INCRA Build-It STS Mortiser User Manual

Page 11

INCRA Build-It STS Mortiser Manual

Page 10

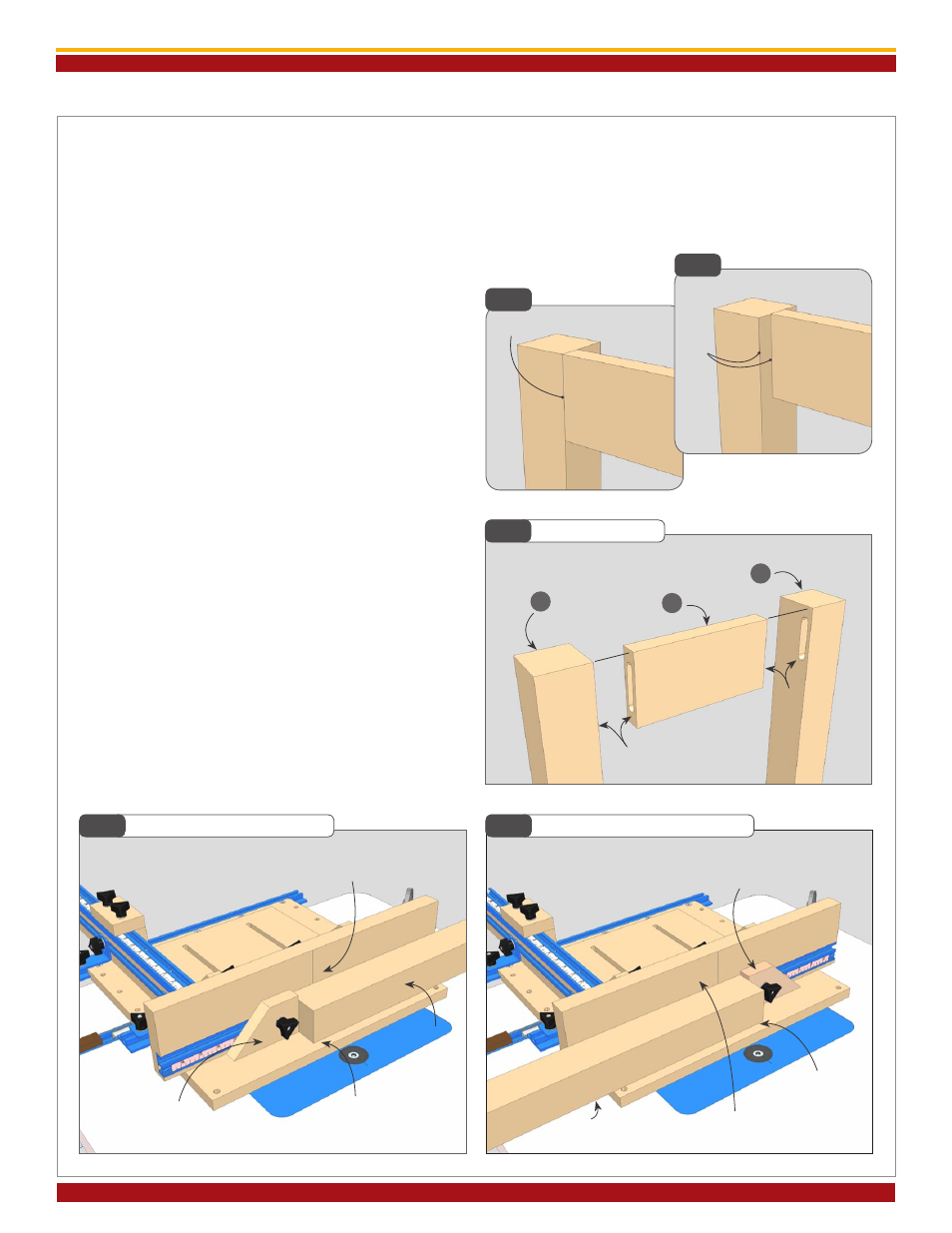

As in most woodworking projects, the alignment between

parts is an important part of the finished look of the

construction. Sometimes, you’ll want a flush alignment as

shown in

Fig. 32, while other projects may require offset

alignments,

Fig. 33. Either way, you’ll want to be able to

control and maintain the alignment selected. This is often

accomplished through the use of reference marks placed

on the individual parts. These marks are then used to

ensure the correct face or edge of the material is placed

against the fence when setting up for a cutting operation.

Work piece reference marks used with your STS Mortiser

will also help in determining whether you will need an infeed

or outfeed faceplate stop when setting the slot to end of

board distance.

For example, in order to keep the flush alignments shown

in

Fig. 34, you’ll mark the surfaces that you want aligned

and the surfaces that will receive a cut. We have used

the letter “F” to designate the surface that will be placed

against the faceplate, and the letter “C” to represent the

surface that will receive the cut. The pieces are numbered

1, 2 & 3. When cutting the #1 piece, it would be necessary

to use an infeed faceplate stop in order to position surface

“F” against the faceplate, with surface “C” face down over

the cutter,

Fig. 35.

When cutting the same mortise on the #3 piece, however,

the setup would require the use of an outfeed stop in

order to position the material with the “F” surface against

the faceplate and the “C” surface face down,

Fig. 36.

The procedure is the same for offset alignments, except

that the edge-to-cutter distance is changed when setting

up for the cuts on piece #2.

Fig.35

Using Infeed Faceplate Stop

Fig.36

Using Outfeed Faceplate Stop

Fig.34

Reference Marks

Fig.32

Fig.33

flush alignment

offset

alignment

F

1

2

3

F

F

F

C

C

infeed

faceplate stop

“

F

” mark is against

the faceplate

“

C

” mark is face

down over cutter

piece #3

outfeed faceplate stop

“

C

” mark is

face down

“

F

” mark is

against the faceplate

piece #1