Prochem Apex GTX User Manual

Page 55

53

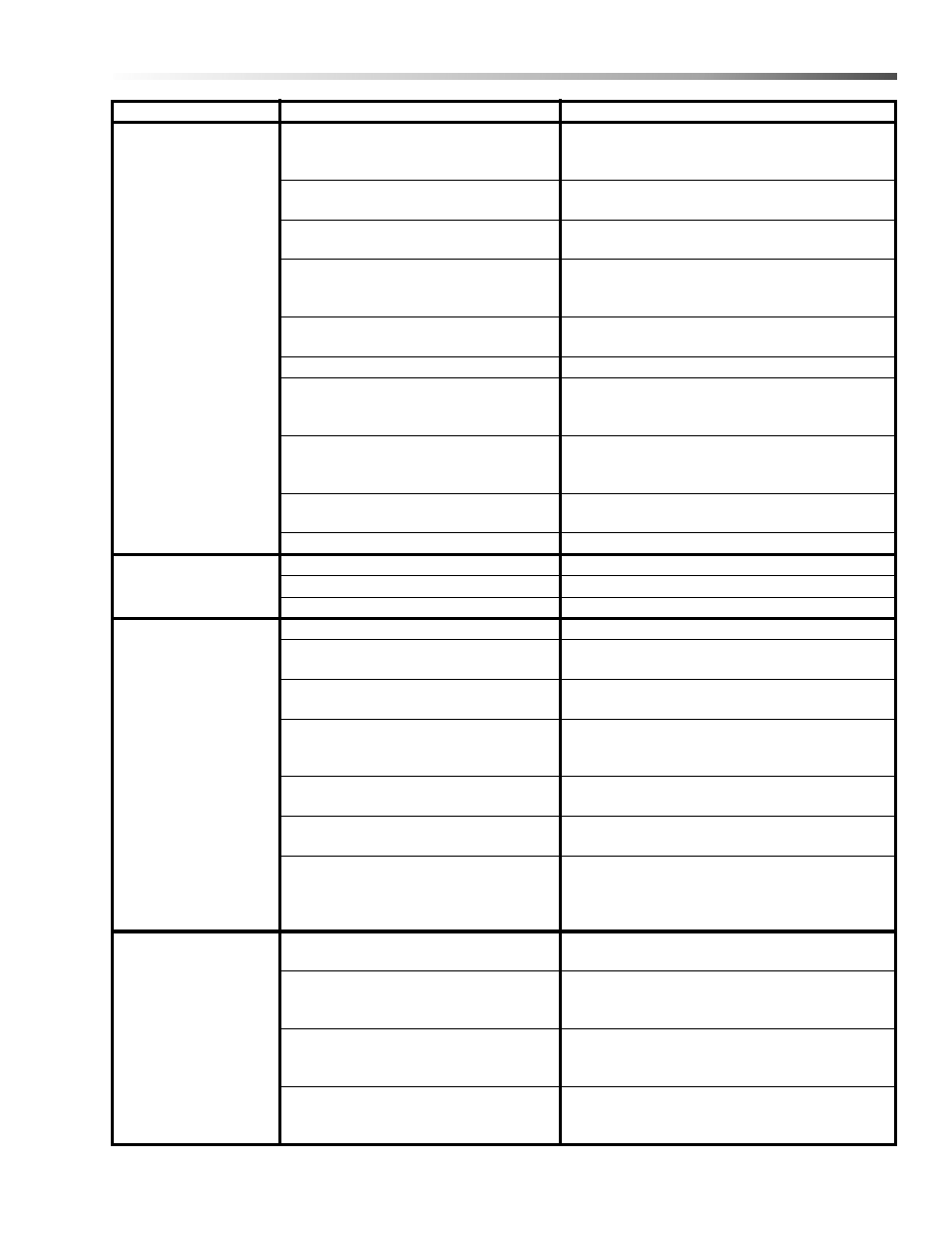

Maintenance

Problem Cause

Solution

Loss of vacuum

While cleaning, the

vacuum is not up to

specification. Engine

RPM is normal.

Vacuum gauge is giving an improper

reading.

Examine the tubing between the vacuum relief

valve and the vacuum gauge and remove any

blockage.

Vacuum hose(s) is damaged, causing a

suction leak.

Inspect hose(s), repair or replace.

Waste tank gaskets not sealing properly,

not positioned properly

Inspect the gaskets. Repair or replace as necessary.

Re-position lid, inlet and outlet

Plugged vacuum hose or vacuum

plumbing between vacuum inlet and

strainer basket.

Unplug vacuum hose or inlet plumbing.

Waste tank filter or strainer basket is

plugged.

Clean or replace filter. Clean strainer basket.

Loose vacuum pump drive belts.

Tighten the drive belts

Waste tank drain valve is damaged or

left open, causing a vacuum leak.

Close drain valve, if open. Remove the drain

valve and, after inspecting, replace the defective

components.

Vacuum relief valve requires adjustment

or has a vacuum leak due to damaged

diaphragm.

Re-adjust the vacuum relief valve. If the vacuum

does not increase, remove and inspect the relief

valve diaphragm. If damaged, replace

Vacuum exhaust heat exchangers are

plugged with lint.

Remove and clean.

Vacuum pump is worn out.

Replace the vacuum pump.

Excessive vacuum

Improper throttle adjustment.

Adjust throttle to set desired vacuum pressure.

Vacuum obstruction

Inspect hoses for obstructions.

Vacuum relief valve requires adjustment. Readjust the vacuum relief valve.

Loss of chemical

With the cleaning tool

valve open, no

chemical

Chemical pump is improperly primed.

Refer to chemical pump priming instructions.

The strainer at the inlet end of the

chemical inlet tube is clogged

Unclog the strainer. If damaged, replace.

Suction leak in the inlet tube leading into

the chemical pump.

Inspect inlet tube and flow meter for damage and

replace, if required.

Chemical pump check valve(s) is

clogged

Remove any debris from the chemical check

valve(s). Replace chemical check valve(s) or

seals, if necessary.

Chemical prime/on-off valve or chemical

metering valve is defective.

Replace valve(s).

Chemical pump diaphragm is ruptured.

Disassemble the chemical pump and replace the

damaged diaphragm and plastic disk.

Defective cylinder in the

solution pump.

Measure the pump volume. If the pump volume

is less than normal, refer to "Loss of Pump

Volume" in the Troubleshooting section in this

manual.

Chemical flow meter

indicates flow with the

tool valve closed

External leak in chemical piping

Tighten fittings. Re-apply thread sealant where

required. If any fittings are damaged, replace.

Outlet check valve is full of debris or

damaged, not allowing it to close

properly

Close the chemical valve on the chemical panel.

If the flow meter does not indicate flow, remove

debris or replace check valve, if necessary.

Chemical pump diaphragm is ruptured

Close the chemical valve on the chemical panel.

If the flow meter still indicates flow, replace the

chemical pump diaphragm and plastic disk.

Internal leak in chemical valve causing

continual flow through prime tube

returning to waste tank.

Tighten valve packing nut (see "General Service

Adjustments" section in this manual). Replace

valve, if necessary.

86341750 APEX GTX