Porter-Cable PCG6500 User Manual

Page 24

24- ENG

8. Replace dipstick and tighten

securely.

9. Reconnect spark plug cap.

10. Dispose of oil according to local or

national laws and regulations.

SpArK pLUG

(FIG. 2, 13)

Use recommended spark plugs, see

product Specifications for correct

spark plug. To ensure proper engine

operation, the spark plug must be

properly gapped and free of deposits.

If the engine has been

running, the muffler will be very hot. To

reduce the risk of injury, allow cooling

before proceeding.

1. Remove the spark plug cap.

2. Clean any dirt from around the

spark plug base.

3. Use a spark plug wrench (not

supplied) to remove the spark

plug.

4. Visually inspect the spark plug.

Replace it if the insulator is cracked

or chipped. Clean the spark plug

with a wire brush if it is going to be

reused.

Risk of unsafe

operation. Always wear certified safety

equipment: ANSI Z87.1 eye protection

(CAN/CSA Z94.3) with side shields.

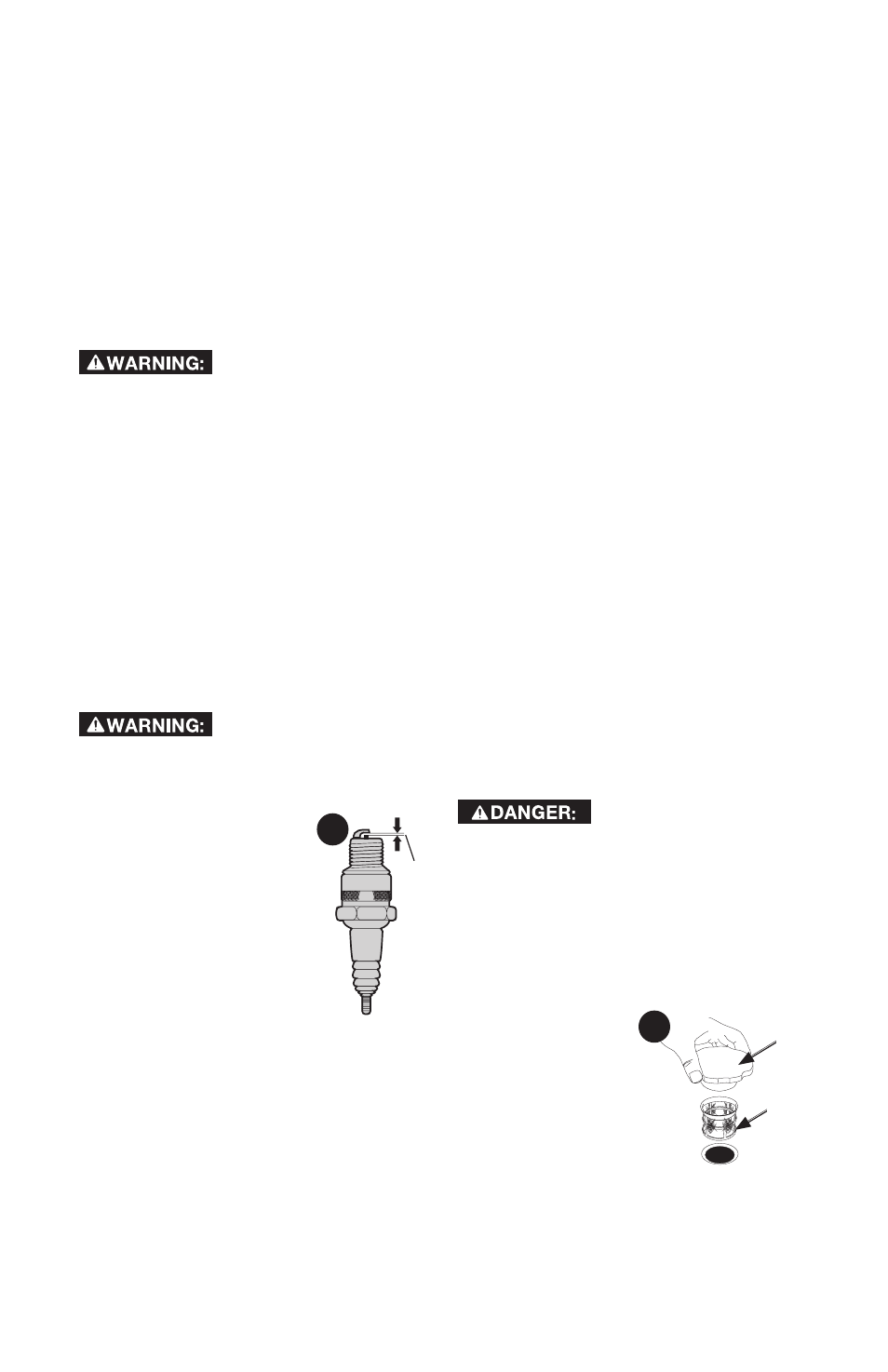

5. Measure the plug

V V

13

gap with a feeler

gauge (V V). Correct

as necessary by

carefully bending the

side electrode. See

p r o d u c t

Specifications for

correct gap.

6. Make sure the spark

plug washer is in good condition.

Thread the spark plug in by hand

to prevent cross threading.

7. After the spark plug is seated,

tighten with a spark plug wrench to

compress the washer. If installing

a new spark plug, tighten the

spark plug 1/2 turn after it seats to

compress the washer. If reinstalling

a used spark plug, tighten 1/8–1/4

turn after the spark plug seats

to compress the washer. Do not

overtighten.

8. Securely replace spark plug cap.

NOTE: The spark plug must be

securely tightened. An improperly

tightened spark plug can become

very hot and could damage the

engine. Never use spark plugs

which have an improper heat

range. Use only the recommended

spark plugs or equivalent.

DrAIN cArBUrETOr BOWL

(FIG. 1, 2)

1. Place the fuel shut off valve (G) in

the closed position (horizontal to

ground).

2. Place an OSHA-ap proved con tain er

suitable for fuel under the carburetor

bowl (P).

NOTE: Using a funnel

will allow the fuel to flow into the

container with less spillage.

3. Remove the carburetor bowl drain

(M).

4. Fuel will drain from carburetor

bowl.

5. When drained, replace carburetor

bowl drain.

cLEANING DEBrIS ScrEEN

(FIG. 1, 14)

Risk of explosion or

fire. Gasoline vapor is highly flammable.

Refuel outdoors only in well-ventilated

areas. Do not refuel or check gasoline

level while the engine is running. Do

not store, spill or use gasoline near an

open flame, a source of sparks (such

as welding), or near operating electrical

equipment.

1. Remove fuel

14

D

cap (D).

2. Remove debris

screen (QQ).

3. Clean debris

screen. Use

compressed

air to blow off

debris.