Operation – Bosch GKE 35 BCE Professional User Manual

Page 26

26 | English

1 609 929 V11 | (23.8.11)

Bosch Power Tools

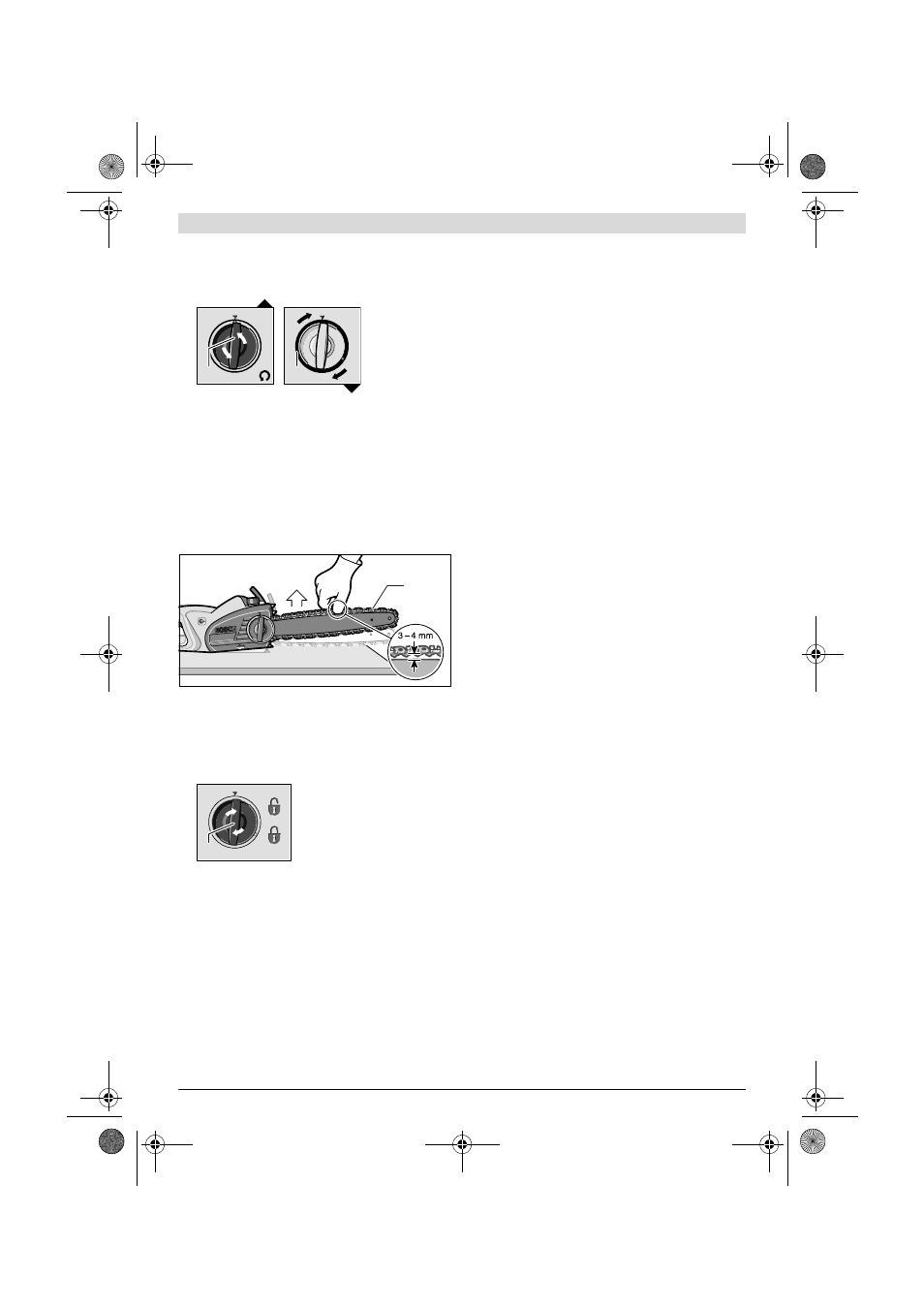

– Turn locking knob 14 approx. 1 – 3 turns anticlockwise to

loosen the chain bar.

– Check if the chain links are correctly located in the slot

around the chain bar 11 and on the drive sprocket 18.

– Turn the red chain-tensioning ring 13 clockwise ratcheting

until the correct chain tension is reached. The ratchet

mechanism prevents the chain tension from loosening. If

the chain-tensioning ring 13 is hard to turn, loosen the

locking knob 14 further in anticlockwise direction. The

locking knob 14 may also turn, when adjusting the chain-

tensioning ring 13.

– The saw chain 10 is correctly tensioned when it can be

raised approx. 3 – 4 mm from the chain bar in the centre.

This should be done by using one hand to raise the saw

chain against the weight of the machine.

– If the saw chain 10 is overtensioned, turn the chain-ten-

sioning ring 13 in anticlockwise direction.

Clamping the Chain Bar

– When the chain 10 is tensioned, clamp the chain bar 11 by

turning the locking knob 14 in clockwise direction. Do not

use a tool for this.

Saw-chain Lubrication (see figures A–B)

Note: The chain saw is not supplied filled with oil. It is essen-

tial to fill with oil before use. Operating the chain saw without

chain oil or when the oil level is below the minimum mark will

result in damage to the chain saw.

Chain life and cutting capacity depend on optimum lubrica-

tion. Therefore, the chain is automatically lubricated with

chain oil during operation via the oil outlet 19.

Filling the oil reservoir:

– Set chain saw on any suitable surface with the oil filler cap

4 facing upward.

– Clean area around the oil filler cap 4 with a cloth and un-

screw the cap.

– Do not remove filter insert during filling.

– Add Bosch biodegradable chain saw oil until reservoir is

full.

– Avoid dirt or debris from entering the oil reservoir. Screw

on oil filler cap 4 again and tighten.

Note: Four small compensation channels allow for pressure

compensation between the oil reservoir and the environment.

For functional reasons, minor amounts of oil can escape here.

Please take care to place down the chain saw with the oil filler

cap 4 facing upward.

Note: It is important to use only the recommended biodegrad-

able oil to avoid damage to the chain saw. Never use recycled/

old oil. Use of non approved oil will invalidate the warranty.

Dust/Chip Extraction

f

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the

materials to be worked.

Operation

Starting Operation

f

Observe the mains voltage! The voltage of the power

source must correspond with the data on the type plate of

the machine.

Switching On and Off

Hold the chain saw as described in section “Working with the

Chain Saw”.

To start the machine, first push the lock-off button for the

On/Off switch 2 and then press the On/Off switch 3 and keep

it pressed.

To switch off the machine, release the On/Off switch 3.

Note: For safety reasons, the On/Off switch 3 cannot be

locked; it must remain pressed during the entire operation.

Note: Do not stop chain saw after sawing by actuating the

front hand guard 5 (activating the kickback brake).

Reduced starting current

The electronic reduced starting current limits the power con-

sumption when switching the tool on and enables operation

from a 13 ampere fuse.

Temperature Dependent Overload Protection

In case of overload, e. g., when the saw chain is dull, the mo-

tor can stop due to actuation of the thermal safety switch.

Press the reset button 25 to reset the safety switch. After-

wards, the chain saw must be operated at no-load for approx.

1 minute.

14

13

10

14

OBJ_BUCH-716-004.book Page 26 Tuesday, August 23, 2011 3:50 PM