Porter-Cable PCG6500 User Manual

Page 22

22- ENG

GENErATOr

cleaning

Risk of unsafe operation.

When cleaning, use only mild soap and

a damp cloth on plastic parts. Many

household cleaners contain chemicals

which could seriously damage plastic.

Also, do not use gasoline, turpentine,

lacquer, paint thinner, dry cleaning fluids

or similar products which may seriously

damage plastic parts. Never let any

liquid get inside the tool; never immerse

any part of the tool into a liquid.

The generator should be kept clean and

dry at all times. The generator should not

be stored or operated in environments

that include excessive moisture, dust

or any corrosive vapors. If these

substances are on the generator, clean

with a cloth or soft bristle brush. Do

not use a garden hose or anything with

water pressure to clean the generator.

Water may enter the cooling air slots

and could possibly damage the rotor,

stator and the internal windings of the

alternator.

SpARk ARRESTER

Risk of explosion or fire.

DO NOT operate generator without

spark arrestor (

WW

).

If the engine has been

running, the muffler will be very hot. To

reduce the risk of injury, allow engine to

cool before proceeding.

NOTE: The spark arrester must be ser-

viced every 100 hours to maintain its

efficiency.

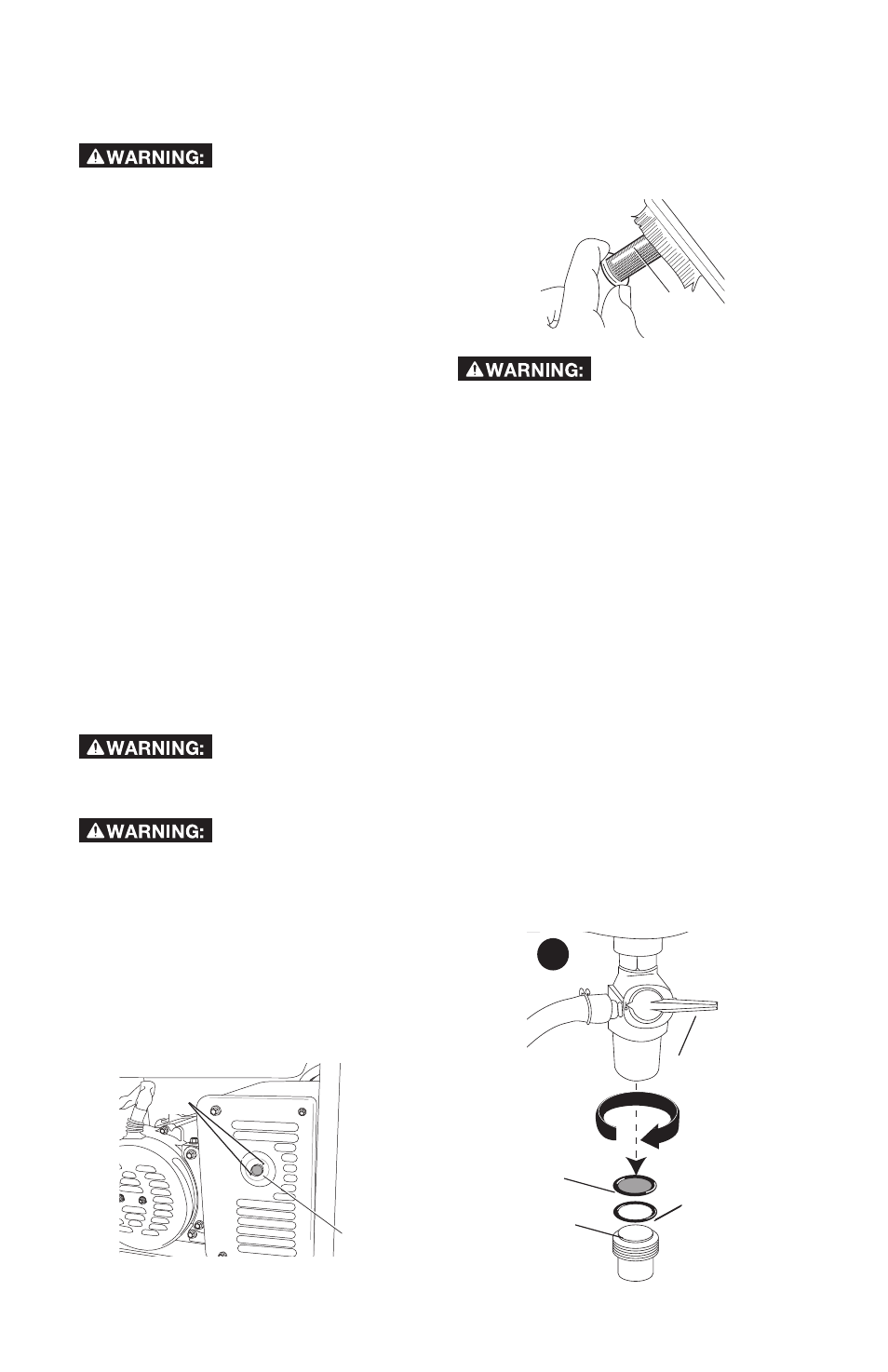

1. Remove the spark arrestor

screws (XX) and remove the spark

arrestor.

WW

XX

2. Use brush to remove carbon

deposits from the spark arrester

screen. Inspect the spark arrester

screen for holes or tears. Replace

the spark arrester if necessary.

WW

Always wear certified

safety equipment: ANSI Z87.1 eye pro-

tection (CAN/CSA Z94.3) with side shields

when removing carbon deposits.

FUEL SEDImENT cUp

cLEANING (FIG. 1, 10)

The sediment cup prevents dirt or water,

which may be in the fuel tank from

entering the carburetor. If the engine

has not been run for a long time, the

sediment cup should be cleaned.

1. Turn the fuel shut-off valve (G) to

the OFF position (horizontal to the

ground). Remove the sediment cup

(TT), O-ring (UU) and screen (SS)

as shown.

2. Clean the sediment cup, O-ring

and screen in nonflammable or

high flash point solvent.

3. Reinstall O-ring, screen and

sediment cup.

4. Turn the fuel shut-off valve to the

OPEN position and check for fuel

leaks.

SS

UU

G

TT

10