Message area, 1 warning label error (code no. 000h – 07fh) – IAI America RCM-P User Manual

Page 60

52

9. Message

Area

In the message screen, content during error and warning will be displayed.

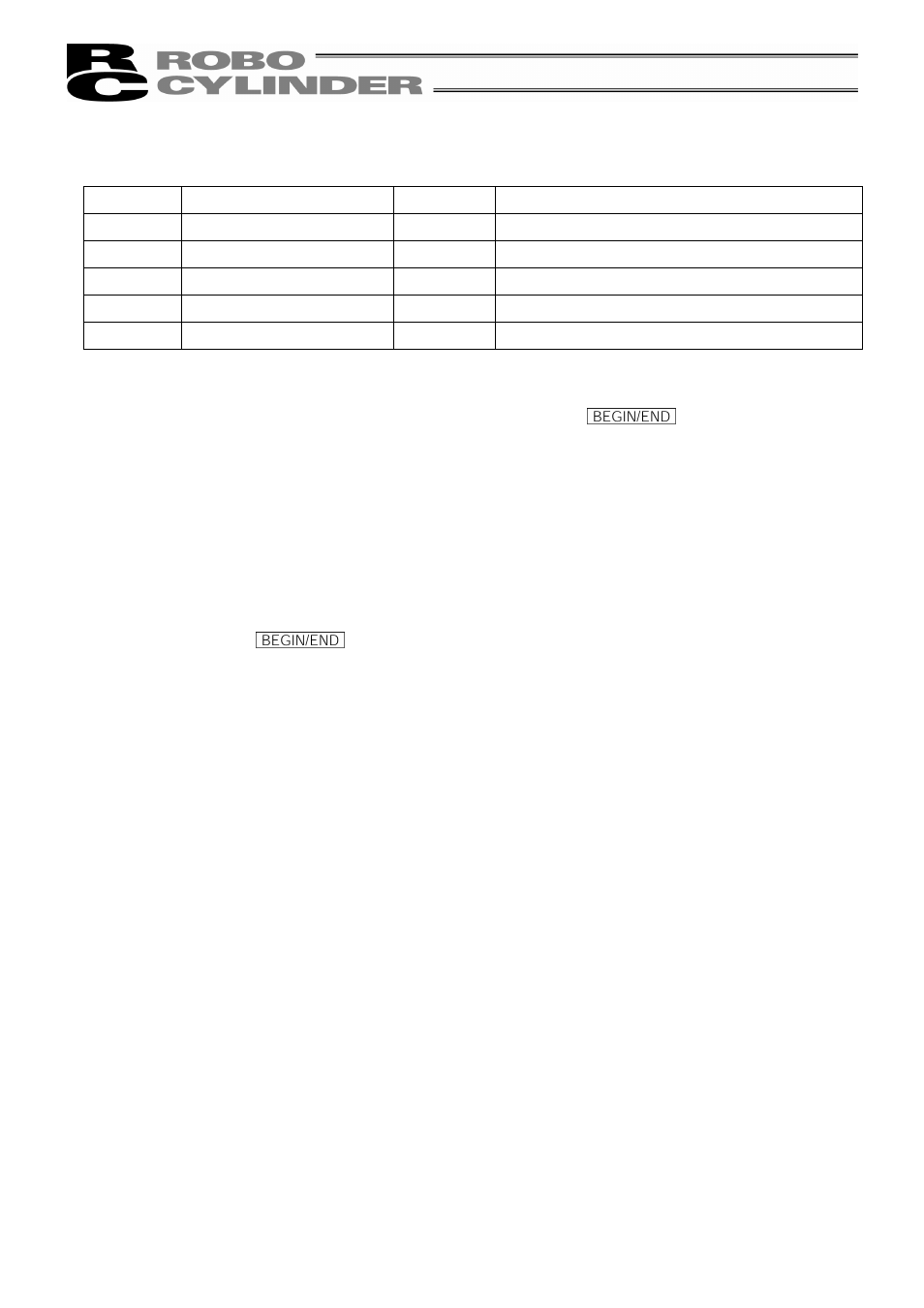

Code No.

Error Label

Error Reset

Reference

000~07F

Controller Warning

Yes

Controller rejects command

080-0FF

Controller Error

Yes

Error inside the controller

100~1FF

DIP* Message

Yes

Input error, guide message, etc.

200~2FF

DIP* Movement Release

Yes

Movement continuation impossible

300~3FF

DIP Cold Start Error

No

DIP Power install or reconnect are necessary.

* TB in the table mean RC Data Input Pendant.

* Refer to the “9.3 Controller Error.”

* For an error which can be reset, the error is reset by pressing the

key on the key sheet.

And all of the error lists in the controller are cleared by the error list clear on the user adjustment. (Refer

to 8.11.3.)

9-1 Warning

Label

Error

(Code No. 000h – 07Fh)

Warning message is cleared by recovery procedure as follows:

Release operation:

1. First, confirm the cause of the warning and resolve the problem.

2. Press down

key.

Warning is probably due to the following possibilities:

- RS485 communication abnormality

- RC Data Input Pendant operational mistake

a) RS 485 communication related abnormality

Indicates occurrence of any abnormality on the RS485 communication line.

Code No: 05Ah, 05Bh, 05Dh, 05Eh, 05Fh (Communication error detected by the controller)

Cause:

(1) RS 485 communication related abnormality

For example, when move command is delivered by PIO signal from teaching

while communicating to other devices (PLC), “075h” will occur.

(2) Influence by foreign noise or connections is not properly installed.

The RC Data Input Pendant and RC controller execute packet communication

(move instruction, data transfer, etc.) at all times. At this time, when data

changes due to noise, the RC controller will determine that it is incorrect data and

will reject the data.

Solution: (1) Confirm the above causes. In the case of frequent warning occurrences, please

separately set the signal cable and power line.

(2) Be sure to use one unit to operate the RC controller.

See to it that the RC Data Input Pendant will not conflict with the PIO signal.