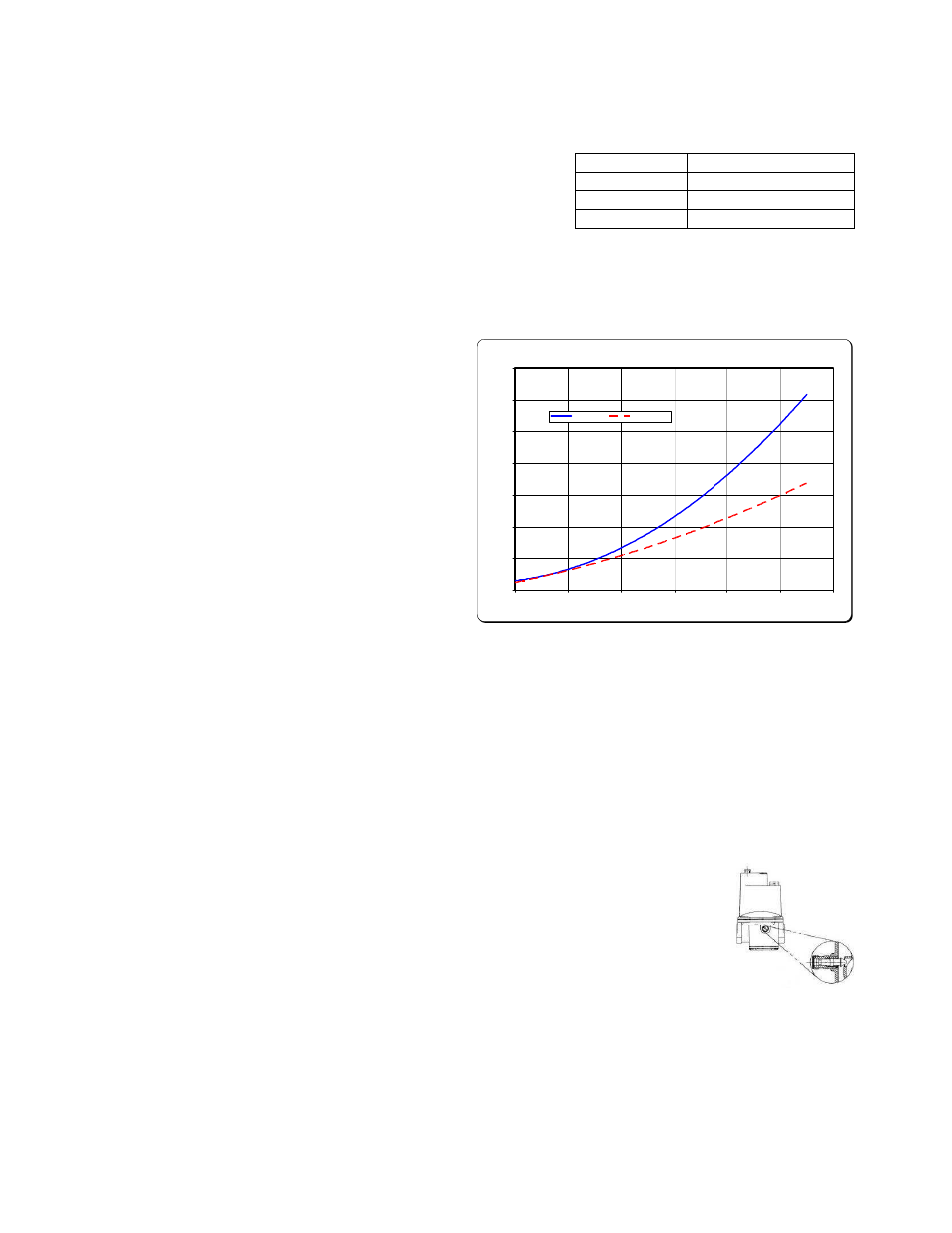

Average Man ifold Pressu re vs. Firin g Rate/Ft. of Burn er

-1.00

0.00

1.00

2.00

3.00

4.00

5.00

6.00

0

100000

200000

300000

400000

500000

600000

Firing Rate (BTU/Hr/Ft. of Burner)

M

a

n

if

o

ld

P

re

s

s

u

re

(

in

.

w

.c

.)

Natural Gas

Propane Gas

Main Burner Adjustment

1. Once the pilot has been properly established, the

manifold gas pressure or temperature rise should be

adjusted to jobsite conditions. The gas pressure

regulator integral to the combination gas control is

adjusted at the factory for average gas conditions. It is

important that the gas be supplied to the burner in

accordance with the input rating on the rating plate.

2. Create a high fire call for heat. This should be done with the blower on and all gas controls on.

High fire can be achieved by removing the wire at terminal #4 (remove wires #2 and #4 for

Maxitrol 44 systems) from the Maxitrol 14 amplifier.

3. The manifold pressure should be checked

at the pressure tap downstream of the

modulating valve. The graph to the right

indicates the proper manifold pressure for

the desired amount of BTUs per foot of

burner. For natural gas systems, the high

fire manifold pressure should not exceed 5

in. w.c. For propane gas, the high fire

manifold pressure should not exceed 2.5

in. w.c. Another method of checking high

fire is to measure the temperature rise of

the unit. The temperature rise should be

set to design conditions and typically is

minimum 70°F.

4. Remove the cap from the combination gas

valve regulator adjustment. Using the

regulator pressure adjusting screw, adjust

the high fire manifold pressure to 5 in. w.c. maximum for natural gas and 2.5 in. w.c. maximum for

propane gas. High fire should be set to generate the desired temperature rise. If the high fire

screw is at the end of its adjustment and more pressure is needed, then adjust the main building

gas pressure regulator spring (located external to the unit) to achieve the proper manifold

pressure. Turning the regulator screw clockwise will increase pressure and counter-clockwise will

decrease pressure.

5. Reconnect the wire on the Maxitrol 14 amplifier at terminal #4 (wires #2 and #4 for Maxitrol 44).

6. The low fire manifold pressure must now be set. Low fire can be achieved by removing the wire

at terminal #5 from the Maxitrol 14 amplifier (remove #8 for Maxitrol 44).

7. Using the bypass screw located on the side of the M411, adjust the low fire manifold pressure

until there is a very thin flame along the entire length of the burner. No

dark spots should be seen in the burner. The burner may be observed

through the view-port located on the external wall of the heater. Replace

the cap to the Maxitrol valve and restore all of the original wiring on the

Maxitrol amplifier and gas components.

8. A final gas leak check shall be performed to verify the gas-tightness of the

heater’s components and piping under normal operating conditions. This

can be done by measuring the gas pressure at the ¼” gas plug just

downstream of the modulating valve.