Industrial Data Systems IDS 440 User Manual

Page 48

IDS440 Users Manual version 4.2

Parameter Functions

44

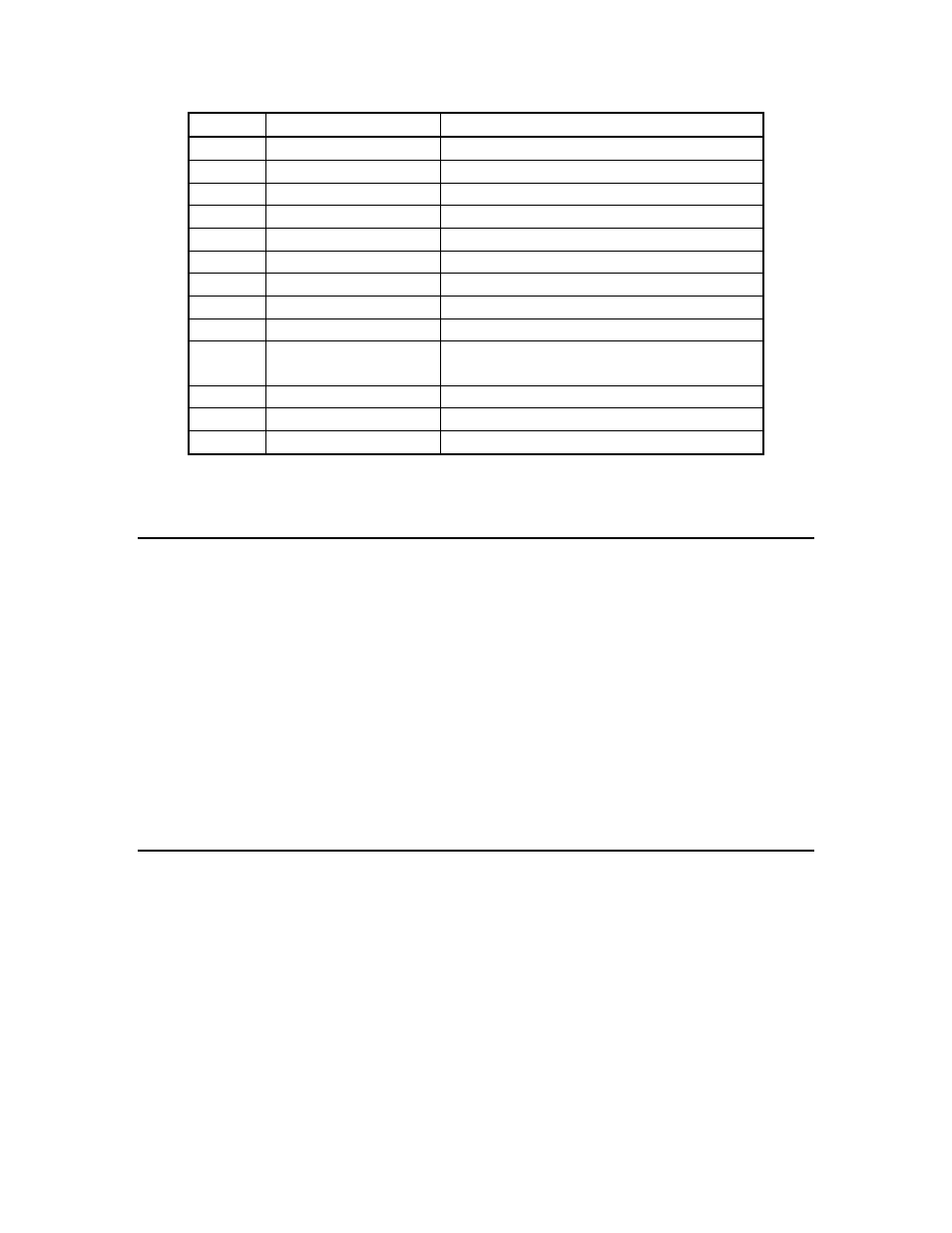

Test # Hardware Tested

Description

1

Serial Com. Port 1

Display input data.

2

Serial Com. Port 1

Display input error count.

3

Serial Com. Port 1

Transmit data.

4

Serial Com. Port 2

Display input data.

5

Serial Com. Port 2

Display input error count.

6

Serial Com. Port 2

Transmit data.

7

Parallel Port

Transmit data.

8

A/D converter

Display raw conversion data.

9

Ram Memory

Test memory for errors.

10

Display

Turn on all LED’s and display

segments.

11

Configuration

Print the EAROM configuration data.

12

Serial Com. Port 1

Transmit/Receive loop-back test.

13

Serial Com. Port 2

Transmit/Receive loop-back test.

See section:

Diagnostic Tests for more information on each test.

Function 70 Initialize Operation Parameters to Factory Defaults

Use function 70 to reset the IDS440’s operation parameters to their factory default

values. This function is used to reset the IDS440’s earom when a new EPROM program

is installed. Do NOT use this function unless you are ready to begin installation from the

beginning.

1. Hold the CLEAR key down and press the ENTER key to enter the configure mode.

2. Enter CFG 70. The IDS440 prompts, “rESEt”. Press the ENTER key to reset

operation parameters or press the CLEAR key to exit without changing the operation

parameters.

3.

NOTE: enter 10809 when the display prompts, “rESEt” to reset the calibration

factors to the factory defaults.

Function 71 Configure Event Monitor

Use function 71 to enter setpoint data into the Event Monitor. See the “Scale Basic /

Event Monitor” manual” for more information on the event monitor parameters.

1. Hold the CLEAR key down and press the ENTER key to enter the configure mode.

2. Enter CFG 71. The IDS440 prompts “Eno”. Enter the Event number to be modified.

3. The IDS440 prompts “P0 xx” where P0 is parameter 0 and xx is the current value of

parameter 0. Enter new data for P0 or press the ENTER key to use the displayed

data.