Harbor Freight Tools CENTRAL MACHINERY 93380 User Manual

Page 23

SKU 93380

For technical questions, please call 1-800-444-3353.

Page 23

5.

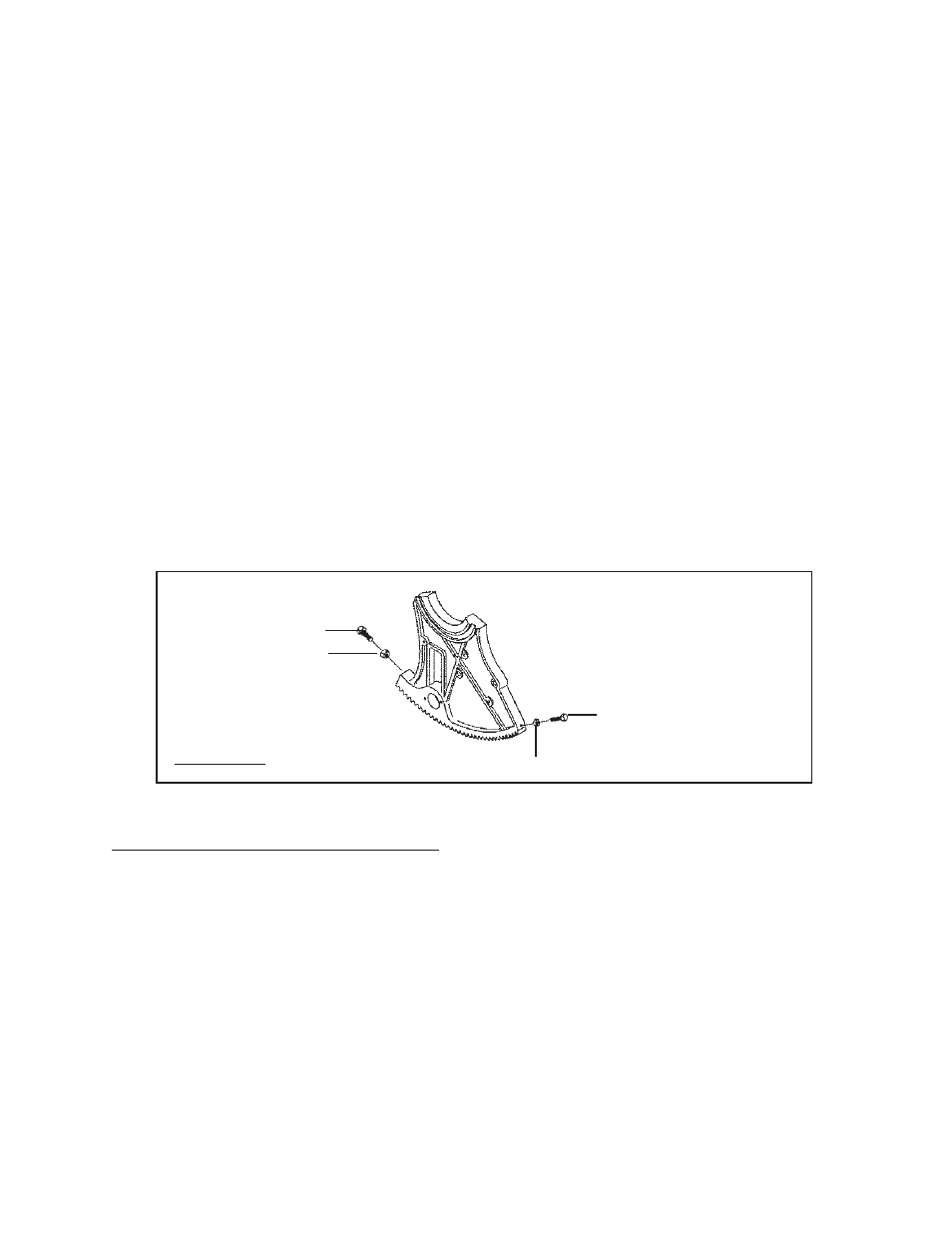

If the Saw Blade is not at 90 degrees, open the Motor Cover (2) to expose the

Geared Trunnion (52). Loosen the Nut (51) on the Geared Trunnion, and turn the

adjusting stop Bolt (50) in or out. The adjusting stop Bolt should stop against the

Geared Trunnion when the Saw Blade is 90 degrees to the Main Table (115).

Then, retighten the Nut. (See Figure U.)

6.

Set the Saw Blade at 45° to the Main Table (115) by turning the blade tilting Hand

Wheel (28) counterclockwise as far as it will go. (See Assy. Diagram.)

7.

Place a square on the Main Table (115). If the Saw Blade is not 45 degrees,

loosen the Nut (51) and turn the adjusting stop Bolt (50) in or out. The adjusting

stop Bolt should stop against the Geared Trunnion (52) when the Saw Blade is

45 degrees to the Main Table. (See Figure U.)

8.

Check the accuracy of the Pointer on the Angle Scale (9) on the front of the Table

Saw. Adjust the Pointer if necessary. (See Assy. Diagram.)

90 DEGREE

STOP BOLT (50)

NUT (51)

NUT (51)

45 DEGREE

STOP BOLT (50)

FIGURE U

To Adjust The Saw Blade Parallelism:

1.

This Table Saw will give the best results if the Miter assembly (200 thru 214) and

the Rip Fence assembly (1B thru 27B) are adjusted parallel to the Saw Blade. If

either assembly is not exactly parallel, the saw cuts and finished work will be

lower in quality. Also important, if either assembly is not exactly parallel the risk

of kickback is increased.

2.

To adjust the Saw Blade parallelism, raise the Blade Guard assembly (300 thru

315) up and out of the way of the Saw Blade. (See Assy. Diagram.)

3.

Select a tooth on the far side of the Saw Blade and directly over the Table Insert

(116A, 116B). Mark the tooth with a marker. Measure the distance from the