INCRA Build-It STS Mortiser User Manual

Page 8

INCRA Build-It STS Mortiser Manual

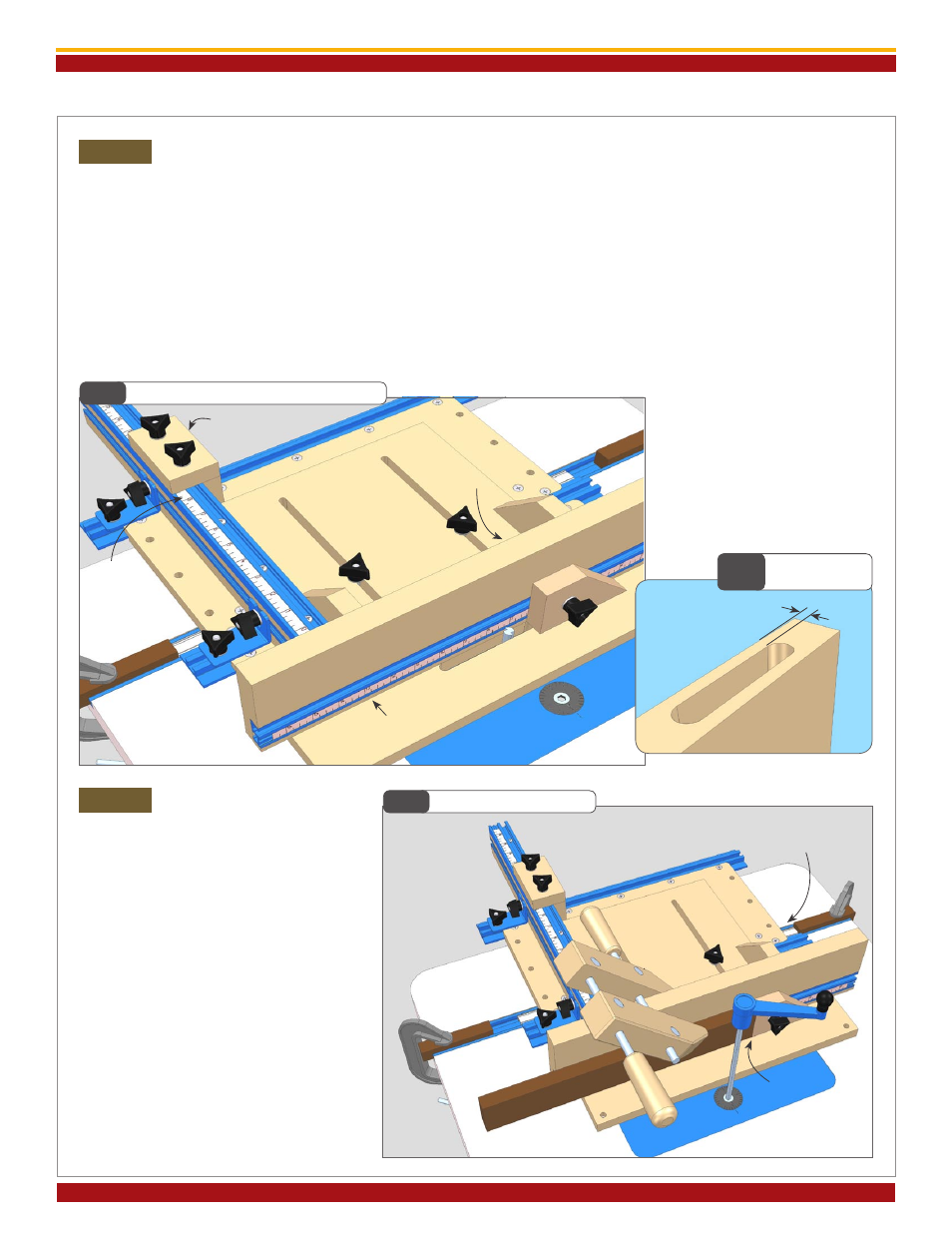

Set Distance from Edge of Slot to

Edge of Workpiece

You’ll first want to zero the faceplate to the edge of the cutter.

Loosen the clamping knobs that secure the faceplate assembly

and slide it forward to contact the cutting wing of the bit.

(You may need to rotate the cutter to find the “high spot”

of the cutting wing.) Hold the faceplate assembly steady as

you slide the T-Track fence stop positioner up to contact the

back of the faceplate assembly’s base and tighten the clamping

knobs. Note the position of the stop on the scale in the top

of the T-Track fence. (We suggest you slide the scale to read

at one of the whole inch numbers, or slide it to read at zero

if you don’t mind some of the scale hanging out of the end

of the fence.)

To set the cutter-to-faceplate distance, simply move the

T-Track stop positioner away from the back of the base

using the scale on the top of the T-Track fence as

a reference. Tighten the clamping knobs, then slide the

faceplate assembly back to contact the stop and tighten the

clamping knobs,

Fig. 24. For example, if we start with the

stop positioner set at 8” and

then move it to 8-

1

/

2

” along

with the faceplate assembly,

there should be

1

/

2

” between

the faceplate and cutter.

Page 7

Fig.24

Setting Slot to Board Edge Distance

Cutting the Slot

Now you can clamp your workpiece in

place and start the cutting process. Lower

the cutter until it is just flush with the top

of the Build-It throat plate. For horizontally

oriented material, place the board end

against the faceplate stop and clamp to

the faceplate.

Always begin and end

each cut with the jig against the

outfeed travel limit block. Turn on

the router and, using your router lift’s crank

handle, raise the cutter

1

/

16

” and slide the

jig between the two limit stops,

Fig. 25.

After each cut cycle, raise the cutter

1

/

16

”

until you reach the desired depth. You’ll

have to count the crank handle rotations

to keep up with how deep your cut is.

Fig.25

Cutting a Slot Mortise

Step 3

Step 4

Fig.23

Slot to Board

Edge Distance

3rd: slide faceplate assembly

to stop and clamp in place

T-Track

fence stop

2nd: using

scale as a reference,

slide stop away

by an amount equal

to desired slot-to-

edge distance

1st: slide faceplate to contact

cutter, then slide T-Track

fence stop to contact back

of faceplate assembly

ALWAYS begin and end each

cut with jig against the outfeed

travel limit stop block

clamp horizontal

material to

faceplate with

end against

faceplate stop