Alicat P Series Pressure Gauge User Manual

Page 33

33

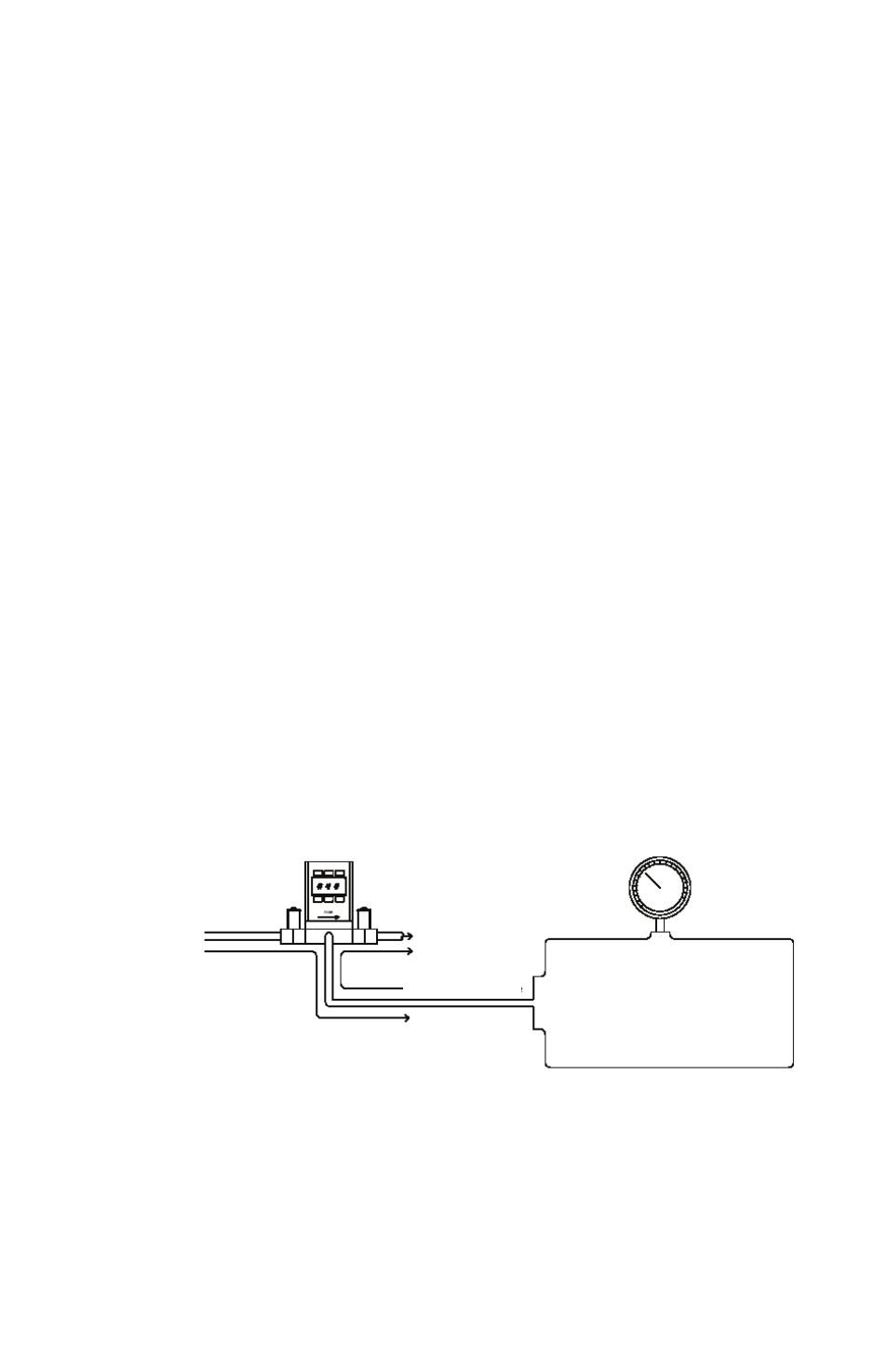

PCD-SERIES DUAL VALVE PRESSURE CONTROLLER OPERATION

Alicat Scientific PCD-Series Closed Volume Pressure Controllers incorporate a

digital pressure gauge with dual control valves and circuitry. The integrated PID

loop measures the pressure, compares it with the set-point, and adjusts either

the Inlet or Exhaust valve accordingly in excess of two thousand times per second.

It is most common to have a .050 inch diameter orifice in the inlet valve, and

a .050 inch diameter exhaust valve. The response time of the system will

depend on the size of the volume being controlled and the feed pressure. The

controllers are intended for use with clean, non-corrosive gases only.

They are designed with a feed port, a process port, and an exhaust port. This

allows the controllers to raise and lower the pressure of a closed system within

the operating range of the controller without wasting gas under constant

pressure conditions.

Plumbing

Connect your PCD into your process via the 1/8” NPT port on the front of the

unit. This is the “Process” port.

Connect a supply pressure greater than the full scale pressure control range of

the device, not to exceed 145 psig, to the inlet 1/8” NPT port on the left side

device. This is the “Inlet” port.

The 1/8” NPT “Exhaust” port, located on the right side of the device can vent to

atmosphere if the application is suitable, or to a collection network if necessary.

The pressure at the exhaust port should be at atmospheric pressure or below to

allow the controller to be used over its full scale range.

If desired, there are two 8-32 mounting holes located on the bottom of the unit

as shown in the dimensional drawing on page 52.

Connect your PCD to power and output lines as detailed on pages 9 - 12.

Supply Pressure

Closed Volume

Decrease Pressure

Exhaust

Increase Pressure

Typical PCD Plumbing Diagram