Gardner Bender B400 Series Eegor Hydraulic Benders User Manual

Page 5

5

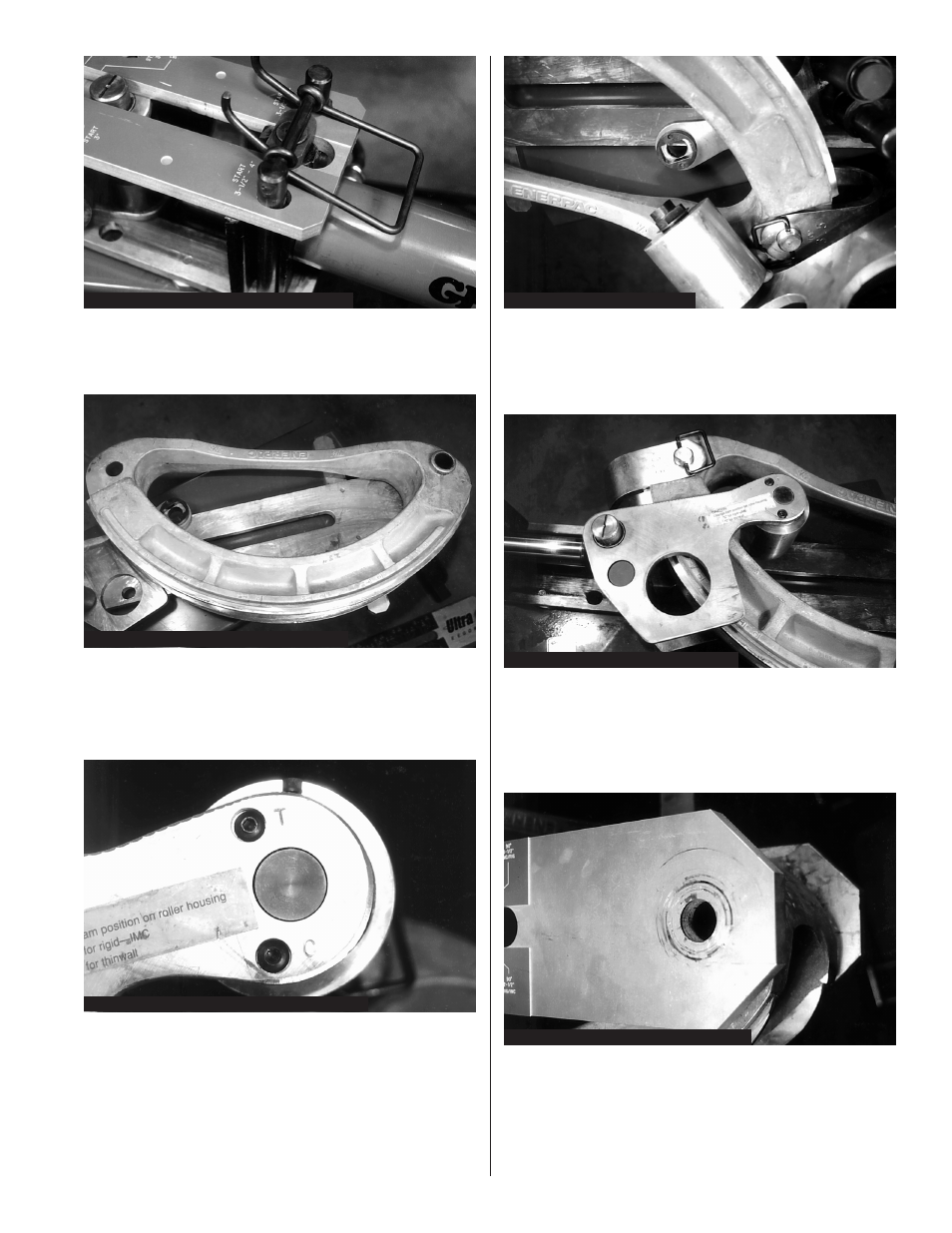

2. Position the desired size shoe on top of the lower

roller and plate assembly. Be sure the bend angle

numbers are facing up. Figure 9.

Figure 8: Locating B400L Hydraulic Cylinder

Figure 9: Positioning Bend Shoes on B400L

3. The top plate and roller assembly is installed over

the shoe. Prior to installation, move the indicator

knob to the “C” position for rigid or IMC conduit;

the “T” position for EMT (thinwall). Figure 10.

4. The large roller axle has two flats which engage

the retaining collar on the lower plate. Press the

upper plate down until the lower roller axles are

flush with the top plate holes and the flats of

the upper roller shaft are firmly seated in the

retaining collar.

Figure 10: Position Indicator Knob to “C” or “T”

Figure 11: Top Plate Installation

NOTE: The roller assembly axle may not engage the

collar initially. To ensure proper engagement,

move the indicator knob slightly until the axle

seats properly. Figure 12.

Figure 12: Correct Upper Plate Position

Figure 13: Hole Alignment Pivot Pin BZ78

5. Move the bend shoe to align the pivot hole with

the hole in the bottom frame. If the shoe is too far

away, start the hydraulic pump. Advance the

cylinder until the pivot hole is located under the

frame hole. Install the pivot pin (BZ78). Figure 13.

6. Install the “U” strap. Be sure the U-strap size

matches the bend shoe size. The stamped

numbers must face up. Position the “U” strap and

secure with pin BZ76. Figure 14.