Bending shoe and follow bar installation – Gardner Bender B400 Series Eegor Hydraulic Benders User Manual

Page 4

4

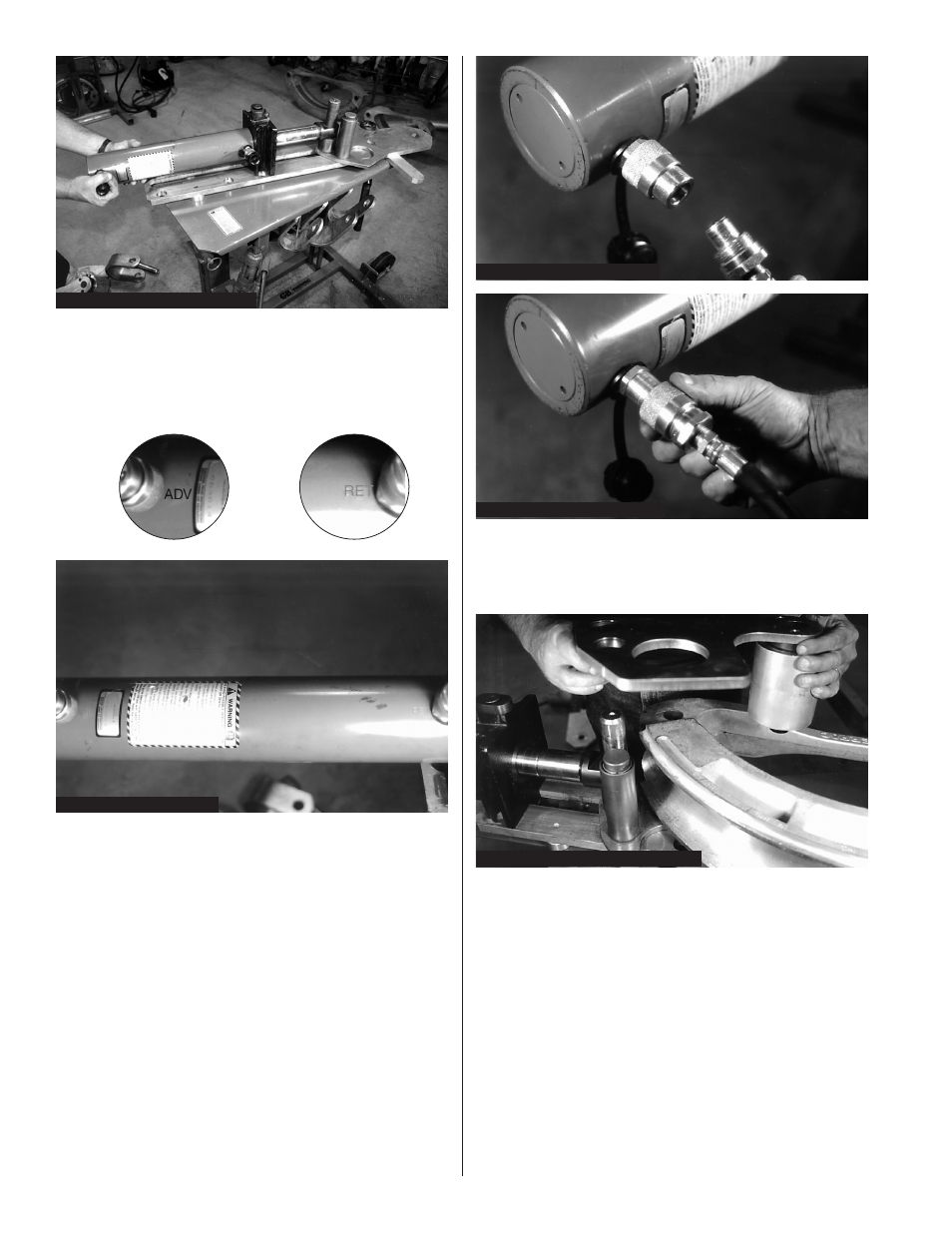

7. Remove the upper roller and plate assembly by

pulling straight up. The upper plate and large

aluminum roller are a single assembly. Figure 7.

Figure 5: Hose Installation

Figure 6A: Installing Couplers

Figure 7: Upper Roller Plate Removal

Figure 6B: Installing Couplers

Figure 4: Moving Cylinder Frame

5. Install the two hydraulic hoses. Apply one wrap of

teflon tape to the threads on the end of the hose.

Remove the pipe plugs from the pump valve, one

port is marked “ADV” the other is marked “RET”.

Install a hose in each port. Figure 5.

6. Connect the hose from the “ADV” port to the

hydraulic cylinder coupler located near the base

of the cylinder. Make sure there is no dirt or

debris in either half prior to assembly. Push the

hose coupler firmly into the cylinder coupler, then

tighten coupler collar. Connect the hose from the

“RET” port to the remaining cylinder coupler.

Figure 6A & 6B.

IMPORTANT: The hose coupler must be firmly

seated in the cylinder coupler and held

tightly while turning the coupler collar.

Hand tighten the collar.

Do not use

tools to tighten. Failure to properly

assemble couplers will inhibit oil flow.

8. The lower plate and roller assembly remain

in position during normal shoe and follow

bar installation.

Bending Shoe and

Follow Bar Installation

A. Model B400L and Model B400DL Ultra Eegor™

1. The B400L and B400DL use a 28" hydraulic

cylinder. As a result, the upper and lower plate

assemblies use the 3

1

⁄

2

"–4" frame holes for

mounting all sizes of conduit bending shoes. See

figure 8. For smaller sizes of conduit, the cylinder

plunger must be advanced to position the roller

assembly against the follow bar.