Torque chart, Torque chart 18.0, Caution – Gradall G6-42P (91404003_Before 0160004017) Operation Manual User Manual

Page 43

Form No. 20027 • G6-42P Owner/Operator Manual

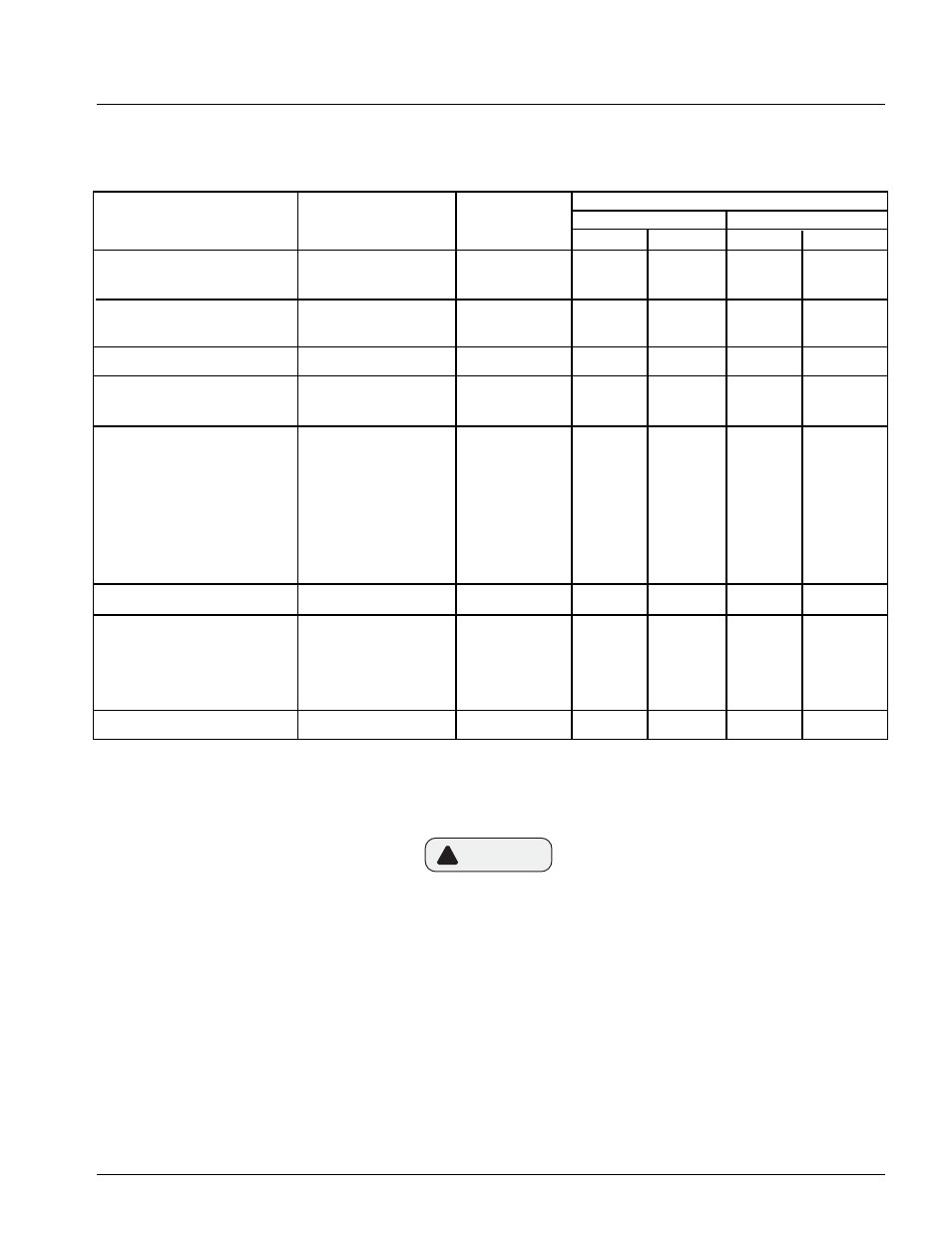

TORQUE CHART

18.0

TORQUE (lubricated)

ITEM

FREQUENCY*

THREAD SIZE

FT.-LB.

Nm

(GRADE)

MINIMUM

MAXIMUM

MINIMUM

MAXIMUM

Boom Slide Bearings (front)

5 Weeks (250 hrs)

3/8-24 (5)

32

37

43

50

5 Weeks (250 hrs)

1/2-20 (5)

76

86

103

116

Boom Slide Bearings (rear)

If front bearings have

3/8-24 (5)

32

37

43

50

worked loose

1/2-20

76

86

103

117

Boom Chain Jam Nuts

Annually (1500 hrs)

7/8-14

100

125

136

169

Cab Mounting Bolts (upper)

7/8-9

530

565

719

766

(lower)

3/4-10

340

365

461

495

Engine Assembly

Flywheel Housing Bolts

Annually (1500 hrs)

M10

38

48

52

65

Flexplate Mounting Bolts

Annually (1500 hrs)

3/8-16

40

45

54

61

Hydrostatic Trans Bolts

Annually (1500 hrs)

3/4-10 (5)

240

265

325

359

Engine Mounts

Annually (1500 hrs)

M12

66

76

89

103

M16

166

181

225

245

Front Axle Motor to Axle Bolts

Annually (1500 hrs)

M20

324

349

439

473

Rear Axle

Hub Assembly Mntg Bolts

Annually (1500 hrs)

3/4-10

270

290

366

393

Steering Cylinder Rod to

Knuckle Mntg Pin (Bottom)

6 Months (1000 hrs)

1 1/4-12

280

305

380

414

Wheel Lug Nuts

3 Months (500 hrs)

-

350

400

474

542

* Check torque at whichever interval occurs first.

The preceeding bolt torque chart covering English and

Metric fasteners are used by Gradall engineering. Gradall

ratings are for lubricated fasteners. Do not exceed the

allowable rating. An over-torqued bolt in most cases will

fail as rapidly as an under-torqued bolt.

CAUTION

!

To check GRADALL torque values, set the torque wrench at 95% of rated torque value and check fastener. If the

torque wrench releases before the fastener moves, assume fastener torque is correct. When setting GRADALL

torque values, use the values given on the following chart. Do not exceed allowances.