Accessories, Nfx'was – Panasonic EY7541 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

N-JT

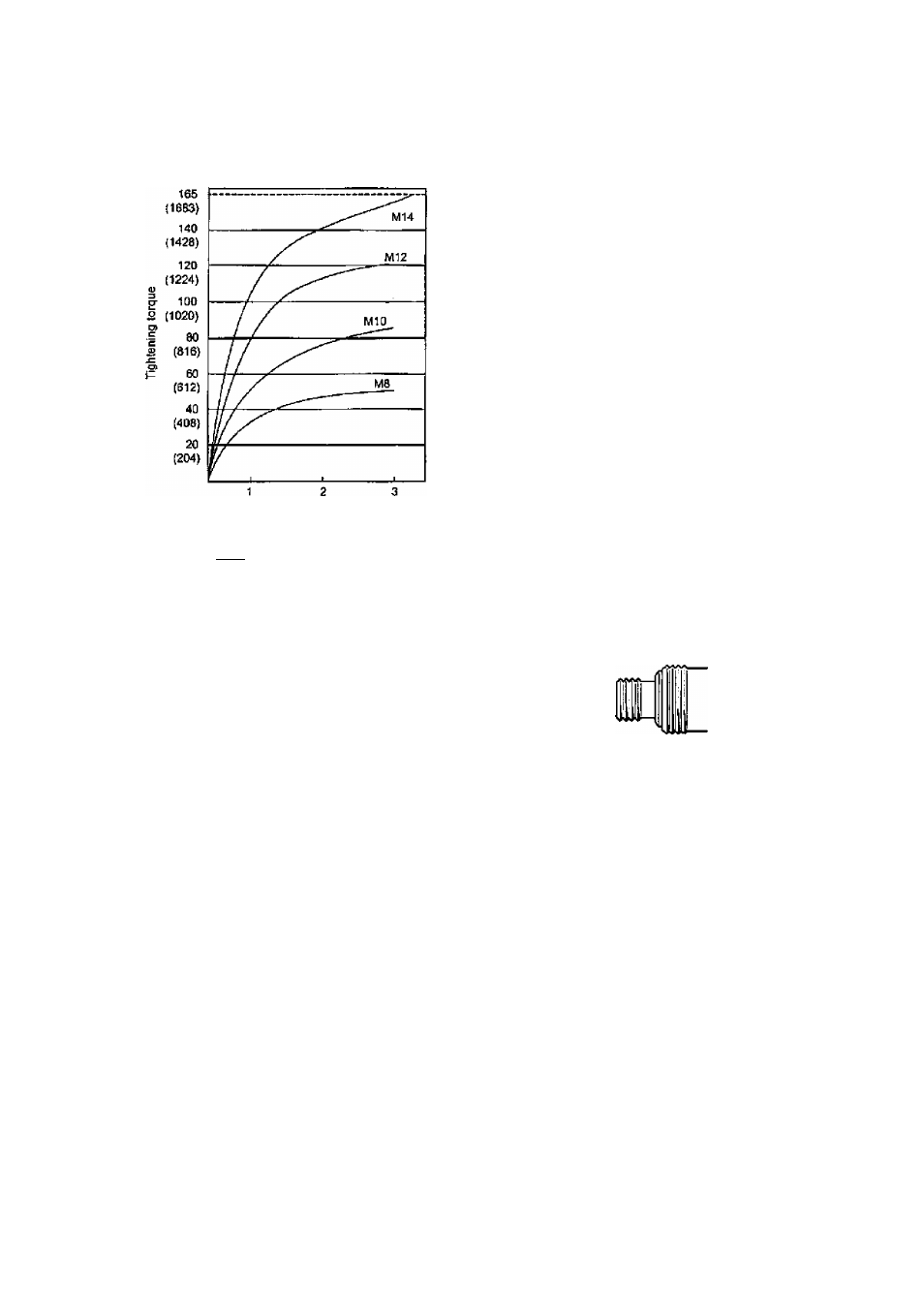

(ktf-cm) M8, MIO. M12, MU High tensile boll

Tightening time (Sec.)

Bolt-

cnv-

Washer

7777 Steel plate

Nut

nfX'Was

LJ ' Sorf

thicknesslO mm (3/8")

Washer

Spring washer

Tighteriing conditions

• The following ix>lls are used. .

Standard bolts; Strength type 4.8

High tensile type 12.9

'^Explanation of the strength type

4.8

;—- Bolt yield point

(80% of tensile strength)

32 kgf/mm2 (45000psi)

—, Bolt tensile strength

40 kgf/mm^ (seOOOpsi)

4) Tightening conditions

• Tightening torque vwli vary, even with the

same bolt, according to grade, length, and

torque coefficient (the fixed coefficient indi

cated by the manufacturer upon produc

tion),

* Tightening torque will vary, even with the

same bolting material (e.g. steel), accord

ing to the surface finish,

•Torque is greatly reduced when the bolt

and nut start turning together.

5} Socket play

Torque is lowered as the six-sided configu

ration of the socket of the wrong size is

used to tighten a bolt.

6) Switch (Variable speed control trigger)

Torque is lowered if the unit is used with

the switch not fully pulled out.

7) Effectof Connecting Adaptor

The tightening torque will be lowered

through the use of a universal joint or a

connecting adaptor.

VI.

ACCESSORIES

Use only bits suitable for size of drill's chuck.

Use Panasonic original Optional Quick change

chuck (EY9HX110E) for maximum performance.

2) Tightening time

Longer tightening time results in increased

tightening torque. Excessive tightening,

however, adds no value and reduces the

iffe of the tool.

3) Different bolt diameters

The size of the bolt diameter affects the

tightening torque.

Generally, as the bolt diameter increases,

tightening torque rises.

- 12 -