Prochem Apex GTX User Manual

Page 57

55

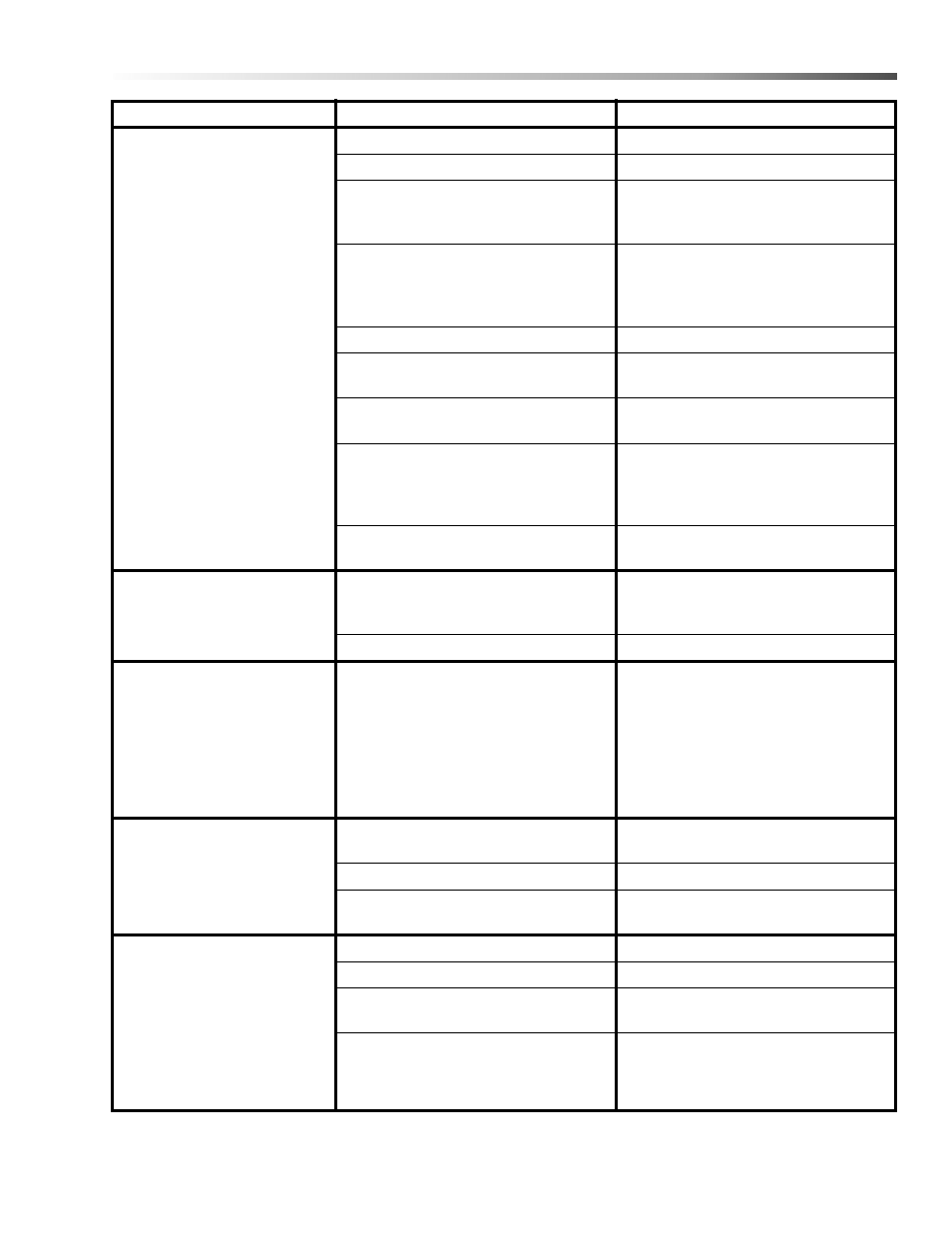

Maintenance

Problem

Cause

Solution

Engine stops running.

While doing normal cleaning,

the engine stops running.

Engine is out of fuel

Add fuel to the fuel tank.

Waste tank is full

Empty waste tank.

Main or engine circuit breaker on the

control panel has been tripped.

After inspecting the unit to determine

the cause of the tripped circuit breaker,

press the reset button.

Engine coolant temperature has

exceeded 240°F, triggering the high

temperature switch to shut the unit

down.

Determine the cause of the over-

heating before restarting the unit. Refer

to the Kubota Engine Operation and

Maintenance Manual.

Defective fuel pump.

Replace fuel pump.

Defective float switch inside the waste

tank.

Check switch for proper operation.

Replace as necessary.

Defective 240°F engine coolant high-

temperature shutdown switch.

Test switch. If necessary, replace.

Oil pressure gauge on engine has shut

down, due to insufficient oil pressure.

Refer to the Kubota Engine Operation

and Maintenance Manual. DO NOT

restart the engine until the cause is

determined and corrected.

No ignition in the engine or engine is

malfunctioning.

Refer to the Kubota Engine Operation

and Maintenance Manual.

Excessive heating

Flow restriction caused by hard water

scaling.

Descale unit, repair or replace

damaged plumbing components as

necessary. Install water softener.

Not enough water flow.

Check jet size of tool.

Heat exchanger leaks.

NOTE: The exhaust heat

exchanger will produce water

condensation discharge at

times during normal operation.

DO NOT confuse this with a

leak.

Engine/vacuum exhaust heat

exchangers are damaged from frozen

water.

Inspect heat exchangers for leaks.

Visually inspect for damage. Pressure

check after removing from the unit.

(Maximum test pressure 1200 PSI).

Loss of temperature.

The heat output of the unit is

LESS than normal.

Temperature relief valve on water box

is stuck open.

Clean temperature relief valve and

test. Replace, if necessary.

Engine RPM is low.

Reset engine RPM.

Defective temperature gauge.

Test gauge and sensor. Replace failed

component.

Automatic waste pump is

malfunctioning or not operating

normally.

NOTE: When replacing either

the pump or float switch on

internal (in tank) pumpout, use

new electrical connectors and

heat shrink. Inspect connec-

tion for watertight seal.

Defective waste pump float switch.

Replace float switch.

Broken diaphragm.

Replace diaphragm.

Weak battery.

Charge or replace battery if needed.

Check charging station.

Pump-out circuit breaker on control

panel has been tripped.

After inspecting waste pump to

determine the cause of the tripped

circuit breaker, press the reset button.

86341750 APEX GTX