Operation – INCRA Build-It STS Mortiser User Manual

Page 6

INCRA Build-It STS Mortiser Manual

Page 5

Operation

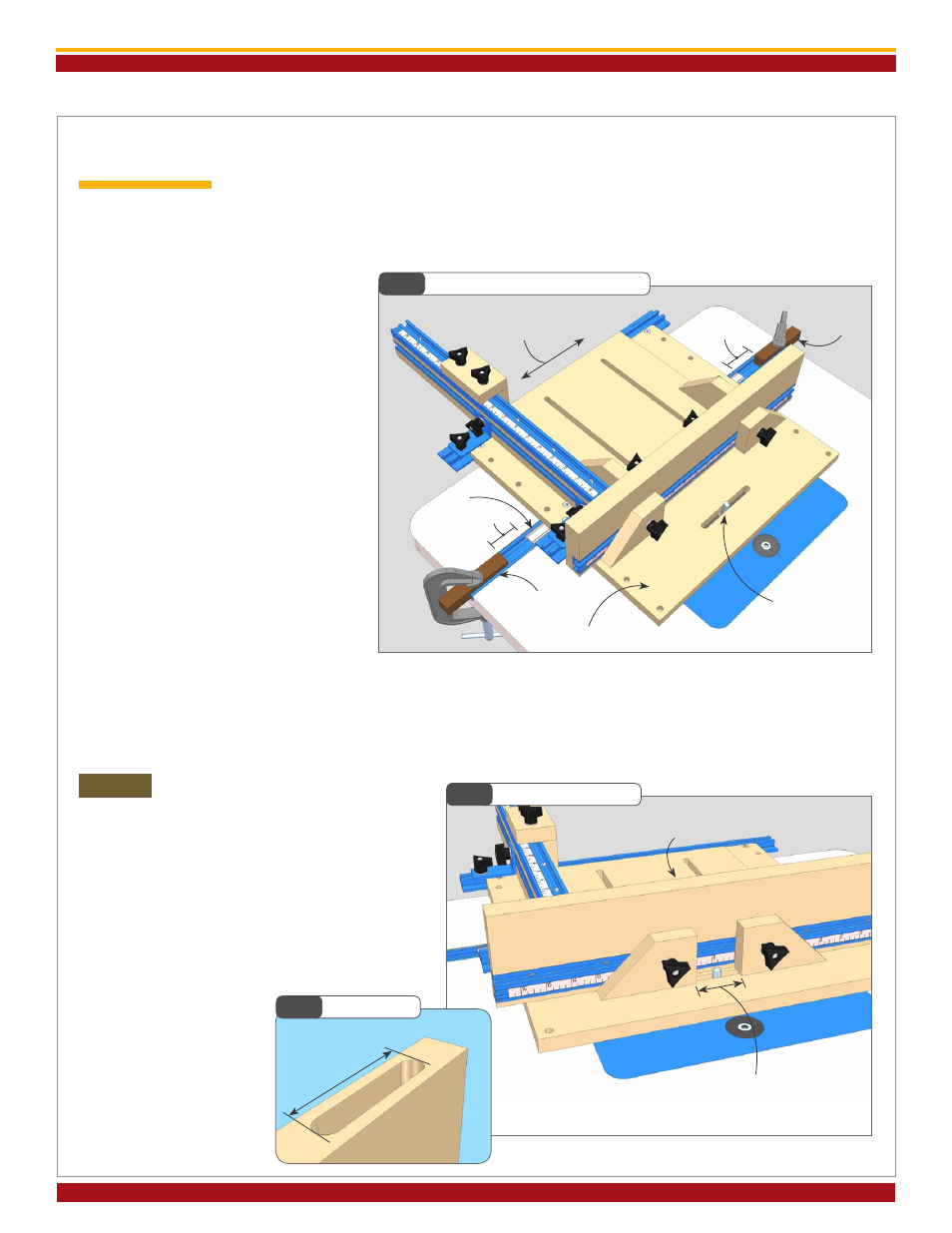

Set Length of Slot

To set the length of your slot, raise the cutter through

the slotted hole in the throat plate panel and slide

the faceplate assembly up to (but not touching)

the cutter. Before tightening the faceplate assembly

clamping knobs, make sure that it is pressed securely

against the T-Track fence. Slide a faceplate stop into

each end of the T-Track on the faceplate. In setting

the stops, you will always use the 8” mark on the faceplate

scale to represent the “center” of your slot length. To

set up for a 2” long slot, set

the outfeed faceplate stop

to 7” and the infeed stop

to 9”. In other words, the

distance between the two

stops is equal to your slot

length,

Fig. 18.

Fig.18

Setting Slot Length

For typical slot mortising there are four steps to locating a slot on your work piece.

Step 1

Fig.17

Slot Length

Fig.16

Cut Slot Through Throat Plate

Slide STS Jig between two stop

blocks as you slowly raise cutter

2”

2”

Miter Slider

3

/

8

” straight bit

Build-It “throat plate”

outfeed

stop block

infeed

stop block

For your first mortise, you’ll cut a slot about 4” long through the “throat plate” Build-It Panel that overlaps the cutter at

your router table. Since most loose tenon applications in

3

/

4

” stock work well with a

3

/

8

” tenon, we’ll cut the slot with

a

3

/

8

” straight bit. (The longer the cutter

length, the deeper you’ll be able to cut your

slot mortises later on.) Install the cutter and

lower the bit below your tabletop. Place the

STS Mortiser on your router table and center

it on the length of your miter slot. Now

clamp a

3

/

4

” x

3

/

4

” x 3” block of wood into

the infeed and outfeed ends of the miter slot

2” from the ends of the Miter Slider,

Fig. 16.

Slide the right angle faceplate assembly and

T-Track fence away from the area directly

above the cutter and turn the router on.

Use your router lift crank handle to raise

the cutter

1

/

16

” per pass as you slide the jig

back and forth between the two stop blocks

clamped to the table.

CAUTION: ALWAYS START AND STOP ANY

SLOT CUTTING OPERATION WITH THE

JIG POSITIONED AGAINST THE OUTFEED

STOP BLOCK.

When you have cut through the throat plate, turn off the router. The throat plate provides support for your

work piece and zero clearance for tear out control. If you choose to cut mortises with a larger or smaller diameter cutter,

additional throat plates can be produced. Your new STS Mortiser is now ready to use.

set distance between stops equal

to desired slot length

(use 8” mark on scale as center)

slide faceplate to cutter and clamp in place